Antibacterial paper and manufacturing method thereof

A production method and technology of antibacterial paper, which can be applied to paper, foam addition, etc., can solve problems such as human health threats

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The structural principle and working principle of the present invention will be described in detail below with reference to the accompanying drawings:

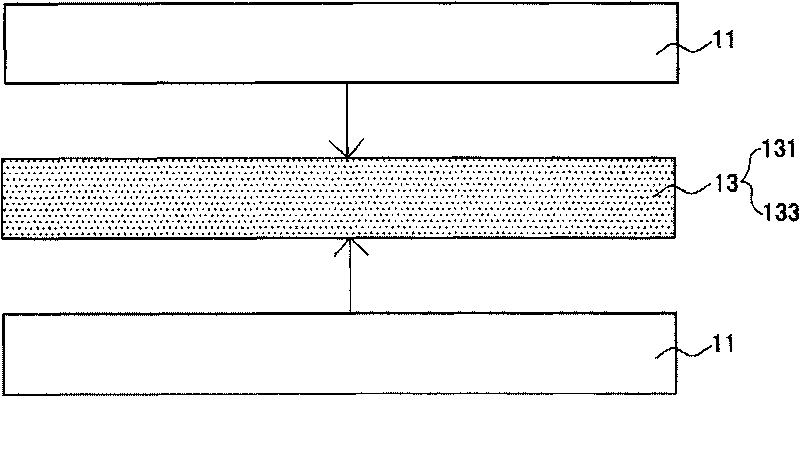

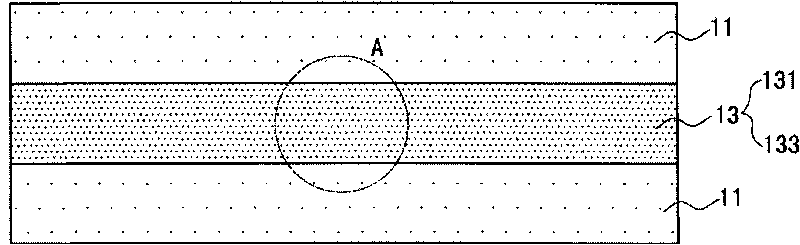

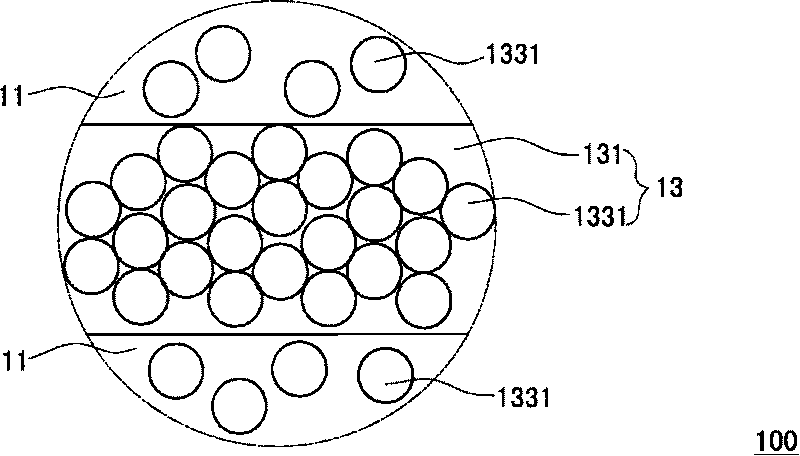

[0041] See figure 1 and figure 2 , Is a structural exploded view and structural combination view of a preferred embodiment of the antibacterial paper of the present invention, and refer to Figure 2A An enlarged schematic diagram of part A of the antibacterial paper. First, like figure 1 As shown, the present invention provides a plurality of paper layers 11 and a first adhesive 131 is stirred and mixed with a certain concentration of antibacterial agent 133 to form a first composite layer 13.

[0042] Then, like figure 2 and Figure 2A As shown, the antibacterial agent 133 is composed of a plurality of antibacterial particles 1331. A paper layer 11 is respectively provided on the upper and lower surfaces of the first composite layer 13, and the first composite layer 13 will be provided on each paper layer 11 in a fully coa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com