Shock-insulation support of light free-standing equipment

A technology of shock-isolation bearings and equipment, which is applied in the direction of non-rotational vibration suppression, etc., can solve the problems of not being able to meet the needs of light-weight floating equipment for shock-isolation and vibration reduction, inability to distinguish the degree of damage and failure of components, and the disintegration of floating equipment structures, etc., to achieve Good shock isolation and vibration reduction effect, compact structure, good limit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

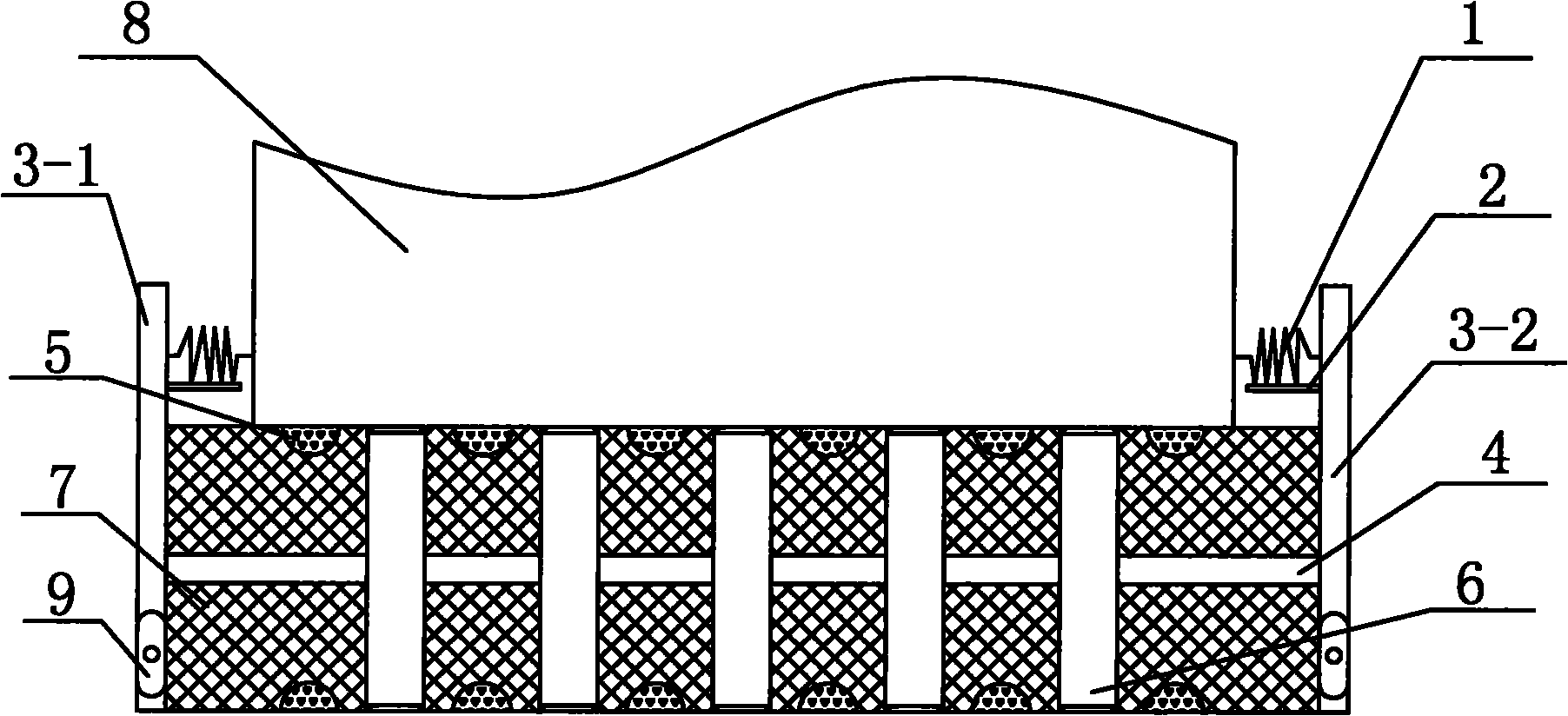

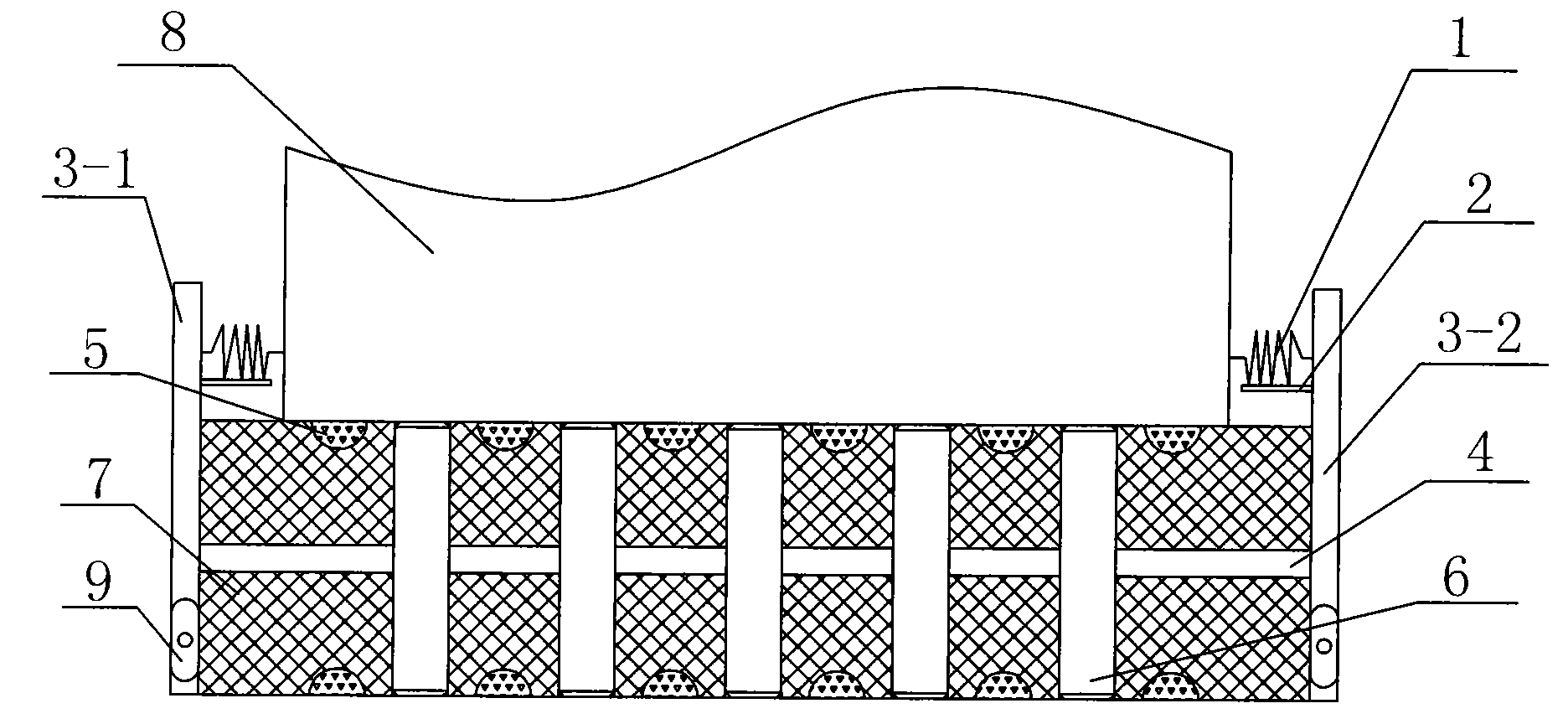

[0024] Such as figure 1 , a shock-isolation support for light-duty floating equipment according to the present invention, comprising two symmetrically arranged limiting plates 1 3-1 and 2 3-2 and set on the limiting plates 1 3-1 and 2 3 The elastic body 7 between -2, the interior of the elastic body 7 is inlaid with a plurality of high damping bodies 6 and a sandwich steel plate 4, and the upper and lower ends of the elastic body 7 are provided with evenly distributed adsorption media 5. Among them, the elastic body 7 has a certain elastic modulus and horizontal stiffness, thereby ensuring the mechanical properties and elastic properties of the support, and the high damping body 6 absorbs vibrations from different directions, increases damping and prolongs the vibration period. On the other hand, in order to limit the effect well, the upper ends of the limiting plate one 3-1 and the limiting plate two 3-2 are provided with telescopic body 1 and support plate 2, and the lower e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com