Connecting rod-ball valve type hydraulic damping device for vehicle

A vibration damping device and ball valve technology, which is applied to vehicle parts, transportation and packaging, elastic suspension, etc., can solve the problems of easy deformation of the valve plate, unstable work, high production cost, etc., so as to avoid blockage of the main oil hole and improve work efficiency. Reliability and life extension effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

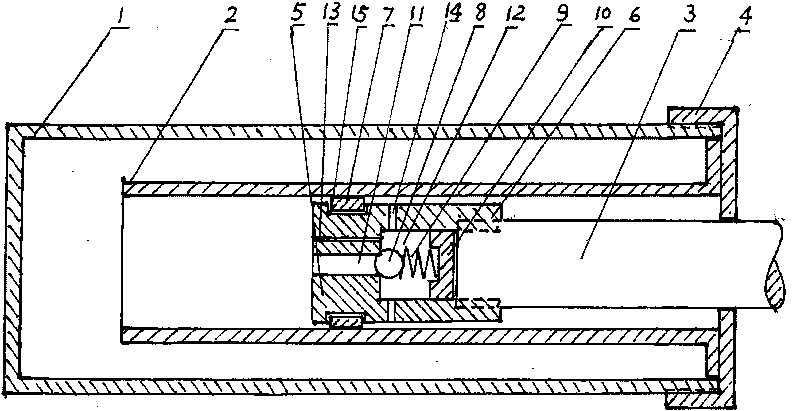

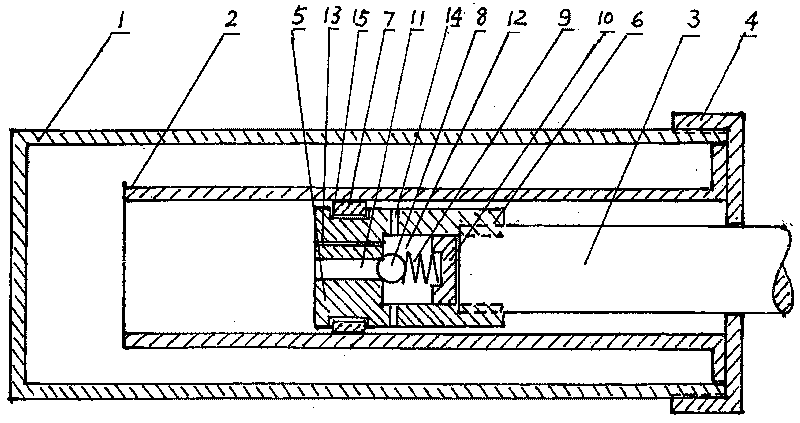

[0009] The specific embodiment includes an outer cylinder 1, an inner cylinder 2, a piston connecting rod 3, an outer cylinder end cap 4 and a throttle valve 5; The outer cylinder 1 is removed, and there is a piston connecting rod hole in the center of the outer cylinder end cover 4, and the piston connecting rod 3 can move in the piston connecting rod hole; the left end of the inner cylinder 2 is open, and the inner cylinder 2 is installed in the outer cylinder 1, and the inner cylinder The right end of 2 is installed on the end cover 4 of the outer cylinder, and the damping fluid is contained between the outer cylinder 1 and the inner cylinder 2; the throttle valve 5 includes a valve body 6, a piston ring 7, a ball valve core 8, a spring 9 and a spring seat 10, and the valve The outer diameter of the body 6 is slightly smaller than the inner diameter of the inner cylinder 2, and the valve body 6 has a second-stage hole, the left section of the second-stage hole is the main oi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com