Inductor and manufacturing method thereof

A production method and inductor technology, applied in the manufacture of inductors/transformers/magnets, transformer/inductor cores, inductors with magnetic cores, etc., can solve the problems of slow electrode oxidation, failure, product failure, etc., to prevent Effects of slow oxidation, increased coil area, and avoidance of adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

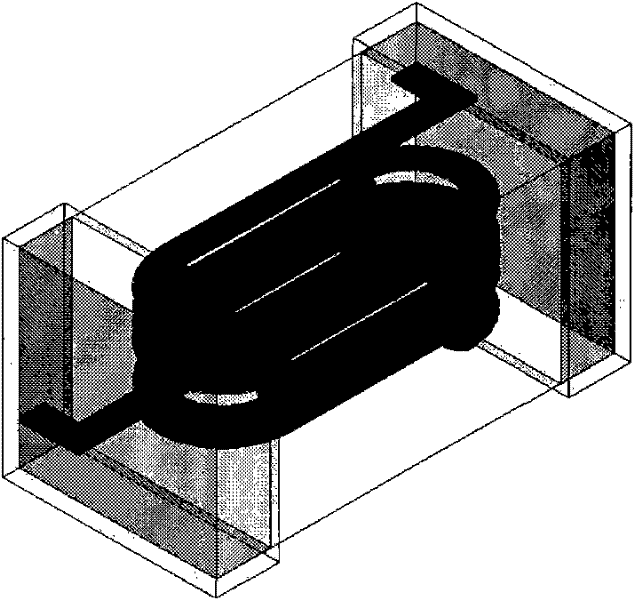

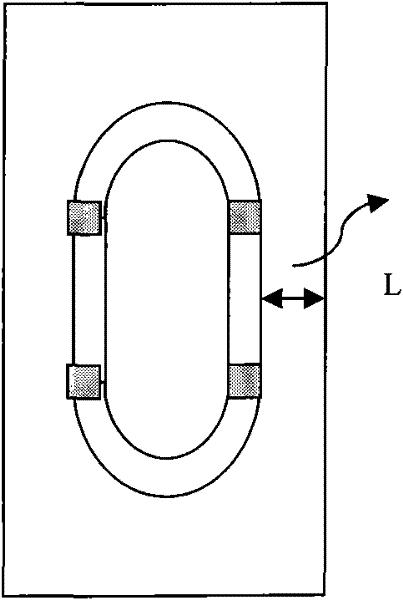

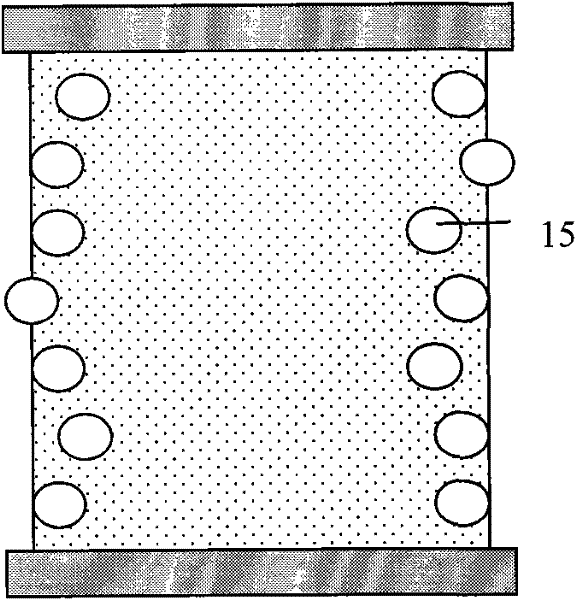

[0046] figure 2 , Figure 3a and Figure 3b A multilayer chip inductor 21 of an embodiment and its manufacturing method are shown, the inductor includes a magnet 10 and terminal electrodes 12, 13, a coil 15 is arranged inside the magnet, and the coil 15 is electrically connected to the Terminal electrodes 12, 13 (not shown), the edge of the coil 15 is close to the surface of the magnet 10, the surface of the magnet 10 is covered with a glass layer 11 except the end of the magnet, and the terminal electrodes are directly Combine with the end of the magnet.

[0047] See Figure 3a and Figure 3b According to the method of the present invention, an embodiment of manufacturing a multilayer chip inductor includes the following steps:

[0048] Step 1. Magnet preparation process

[0049] Known techniques can be used to form such Figure 3b Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com