Combined-type coil pipe air treatment device, air treatment system based on combined-type coil pipe air treatment device and using method

An air treatment device and air treatment system technology, applied in air conditioning systems, ventilation systems, pipeline layout, etc., can solve problems such as insufficient air supply volume of the fresh air system, large load of the air conditioning system, and insufficient indoor gas replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

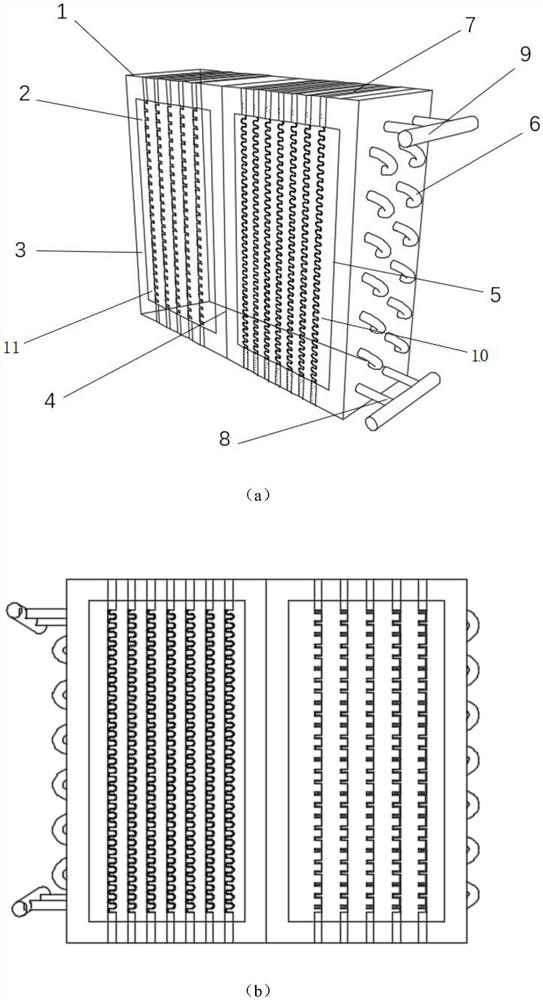

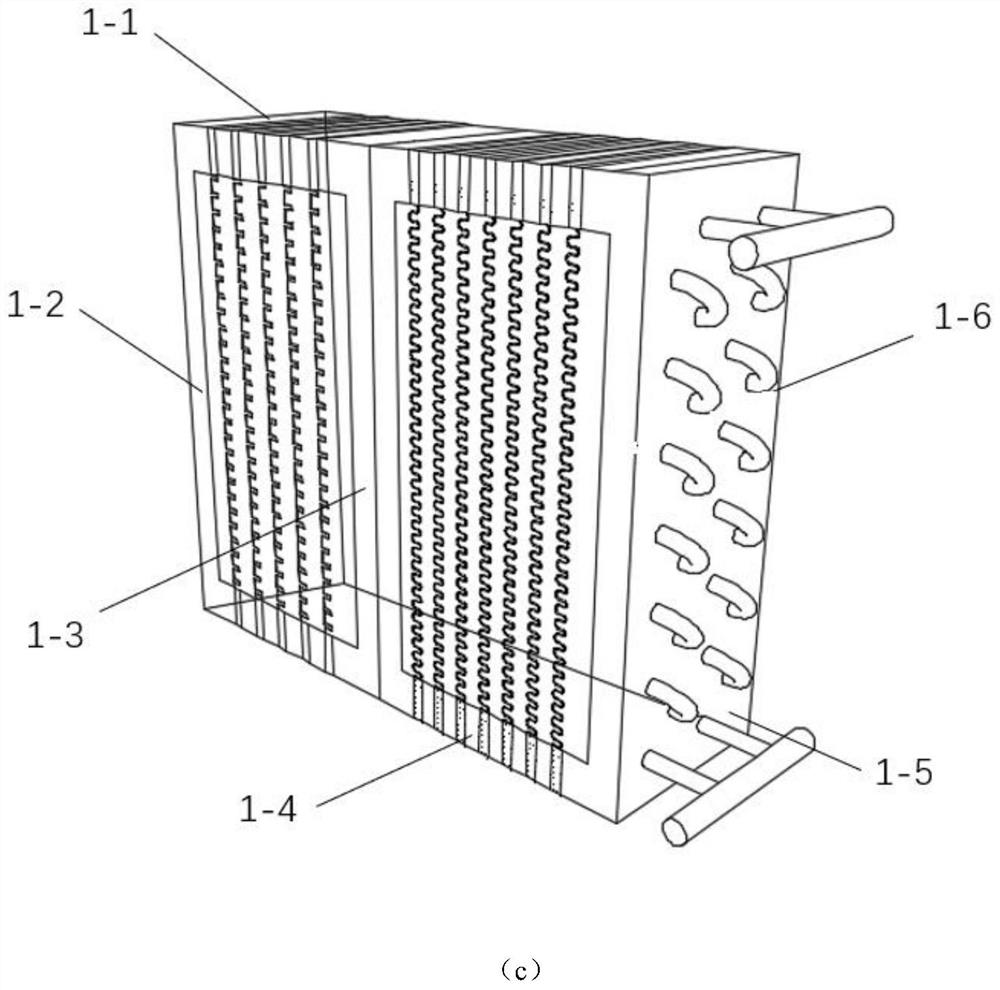

Embodiment 1

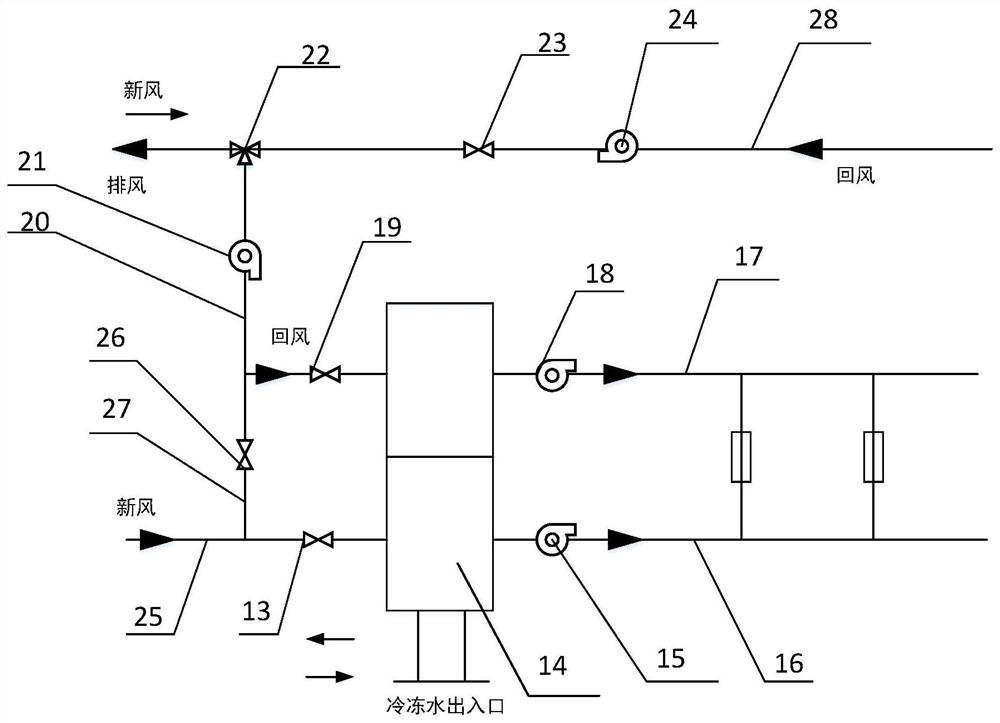

[0091] Take the operating condition of the air conditioning system without increasing the air volume as an example:

[0092] It is known that the fresh air volume to be processed is 1.7kg / s, and the initial air parameter is t 1 = 33.5°C, i 1 =82.63kJ / kg. 干空气 ,t s1 = 24.1°C. And it can be seen that the final air parameter is t 2 =25°C,i 2 =71.28kJ / kg. 干空气 ,t s2 = 23.2°C.

[0093] According to formula (1-2) get ε 2 =0.809, the preliminary selection of the UII type 2-row coil air handling device 14 can meet the requirements. Assume V y is 1.5m / s according to the formula (1-3): Actual A y =0.944

[0094] So bring it into the back calculation to know the actual V y =1.5m / s, consult the relevant manuals to know the ε of the actual 4 rows of UII coil air handling devices 14 2 = 0.841, which is not very different from the required requirements. At the same time, it can be known that the heat transfer area A of each row of the coil air handling device 14 d =12.15m 2 ...

Embodiment 2

[0098] The type selection of the coil air handling device 14 under the fresh air condition is calculated.

