Fluid pump with an integrated mounting interface

A fluid pump, installation structure technology, applied in the parts, pump components, transportation and packaging of the pumping device for elastic fluid, can solve the problem of improper installation of fluid pump, heavy equipment and tools, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following detailed description and drawings describe and illustrate various exemplary embodiments of the invention. This description and drawings serve to enable those skilled in the art to make and use the invention and are not intended to limit the scope of the invention in any way.

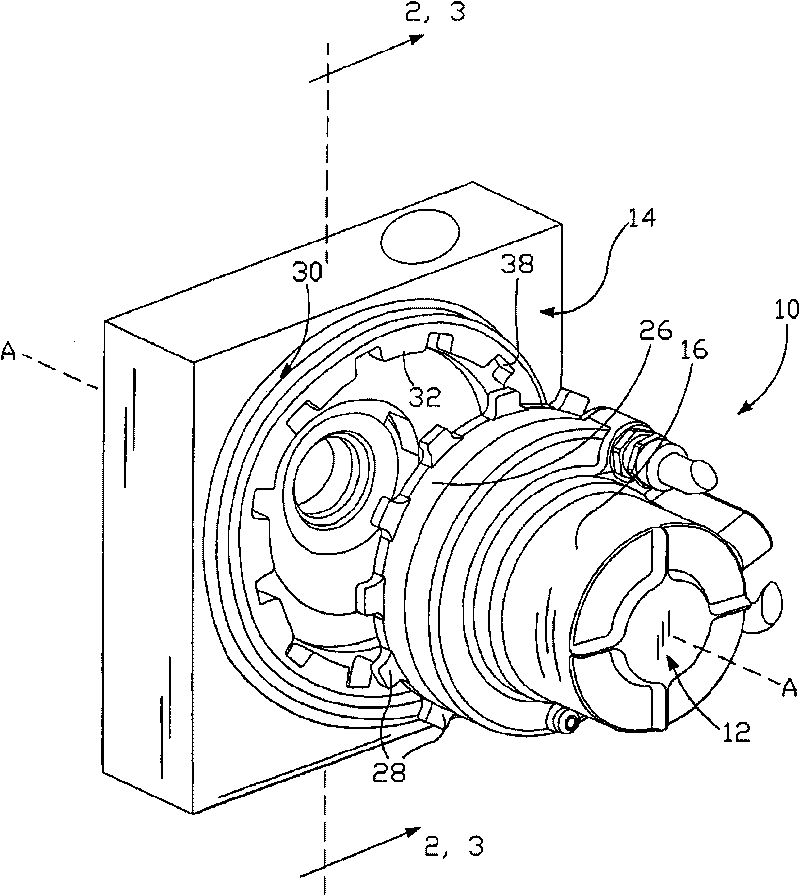

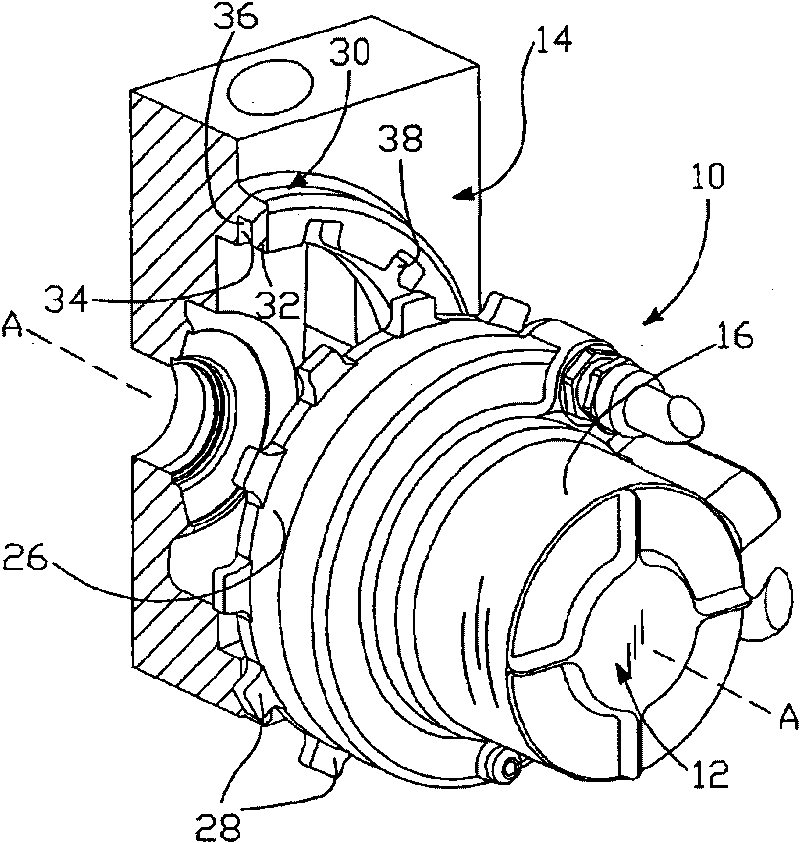

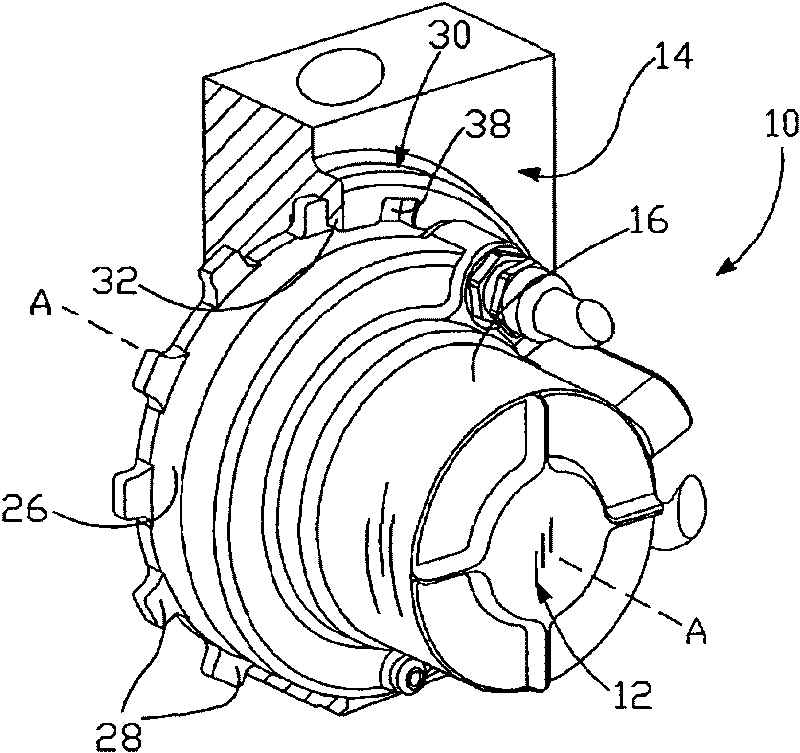

[0022] figure 1 A fluid pump assembly 10 is shown in accordance with an embodiment of the invention. The fluid pump assembly 10 includes a fluid pump 12 and a corresponding mounting structure 14 . It should be understood that the fluid pump 12 may be any type of fluid pump as required, such as a flexible impeller pump, a piston pump, a rotary vane pump, and the like. The fluid pump 12 is adapted to cooperate with the mounting structure 14 and to rotate about the axis A from a first position to a second position. The second position is also known as the locked position, as image 3 As shown, a twist-lock connection is formed. It should be understood that the fluid pump 12 can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com