Coffee and dairy liquid concentrates

A concentrate, coffee technology, used in the field of blended coffee and dairy fluid concentrates, to solve the problem of undesired highly concentrated products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

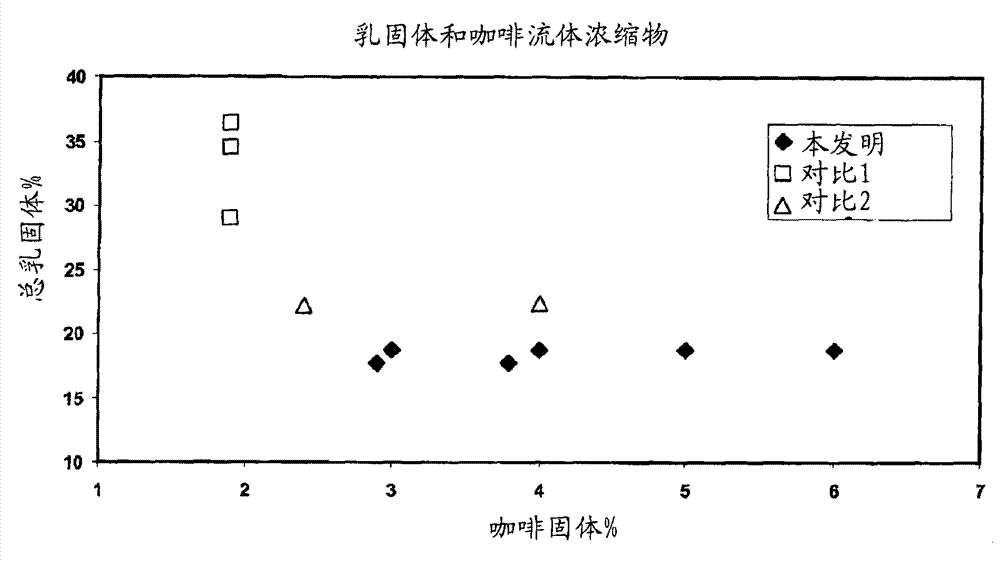

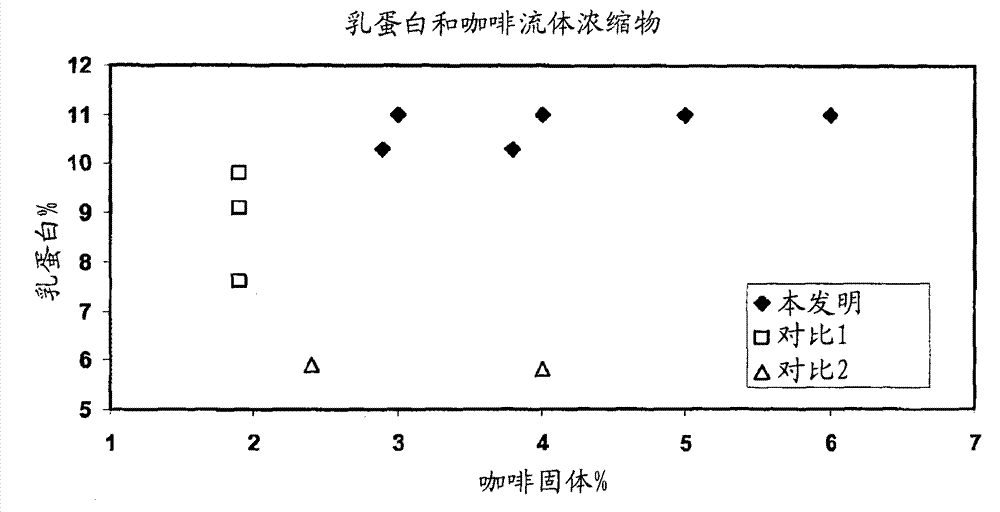

[0053] An analysis was performed to determine total milk solids, total milk protein and total coffee solids that could be incorporated into a liquid milk plus coffee concentrate that remained fluid after heat treatment. The samples tested are listed in Table 1 below and the results of the comparison are provided in the attached figure 1 And attached figure 2 in the figure. attached figure 1 is a graph of the percentage of total milk solids relative to the percentage of coffee solids in the concentrate remaining in a fluid state, with figure 2 is a graph of the percentage of milk protein relative to the percentage of coffee solids in a concentrate that remains in a fluid state. attached figure 1 and 2 Table 1 and the data in Table 1 below illustrate inventive and comparative samples that remained liquid after heat treatment at about 123°C (253°F) and about 30-33 MPa for about 11 minutes.

