Process for repairing inner surface damages in outer cylinder and inner cylinder of mine hydraulic support column

A hydraulic support column and inner surface technology is applied in the field of repair technology for damage to the inner surface of an outer cylinder and a middle cylinder of a hydraulic support column for mines, which can solve the problem that the inner surface of the cylinder is not easy to repair, and achieves a reliable and easy repair process. Stable product quality and considerable economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

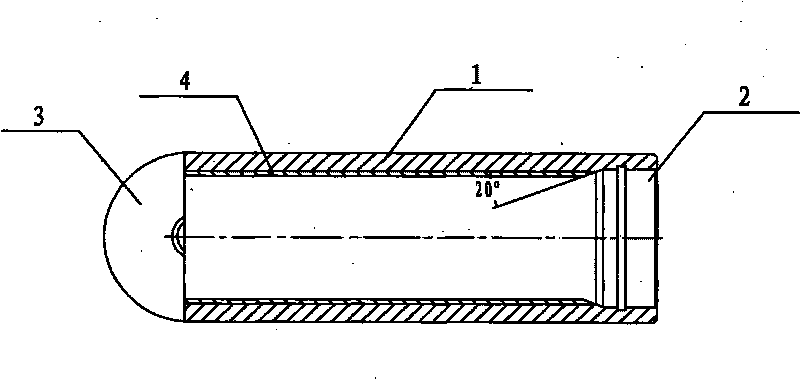

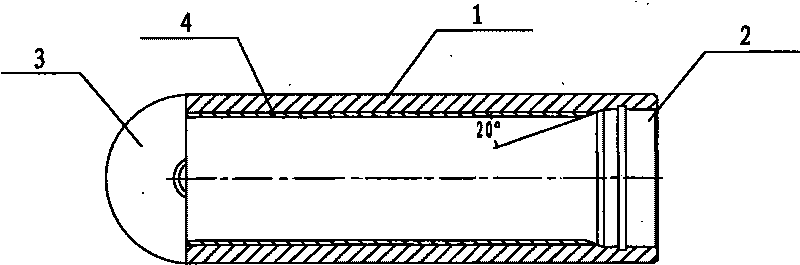

[0016] Referring to the accompanying drawings, the inner diameter is Take the outer cylinder as an example to illustrate the specific implementation process:

[0017] a. Turn off the cylinder bottom 3 of the cylinder barrel 1 on a lathe, and grind off the joints and oil pipes;

[0018] b. Put on the lathe, turn both ends of the cylinder 1 flat, pour the outer angle of 15°, and repair the frame opening;

[0019] c. Locate with the 15° outer chamfer of the cylinder port 2, and bore the inner hole to Ensure the concentricity requirements of the cylinder port 2 and the boring port;

[0020] d. Use a high-frequency heating furnace to bore the inner hole of the cylinder barrel 1 and prepare the cylinder inserting part and heat it to 580 ° C ~ 620 ° C;

[0021] e. Put the cylinder 1 out of the furnace on the disc tooling on the platform, quickly press the stainless steel cylinder 4 into the inner hole of the cylinder 1 with a spinning machine, and spin at the same time, the oute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com