High-frequency induction heating device

A heating device and high-frequency induction technology, applied in heat treatment furnaces, heat treatment equipment, and energy efficiency improvement, can solve problems such as poor work efficiency, difficult quenching and annealing quality, and difficulty in ensuring workpieces, and achieve improved efficiency, good quenching or annealing. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

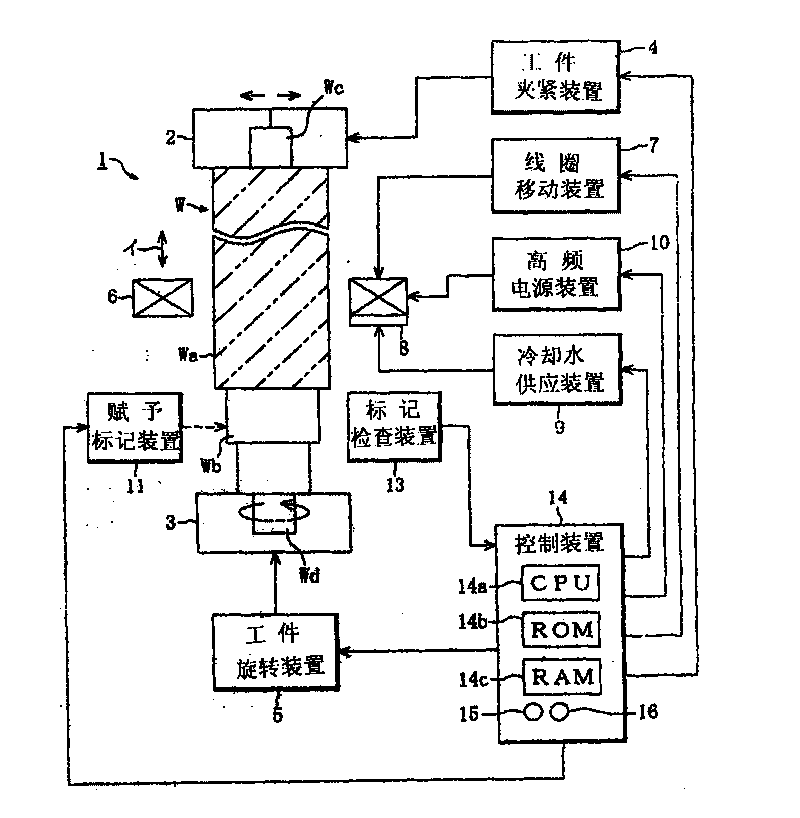

[0022] Embodiments of the present description will be described in detail below based on the drawings.

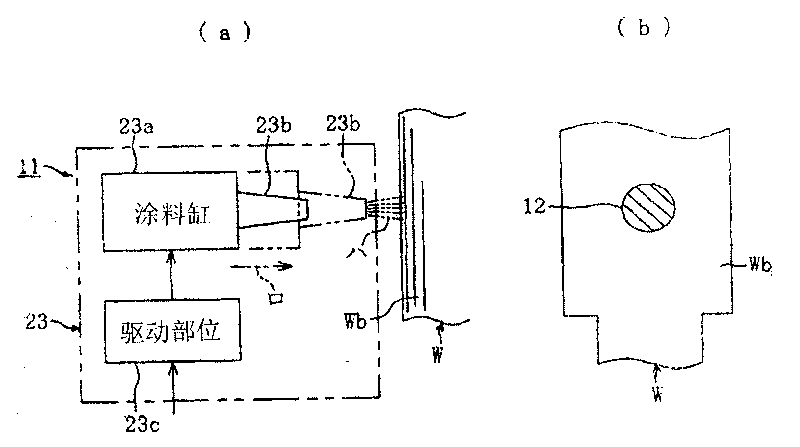

[0023] Figure 1 to Figure 6 One embodiment of the high-frequency induction heating device related to the present invention is shown. Such as figure 1 As shown, the high-frequency induction heating device 1 has the following components: an upper support member 2 and a lower support member 3 that support the upper and lower ends of a shaft-shaped workpiece W (abbreviated as a workpiece W) composed of a gear shaft or a turbine shaft as a support device, And the workpiece clamping device 4 that moves (runs) the upper supporting member 2 in a designated direction to clamp the workpiece W, the workpiece rotating device 5 that rotates the lower supporting member 3 in a designated direction, and the quenching and annealing portion Wa installed on the outer periphery of the workpiece W Side heating coil 6.

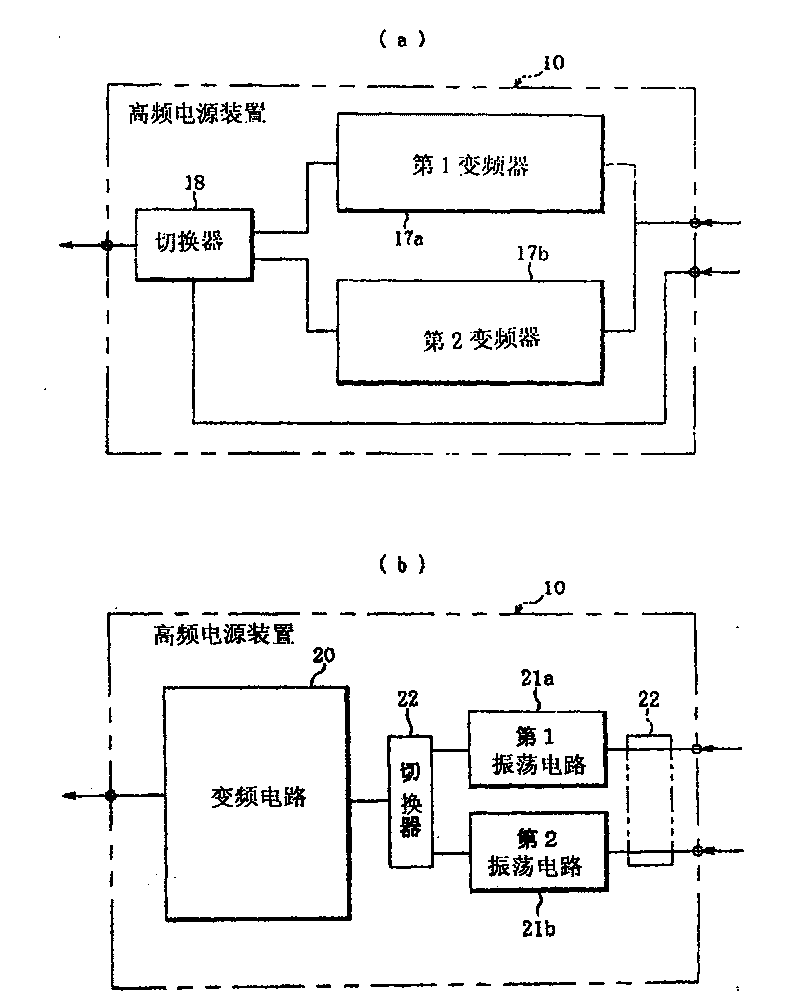

[0024] In addition, the high-frequency induction heating device 1 furth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com