[0099] The preset fresh air return ratio is 1:9, and the exhaust air volume is 10%. Under the fresh air operating condition, the total air volume is 5.55kg / s, of which the exhaust air volume is 0.56kg / s. Consistent with the aforementioned embodiment 1, the JW type coil air treatment device 14 is preselected in advance. The initial parameter of air is t 1 = 33.5°C, i 1 =82.63kJ / kg. 干空气 ,t s1 = 24.1°C. And it can be seen that the final air parameter is t 2 =13.4°C, i 2 =41.14kJ / kg. 干空气 ,t s2 = 14.25°C.

[0100] According to formula (1-2) get ε 2 =0.823, the preliminary selection of JW type 8-row coil air treatment device 14 can meet the requirements. Assume V y is 2m / s and can be obtained according to formula (1-3): Actual A y =2.57 So bring it into the inverse calculation to know the actual V y =1.8m / s, refer to relevant manuals to know the ε of the actua...

Embodiment 3

[0104] Assuming the wind speed is 5-6.5m / s, choose the size according to the air volume. The fresh air volume is 1.7kg / s, the total air volume is 5.55kg / s, and the exhaust air volume is 0.56kg / s. According to the "Practical Heating and Air Conditioning Design Manual", the diameter of the fresh air duct is 1250×250, the diameter of the return air duct is 1250×630, and the diameter of the exhaust duct is 320×320. When the pipe length of the exhaust pipe is small, for example, the return air pipe in the machine room directly leads to the outside for exhaust. The pipe diameter of the exhaust air duct and the pipe diameter of the return air duct are selected in accordance with the same. When the pipe length of the exhaust pipe is long, the diameter of the exhaust pipe can be designed according to the way of a large pipe with a small pipe. The diameter of the external pipe is the same as that of the return air pipe, and the built-in air pipe is the same as the original exhaust air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com