Liquid crystal display panel

A liquid crystal display panel and liquid crystal layer technology, which is applied to static indicators, optics, instruments, etc., can solve problems such as brightness changes of liquid crystal display panels 1, afterimages of liquid crystal molecules on liquid crystal display panels 1, flickering of display panels 1, etc., and achieve improvement Brightness and color deviation, the effect of improving quality and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The liquid crystal display panel and its pixel structure according to preferred embodiments of the present invention will be described below with reference to related figures.

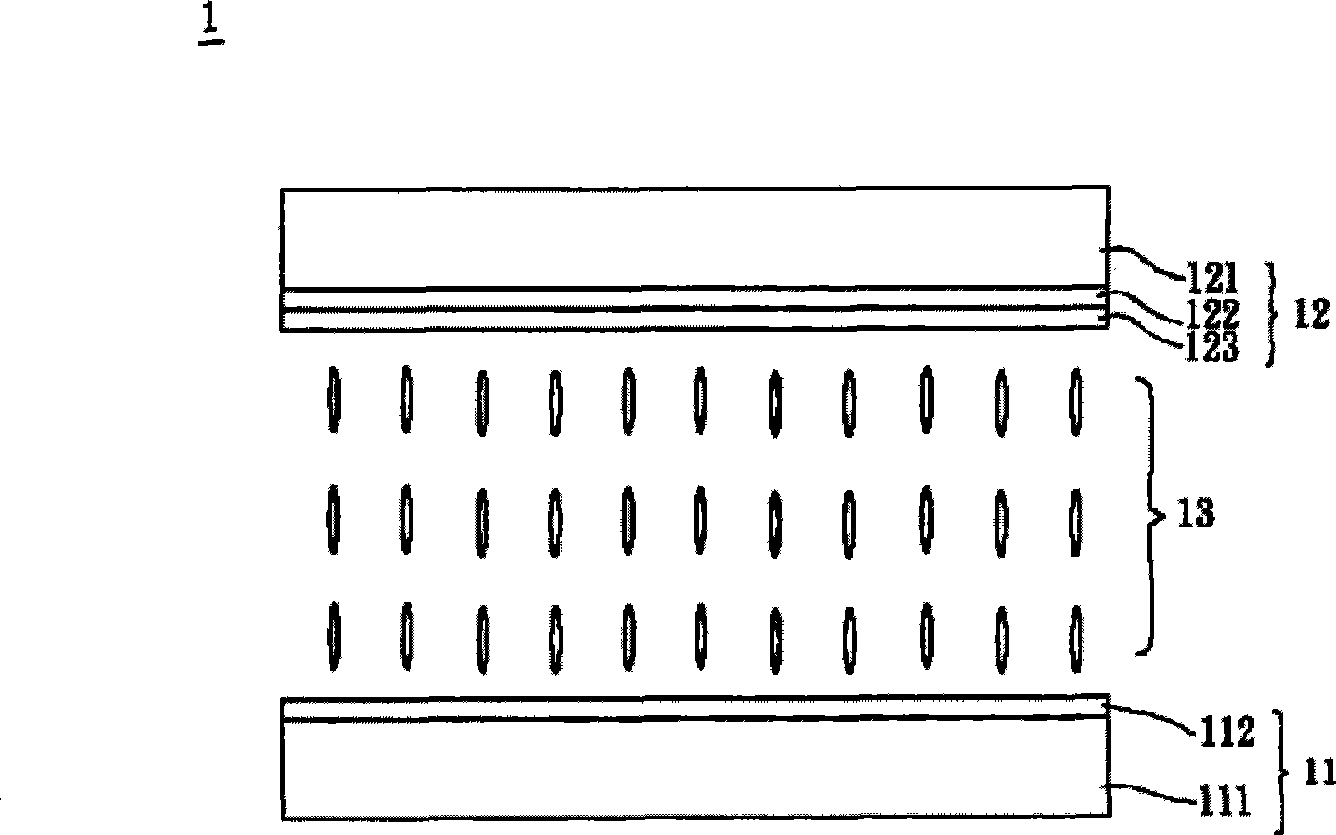

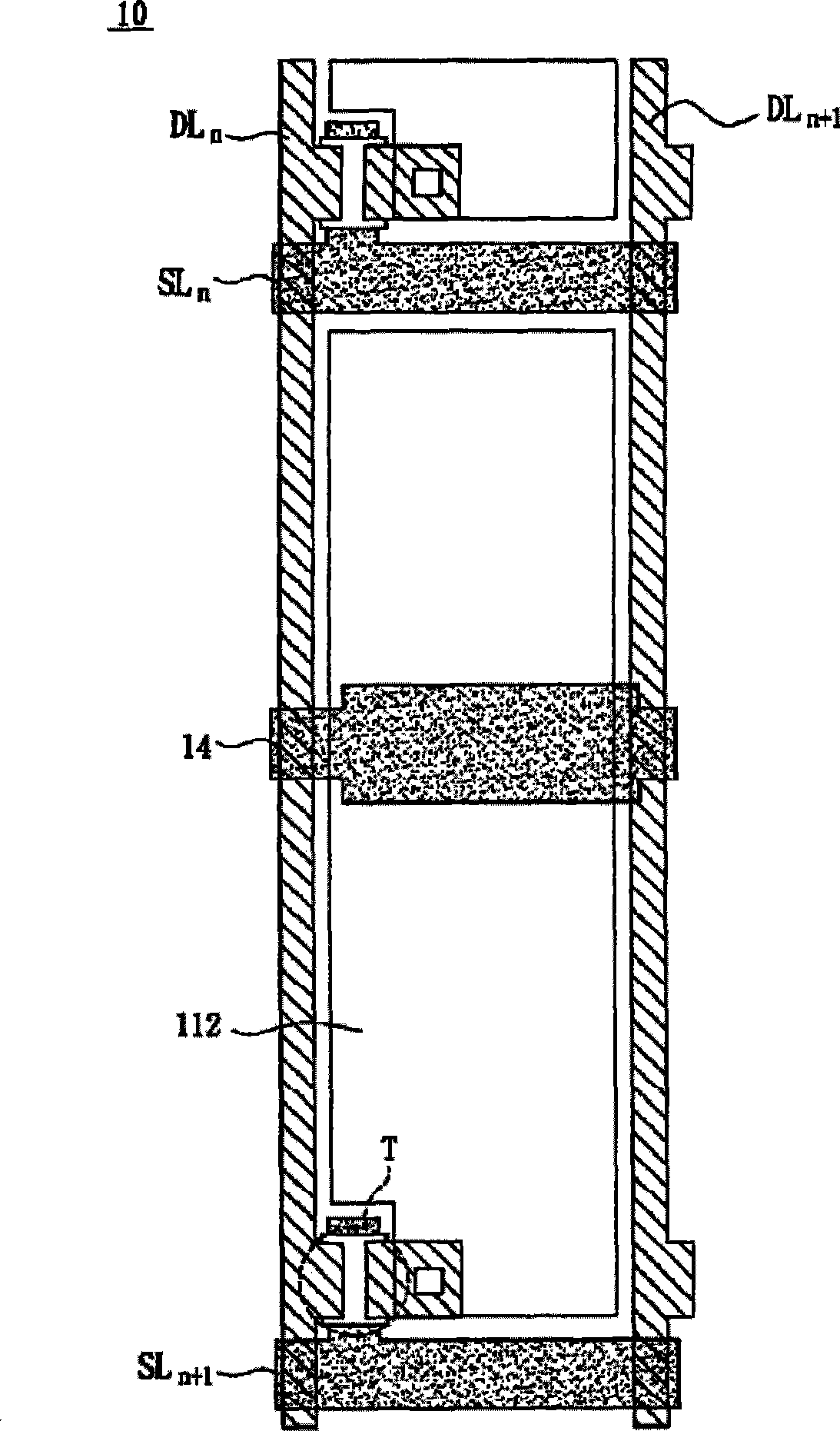

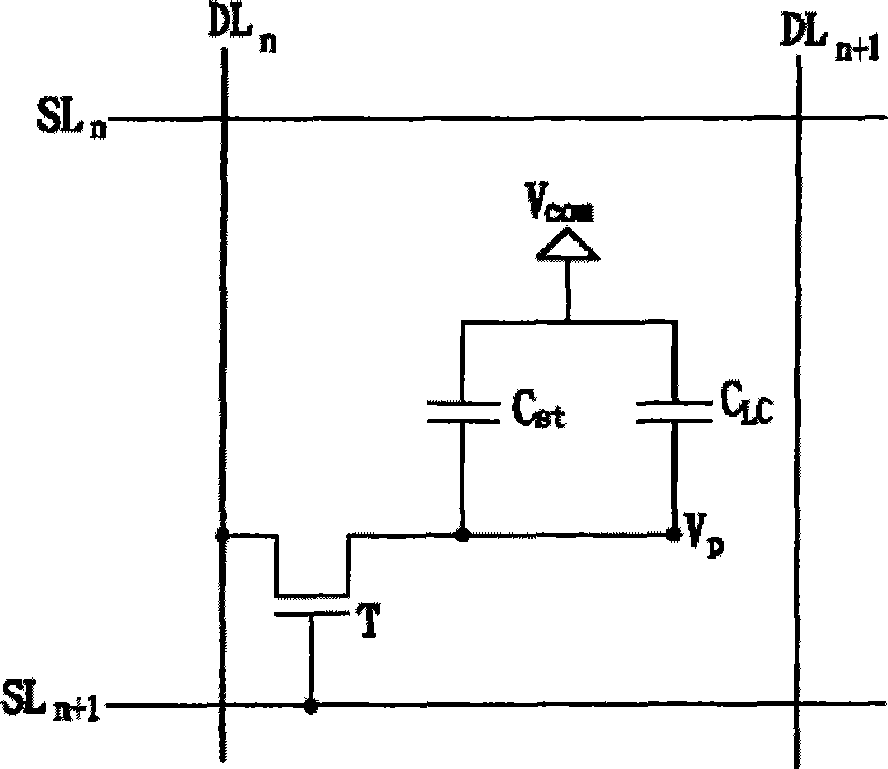

[0062] Please refer to Figure 5 As shown, it is a schematic cross-sectional view of a liquid crystal display panel 2 according to a preferred embodiment of the present invention. The liquid crystal display panel 2 includes a first substrate 21 , a second substrate 22 , a liquid crystal layer 23 and a multi-pixel structure (not shown in the figure). The first substrate 21 is disposed opposite to the second substrate 22 , and the liquid crystal layer 23 is disposed between the first substrate 21 and the second substrate 22 . Wherein, these pixel structures are arranged in a matrix, and each pixel structure is arranged between two adjacent data lines and two adjacent scan lines. In addition, the liquid crystal display panel 2 can be a twisted nematic (TN) type liquid crystal display panel, a mul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com