Automobile body-in-white automatic guiding lifting hanger

A technology of automatic guidance and body-in-white, applied in the direction of load hanging components, transportation and packaging, etc., can solve the problem of high configuration cost, and achieve the effect of improving the strength, high strength and high stability of the spreader

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

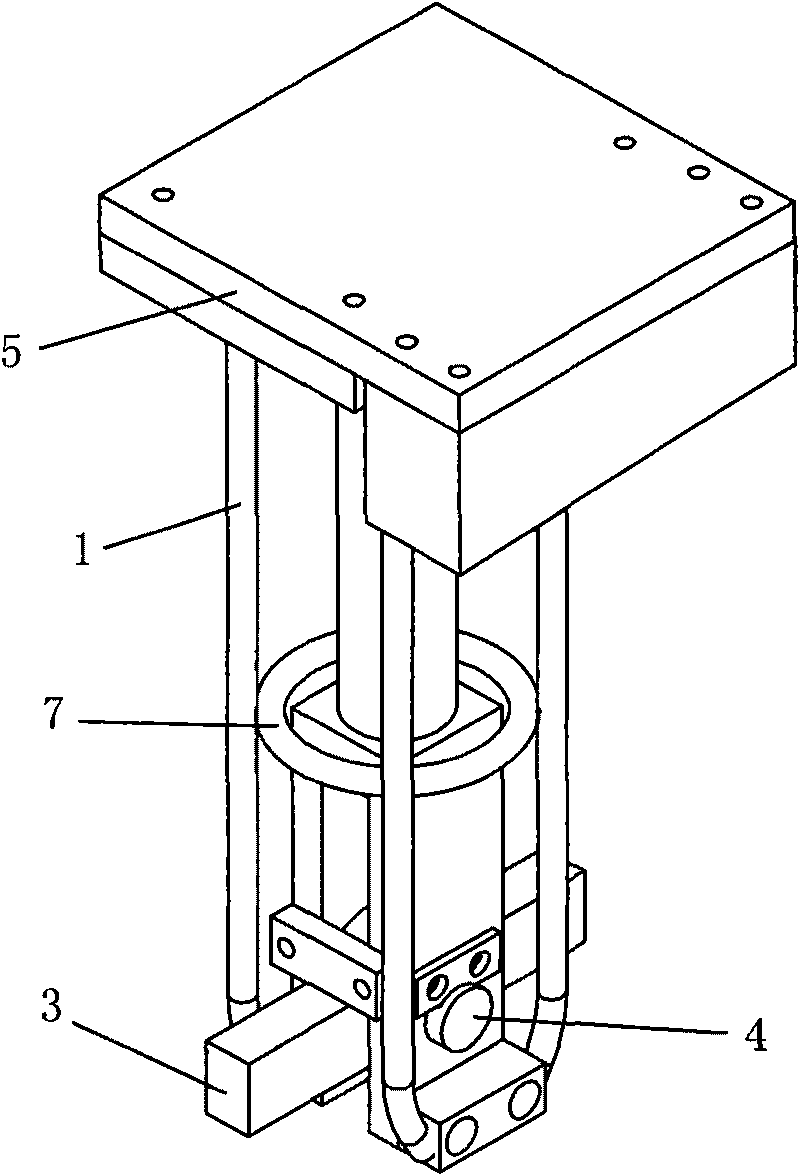

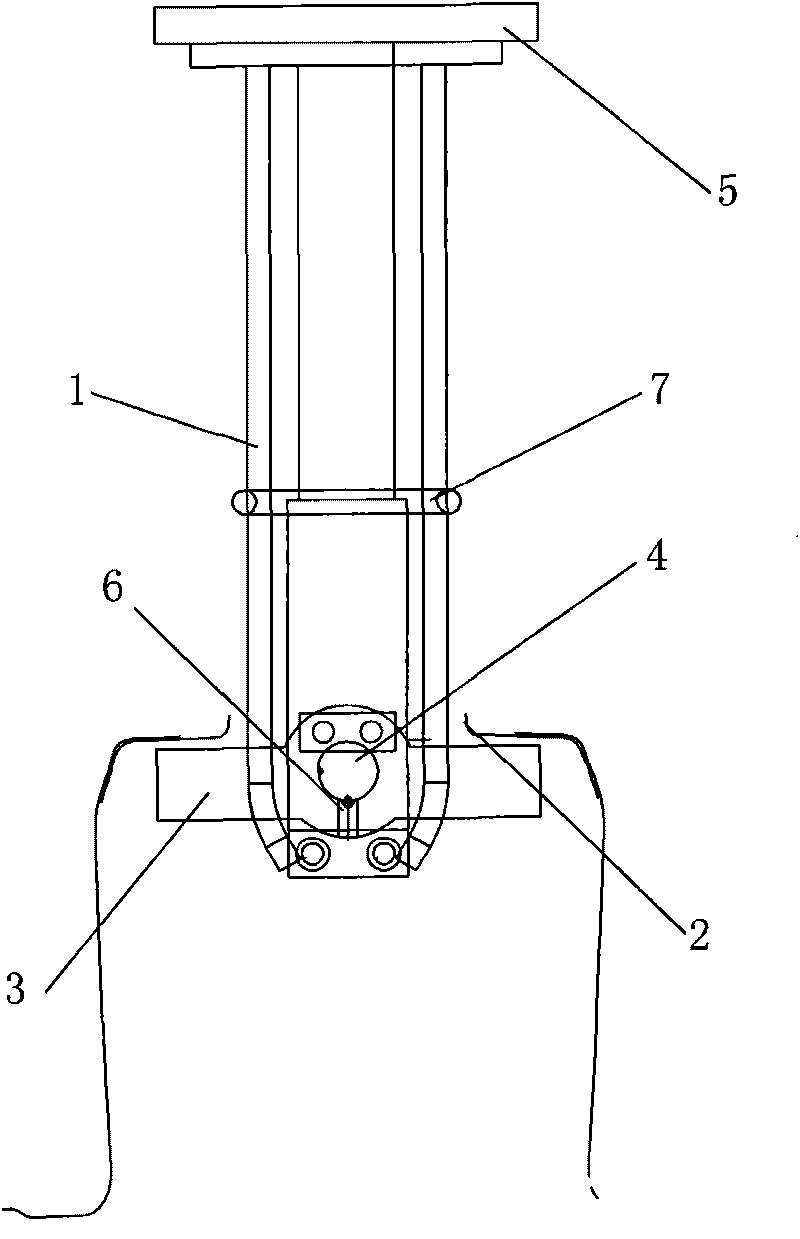

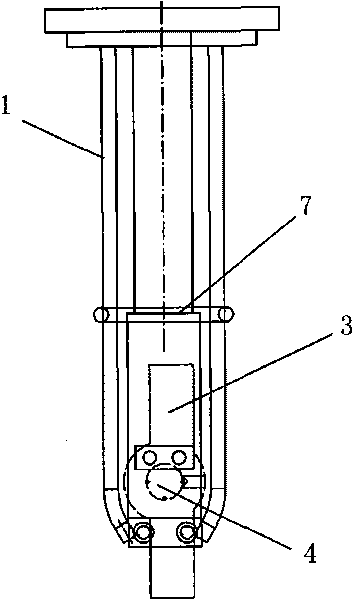

[0025] figure 1 , figure 2 with image 3 As shown, the structure of this embodiment is set as follows: a pair of "U"-shaped guide rods 1 are arranged side by side to form a four-bar frame-type longitudinal suspension rod. The inner diameter of the mounting plate hole 2; a grab bar 3 is installed on the horizontal shaft 4 positioned at the bottom end of the longitudinal suspension bar with its central axis hole, and the grab bar 3 obtains two lockable status positions by rotating at the horizontal shaft 4, One is a longitudinal bit parallel to the longitudinal boom and stowed in its four-bar frame, as figure 1 , Figure 4 shown; the other is a horizontal position perpendicular to the longitudinal suspender with both ends protruding outside the four-bar frame, such as figure 2 , image 3 As shown; the length of the grab bar 3 must be greater than the inner diameter of the front shock absorber mounting plate hole 2 in the body-in-white to be hoisted; the hoisting part 5 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com