[0054] Table 1: Samples evaluated (all samples form pourable fluid concentrates) ...

Embodiment 2

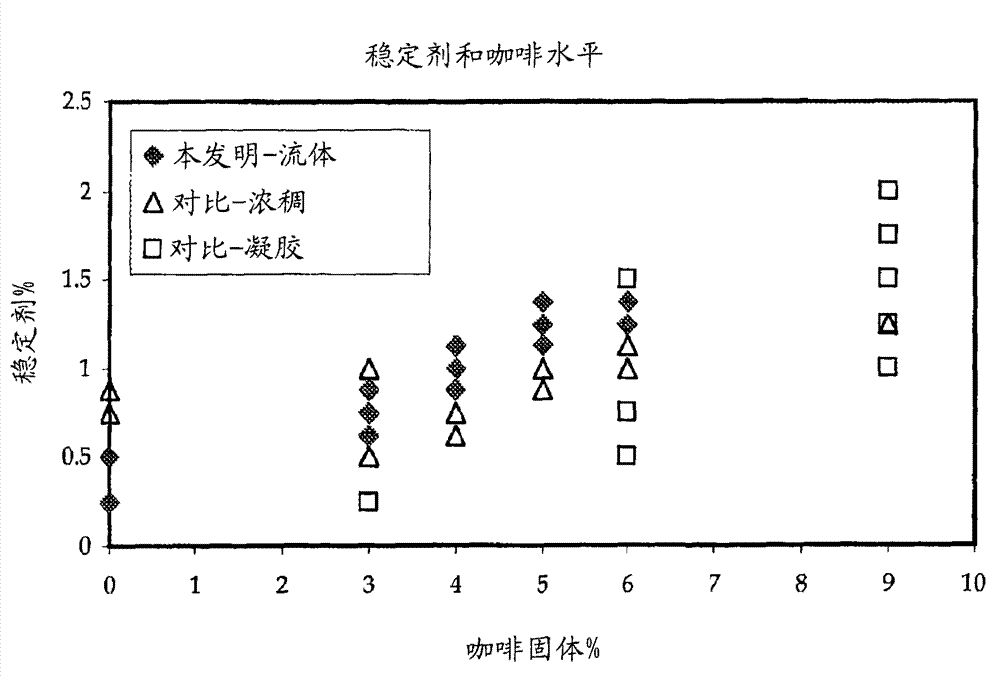

[0061] An analysis was performed to determine the effect of varying the amount of soluble coffee and disodium phosphate level on the texture of the final sterilized concentrate after the samples were heat-treated at 123°C (253°F) and 30-33MPa for 11 minutes. All concentrates in this example consisted of milk that was first prepared by preheating 2% milk at 194°F for 300 seconds, followed by ultrafiltration and diafiltration to approximately 25% solids with less than 1% lactose, and finally The resulting ultrafiltered and diafiltered milk was prepared by homogenizing at 2000 psi. The concentrate of this example further comprises about 7% fat, about 11% milk protein, about 0.6% lactose, about 0.9% sodium chloride, and about 10% sucrose. These samples had a total milk solids content of about 18% such that the concentrate had about 58% milk protein and about 3% lactose by weight of total milk solids, or about 94% milk protein and about 5% lactose by weight of non-fat milk solids ...

Embodiment 3

[0078] Additional comparative experiments were performed to gauge the extent of the acceptable range of coffee to stabilizer ratio by observing what level of stabilizer would result in a fluid concentrate free of coffee solids. A concentrate was prepared as in Example 2 but without coffee solids. Disodium phosphate (DSP) levels of 0.25 and 0.5% for decaf solids produced a fluid concentrate, while DSP levels of 0.75, 0.875 and 1.0% produced concentrates that were too thick. These results are also shown in the attached image 3 middle. The result, as in the attached image 3 As shown in , it is expected that the downward trend in the ratio of coffee to stabilizer will be applicable to levels below 3% coffee determined in Example 2, so that when containing about 2% coffee solids, the expected effective ratio in the fluid concentrate will be In the range of about 5.8:1 to about 3.3:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com