Galling device for prestressed anchor recess of rail slab

A technology for roughening devices and railway tracks, which is applied to ceramic forming machines, manufacturing tools, ceramic forming cores, etc., can solve the problems of easily damaged track plates, time-consuming, labor-intensive, and low efficiency, and achieve material saving, work load reduction, and regular traces Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

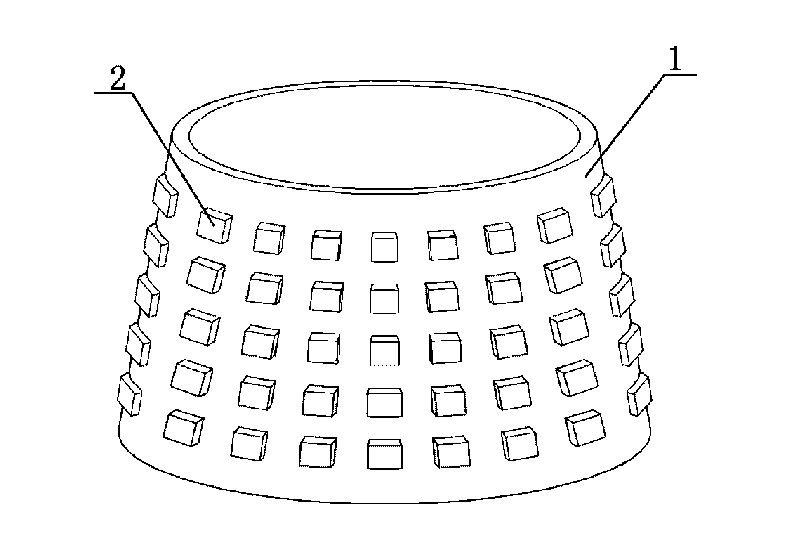

[0024] Embodiment one sees figure 1 As shown, this railway track slab prestressed anchor hole roughening device is a rubber sleeve 1 set on the anchor hole forming device, and the outer surface of the rubber sleeve 1 is distributed with regularly arranged dot-shaped protrusions. The rubber sleeve 1 is in the shape of a circular platform, and the protruding body is a rectangular bump 2 . The specifications and dimensions of the napping device can be designed as follows: the thickness of the rubber sleeve 1 is 10mm; the height of the rubber sleeve 1: 60mm; the outer diameter of the top surface of the round table: 70mm; 7 mm, the spacing is 10 mm.

Embodiment 2

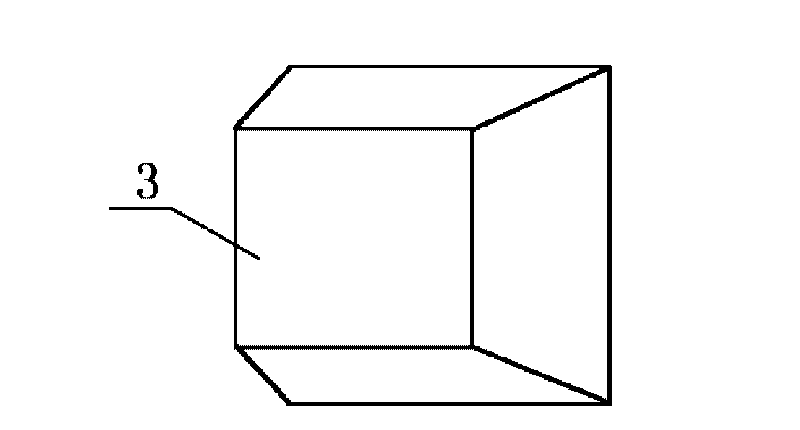

[0025] Embodiment two see figure 2 As shown, different from the first embodiment, the protruding body can also be a prism-shaped bump 3 .

Embodiment 3

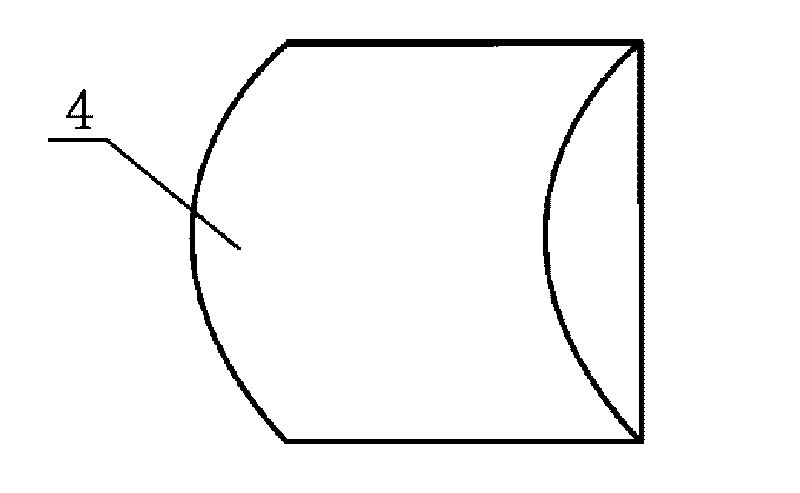

[0026] Embodiment three see image 3 As shown, different from the first embodiment, the protruding body can also be a semi-cylindrical bump 4 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average width | aaaaa | aaaaa |

| Spacing | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com