Moving-iron type linear motor coil array power-driven allocation method

A technology of linear motors and coil arrays, applied to electrical components, electromechanical devices, electric components, etc., can solve the problem of increasing the number of power drives, achieve the effects of reducing the number of power drives, improving work efficiency, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

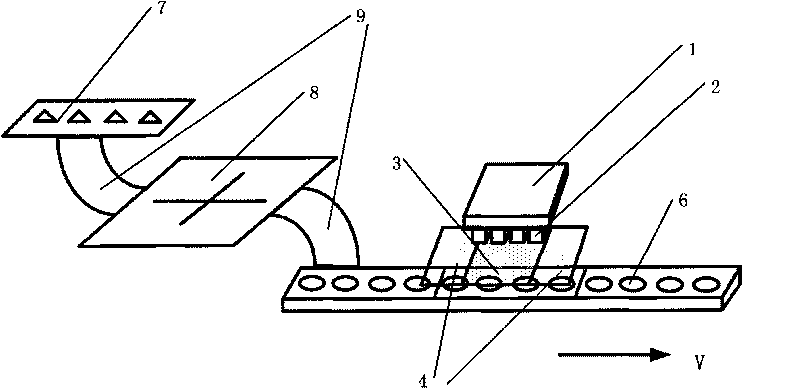

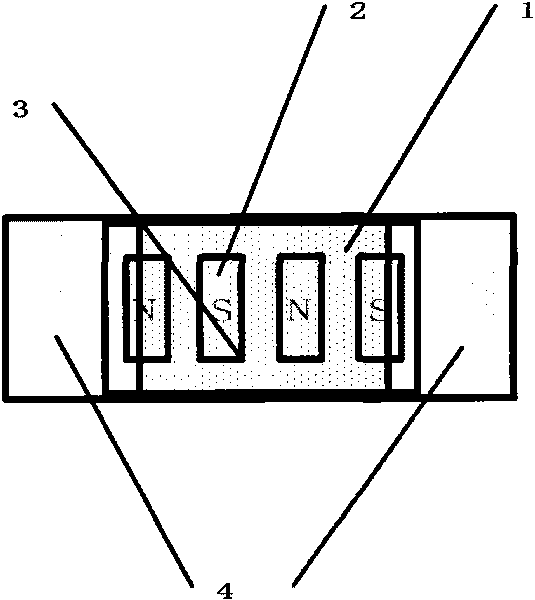

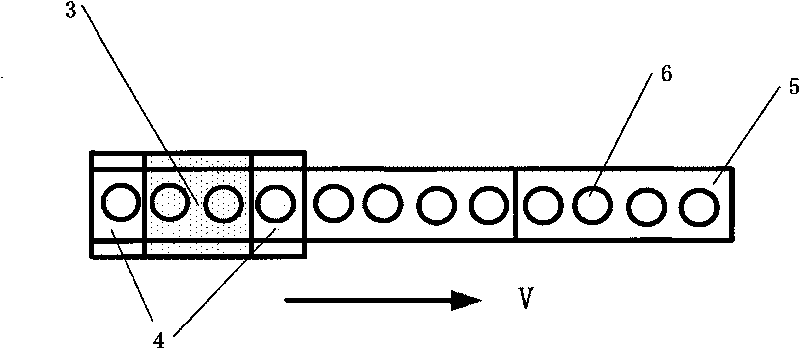

[0045] reference figure 1 4. Demonstrate the transition process of the mover 1 driving the distribution state during the movement, in order to further understand the present invention.

[0046] The maximum speed V of the mover 1 max = 1m / s, the maximum switching time T = 0.1ms for the stator coil array 6 to turn on or off the driver through the switch device 8 = 0.1ms, according to the transition state area 4 width calculation formula L≥V max *T, take L=30mm.

[0047] Under the premise of ensuring that the electromagnetic interaction between the covering coil and the magnetic steel array under the mover magnetic steel array 2 will not produce edge effects, the working state area 3 takes the largest size of the covered coil periphery, that is, the length of the working state area 3 along the direction of movement is 60mm . The inner frame of the transition state area is the same size as the working state area. The inner frame of the transition state area expands the width L of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com