Ship high transmission loss base structure

A technology of transmission loss and base, applied in the direction of ships, ship propulsion, ship components, etc., can solve the problems of inability to realize multi-variable comprehensive optimization, lack of further understanding, neglect of elastic deformation of foundation and equipment, etc., and achieve good low-frequency vibration isolation Effectiveness, versatility, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is described in more detail below in conjunction with accompanying drawing example:

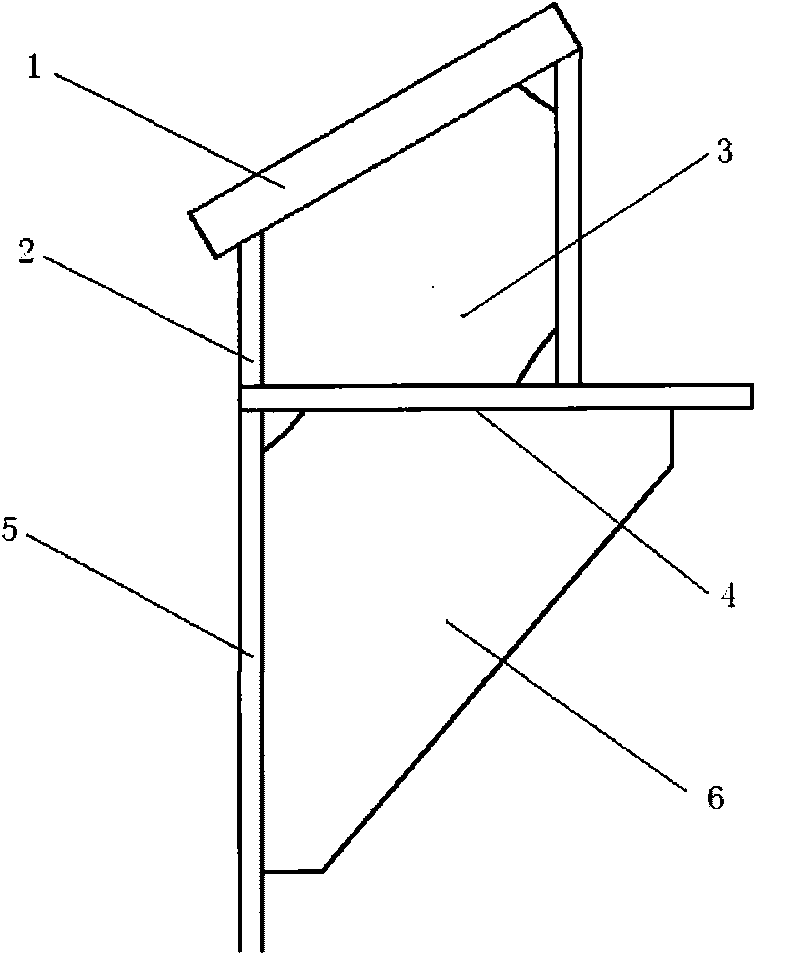

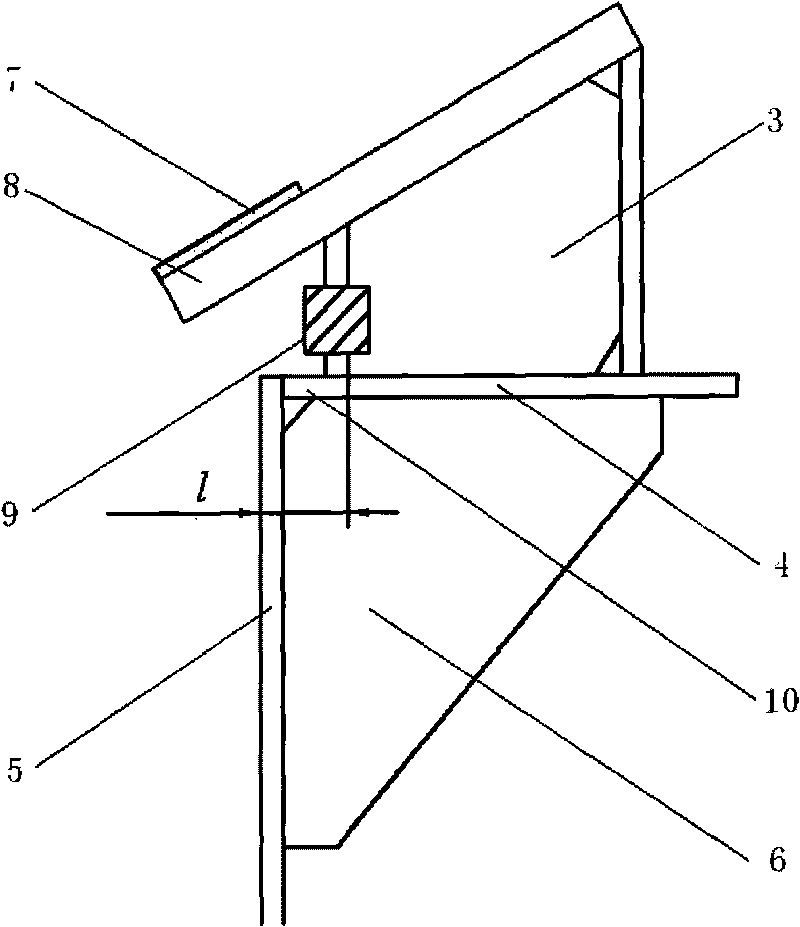

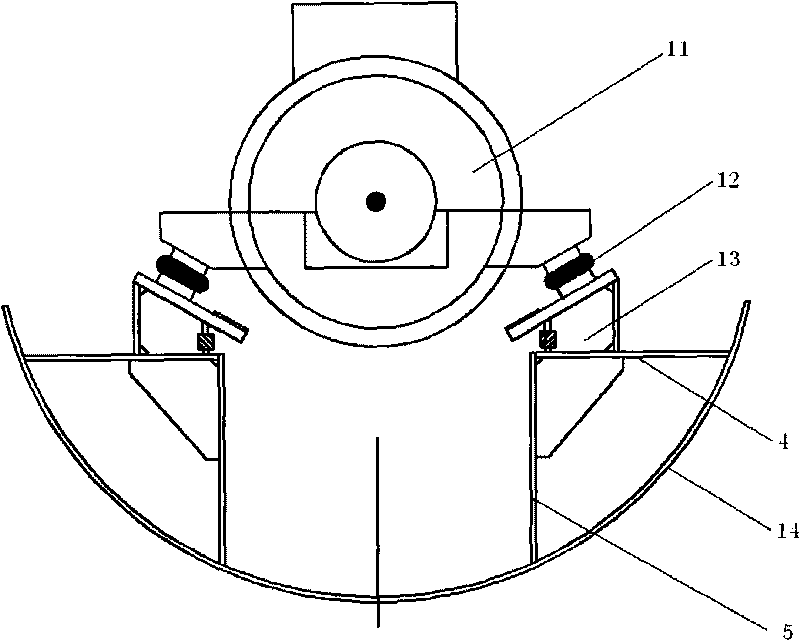

[0025] combine figure 2 , the ship high transmission loss base structure of the present invention comprises the base structure main body that is formed by base panel, base web, base bracket 3 connections, is made up of transverse mounting frame 4, vertical mounting frame 5 and The connecting mechanism composed of supporting brackets 6; the base panel has an extended base panel 8 protruding from the base web, and a vibration-absorbing covering layer 7 is arranged on the extended base panel; the base web and the vertical mounting plate The misplaced installation between the frames, that is, the web of the base is indented for a certain distance from the vertical mounting frame, forming a T-shaped, cross-shaped base connection form to connect the base of the ship with the mounting frame; the web of the base is set Anti-vibration quality9. The vibration-damping mas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com