Production and processing technology of thick broad-bean sauce

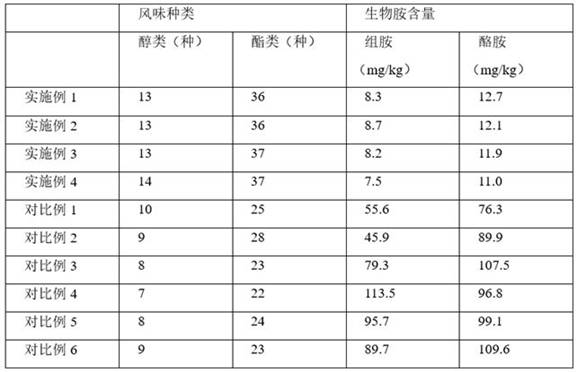

A processing technology, the technology of bean paste, which is applied in the field of production and processing technology of bean paste, can solve the problems of uneven production process of bean paste and increased content of biogenic amines, and achieve the effects of improving flavor, reducing acidity, and inhibiting the accumulation of biogenic amines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] S1 Making Douban Song

[0036] S11 Soak the washed broad beans at room temperature for 4 hours, peel the skins, and steam the peeled broad beans for 20 minutes at a temperature of 118°C to obtain steamed watercress, then gradually cool the steamed watercress to room temperature. Cool to 80°C, slowly spray lemon juice into broad beans, and mix well, the mass ratio of lemon juice to steamed watercress is 500:1;

[0037] S12 Add standard flour and Aspergillus oryzae Luyao 3042 to the cooled broad beans and mix thoroughly to obtain mixed broad beans; wherein the mass ratio of the steamed broad beans, standard flour and Aspergillus oryzae Luyao 3042 is 1000:200: 0.3;

[0038] S13 fermenting the mixed broad beans, stopping the fermentation after yellow hairs or white hairs grow on the surface of the broad beans, then gently kneading the watercress, sieving to remove dry mildew and crushed beans, to obtain watercress koji;

[0039] S2 mix

[0040] S21 sequentially add 40° w...

Embodiment 2

[0049] S1 Making Douban Song

[0050] S11 Soak the washed broad beans at room temperature for 6 hours, then peel the skins, and steam the peeled broad beans for 15 minutes at a cooking temperature of 122°C to obtain steamed watercress, then gradually cool the steamed watercress to room temperature, when Cool to 100°C, slowly spray lemon juice on broad beans, and mix well, the mass ratio of lemon juice to steamed watercress is 500:2;

[0051] S12 Add standard flour and Aspergillus oryzae Luyao 3042 to the cooled broad beans and mix thoroughly to obtain mixed broad beans; wherein the mass ratio of the steamed broad beans, standard flour and Aspergillus oryzae Luyao 3042 is 1000: 300: 0.4;

[0052] S13 fermenting the mixed broad beans, stopping the fermentation after yellow hairs or white hairs grow on the surface of the broad beans, then gently kneading the watercress, sieving to remove dry mildew and crushed beans, to obtain watercress koji;

[0053] S2 mix

[0054] S21 sequ...

Embodiment 3

[0063] S1 Making Douban Song

[0064] S11 Soak the washed broad beans at room temperature for 5 hours, peel the skins, and steam the peeled broad beans for 18 minutes at a temperature of 120°C to obtain steamed watercress, then gradually cool the steamed watercress to room temperature. Cool to 90°C, slowly spray lemon juice into broad beans, and mix well, the mass ratio of lemon juice to steamed watercress is 500:1.5;

[0065] S12 Add standard flour, Aspergillus oryzae Luyao 3042 to the cooled broad beans and mix thoroughly to obtain mixed broad beans; wherein the mass ratio of the steamed broad beans, standard flour, and Aspergillus oryzae Luyao 3042 is 1000:250: 0.35;

[0066] S13 fermenting the mixed broad beans, stopping the fermentation after yellow hairs or white hairs grow on the surface of the broad beans, then gently kneading the watercress, sieving to remove dry mildew and crushed beans, to obtain watercress koji;

[0067] S2 mix

[0068] S21 sequentially add 40° ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com