Manufacturing process and manufacturing equipment of rubber vibration isolation pad

A technology for rubber vibration isolation pads and manufacturing equipment, which is applied in the direction of coating, etc., can solve problems such as failure to achieve vibration isolation effects, unenvironmental protection of adhesives, misalignment of vibration damping plates, etc., to avoid bonding failure or non-environmental protection. Harmful to the human body, good effect of vibration reduction and vibration isolation, and enhanced firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with specific embodiments and accompanying drawings.

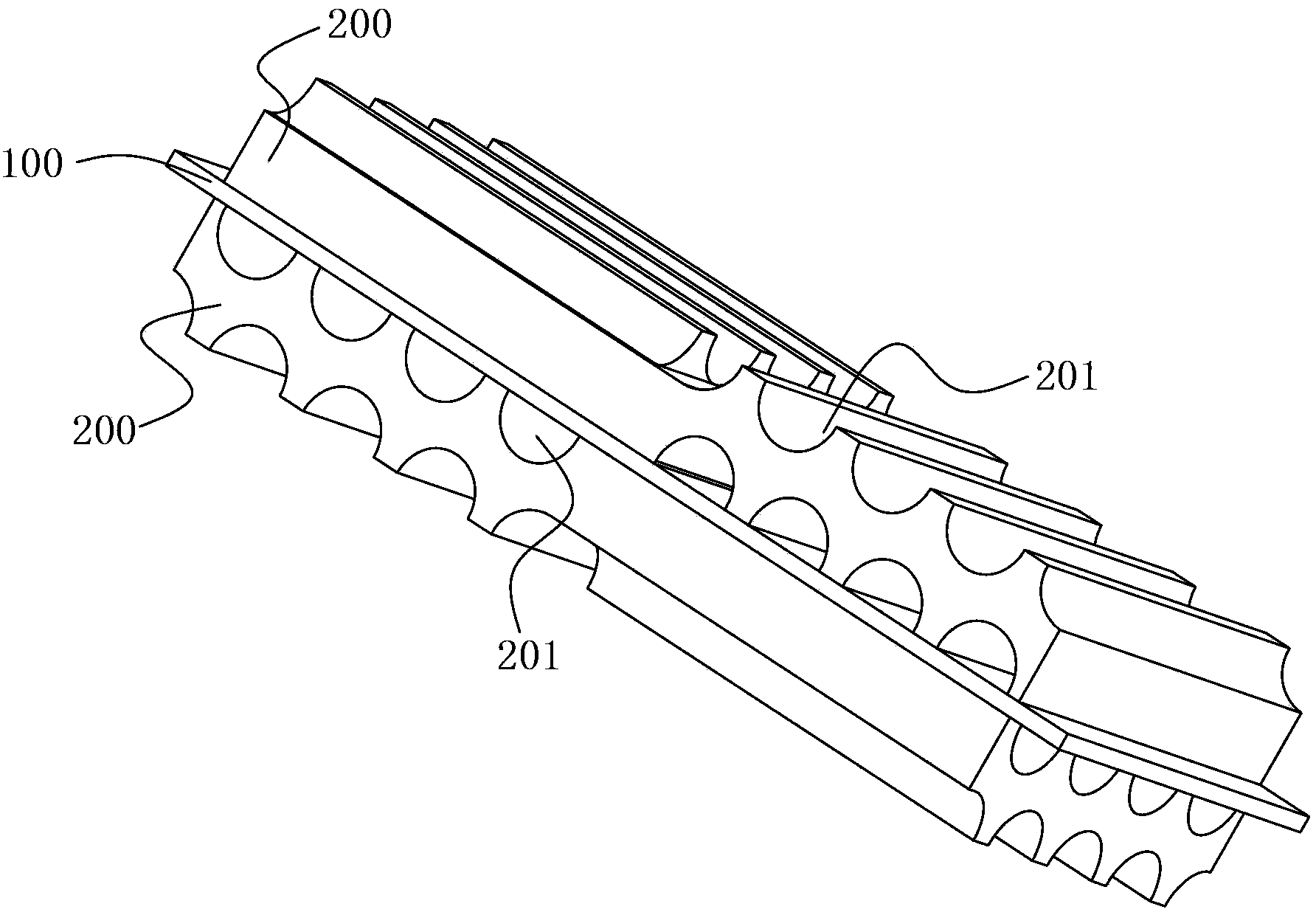

[0027] a kind of like figure 1 The manufacturing process of shown rubber vibration isolation pad, it comprises the steps:

[0028] a, it is preferable to take a thin steel plate 100 with a thickness of 1-4mm, and to punch or drill several through holes on its surface through a punching machine; wherein, the thickness of the thin steel plate 100 can be determined according to the specific requirements for vibration reduction and vibration isolation, At the same time, it can also be replaced by other material sheets with the same performance. In addition to the keel support, its function also has the effect of negative vibration reduction. The through holes on the thin steel plate 100 are mainly used to connect the vibration isolation plates 200 on both sides of the thin steel plate 100 during vulcanization forming, so as to ensure the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com