Engine part and whole airtightness detection device

An air tightness detection and engine technology, applied in the field of machinery, can solve the problems of waste of performance, unavailability, high price, etc., and achieve the effects of low input cost, simple structure and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

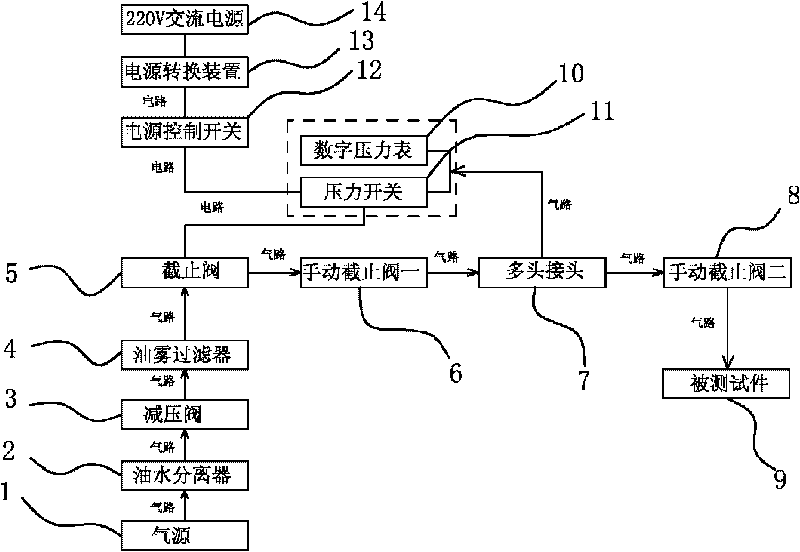

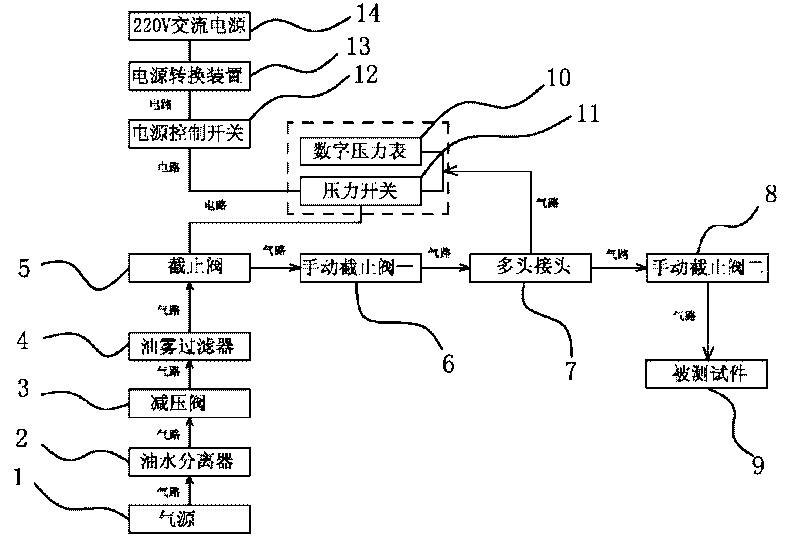

[0022] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0023] Such as figure 1 As shown, the engine components and the air tightness detection device of the whole machine include an air source 1, a shut-off valve 5, a multi-head joint 7, a manual shut-off valve 1 6, a manual shut-off valve 2 8, a digital pressure gauge 10 and various interfaces to be tested.

[0024] Specifically, the gas path of this device is as follows: high-pressure gas passes through gas source 1, oil-water separator 2, pressure reducing valve 3, oil mist filter 4, shut-off valve 5, manual shut-off valve-6, and multi-head joint 7 in sequence. The multi-head joints are bifurcated at 7 points, one path leads to the digital pressure gauge 10 and the pressure switch 11, and the other path passes through the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com