Electric cable of ink jet printer

A technology for printers and cables, used in insulated cables, cables, printing and other directions, can solve problems such as pipeline confusion, inconvenient management, and potential safety hazards, and achieve the effect of helping management and improving the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

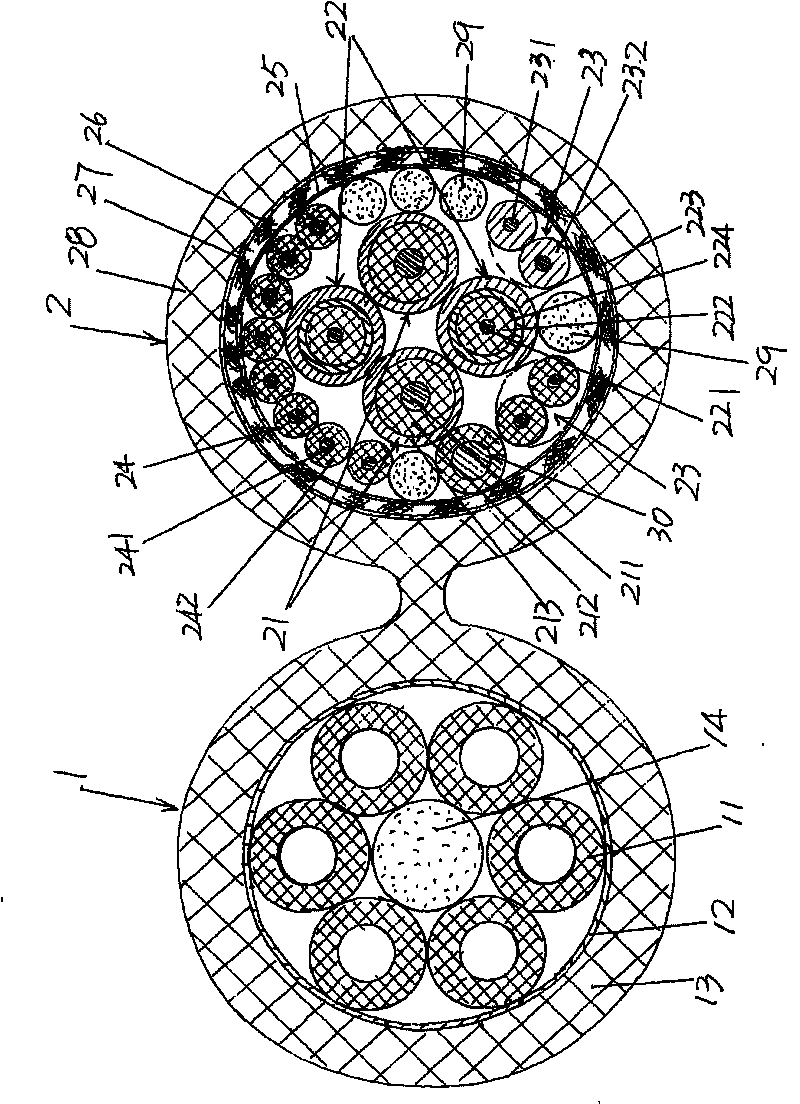

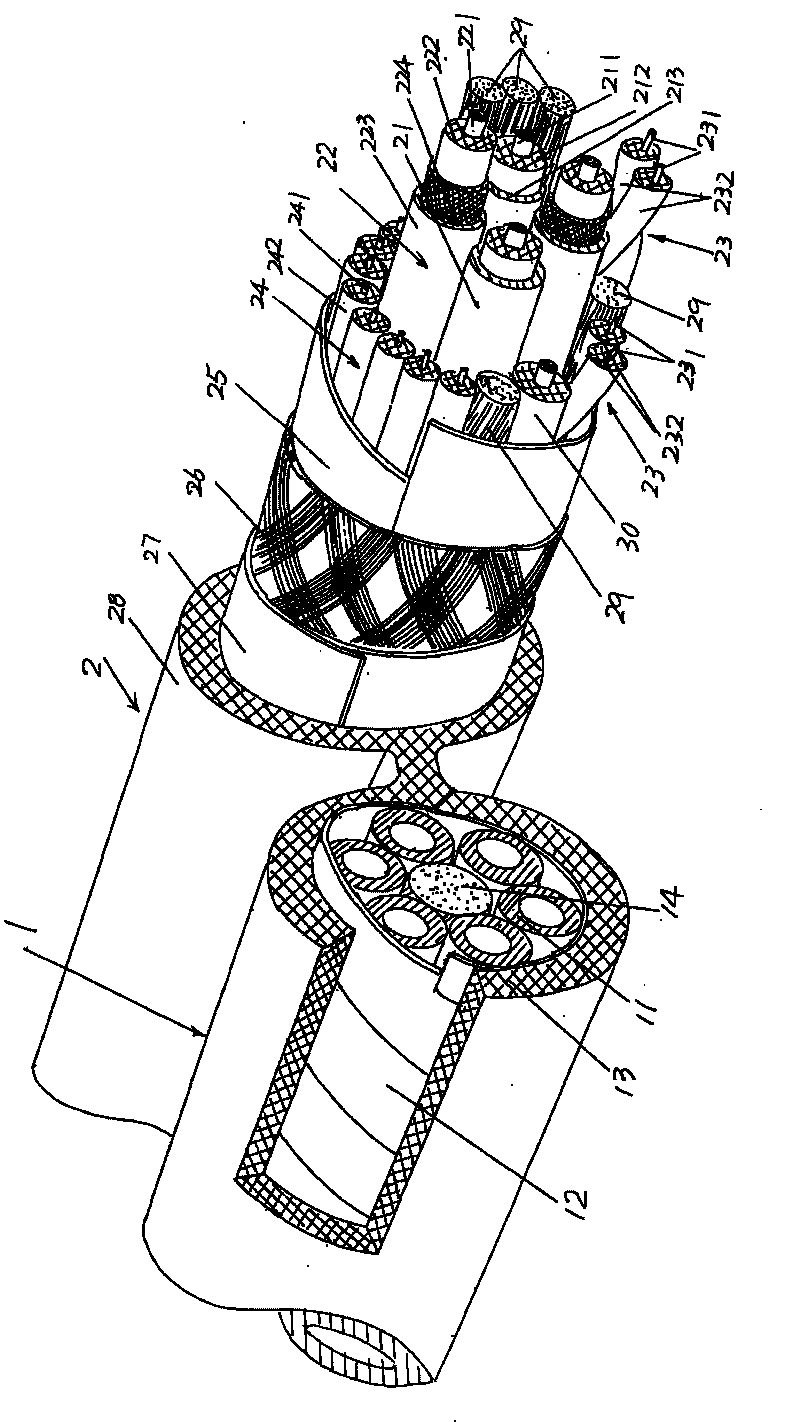

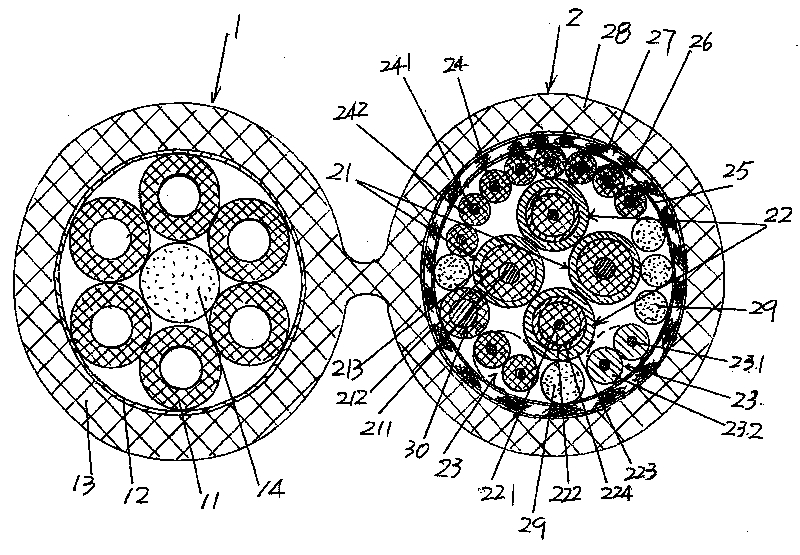

[0017] please see figure 1 with figure 2 ,exist figure 1 with figure 2 Among them, the left side is the ink supply tube assembly cable 1, and the right side is the power supply and signal line assembly cable 2. As an example, 6 ink supply tubes 11 are cited, which can provide inks of 6 different colors for the inkjet printer. , The ink supply pipe 11 is preferably made of polytetrafluoroethylene. In order to make the six ink supply tubes 11 have ideal roundness when they are assembled, that is, in order to ensure the roundness of the ink supply tube assembly cable 1, a solid and cross-sectional shape is provided in the center of the six ink supply tubes 11. The filling strip 14 is circular, and the material of the filling strip 14 does not need to be limited in the present invention, but rock wool rope or other similar materials are preferably used. Depend on figure 1 with figure 2 The six ink supply tubes 11 shown are arranged around a fill bar 14 and wrapped with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com