Combined vacuum preloading method foundation treatment construction method

A vacuum preloading method and construction method technology, which is applied in the fields of infrastructure engineering, soil protection, construction, etc., can solve problems such as land inaccessibility and construction difficulties, and achieve the effect of shortening the use time and requiring low surface bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

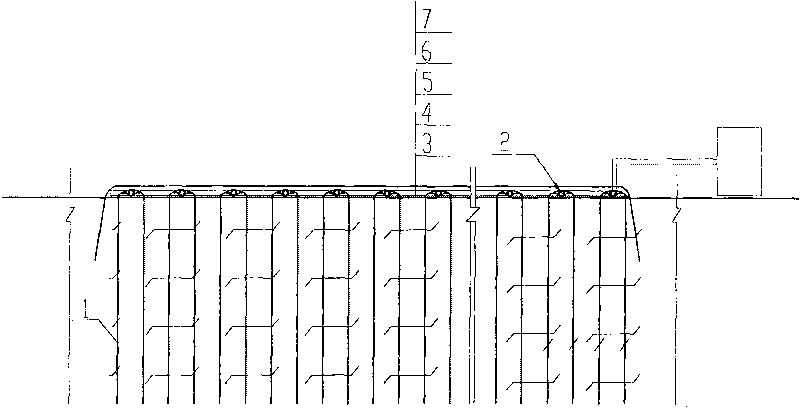

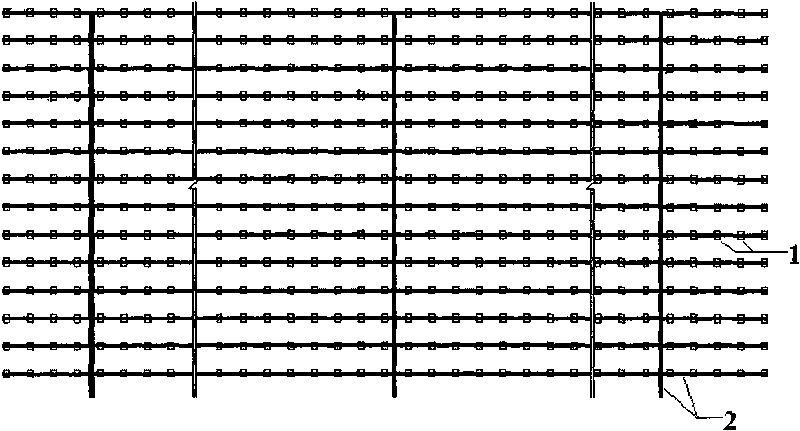

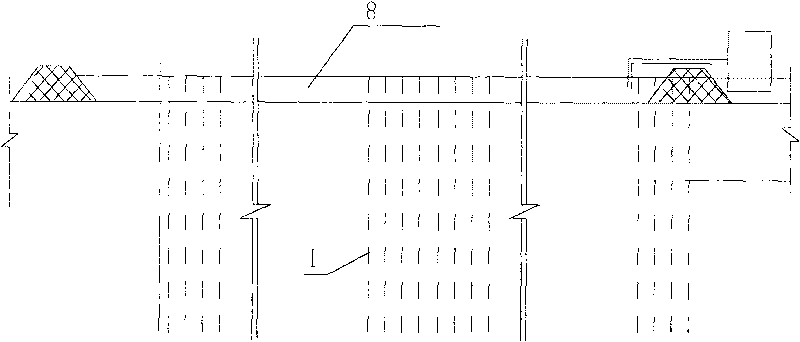

[0016] The application of the construction method of the combined vacuum preloading method foundation treatment of the present invention will be further described below in conjunction with the accompanying drawings.

[0017] The construction method of foundation treatment combined with vacuum preloading method of the present invention includes two construction processes of shallow layer vacuum preloading and deep layer vacuum preloading, the shallow layer vacuum preloading is carried out first, and then the deep layer vacuum preloading is carried out;

[0018] The construction process of the shallow vacuum preloading method includes laying woven fabrics and geotextiles on the foundation to be treated, laying plastic drainage boards, laying filter pipes, connecting filter pipes and drainage boards, laying three-dimensional geonets or geogrids, laying Plastic sealing film, vacuum pumping for 10 to 30 days;

[0019] After 10 to 30 days of shallow vacuum preloading treatment, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com