Dust-proof structure of tool station

A dust-proof structure and machine tool technology, applied in the direction of manufacturing tools, work accessories, stone processing equipment, etc., can solve problems such as low dust collection efficiency, and achieve the effect of avoiding outward spread.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to illustrate the central idea of the present invention expressed in the column of the above-mentioned content of the invention, it is expressed in specific embodiments. Various objects in the embodiments are drawn according to the proportions, sizes, deformations or displacements that are suitable for description, rather than drawn according to the proportions of actual components, which will be described first. And in the following description, similar components are denoted by the same numerals.

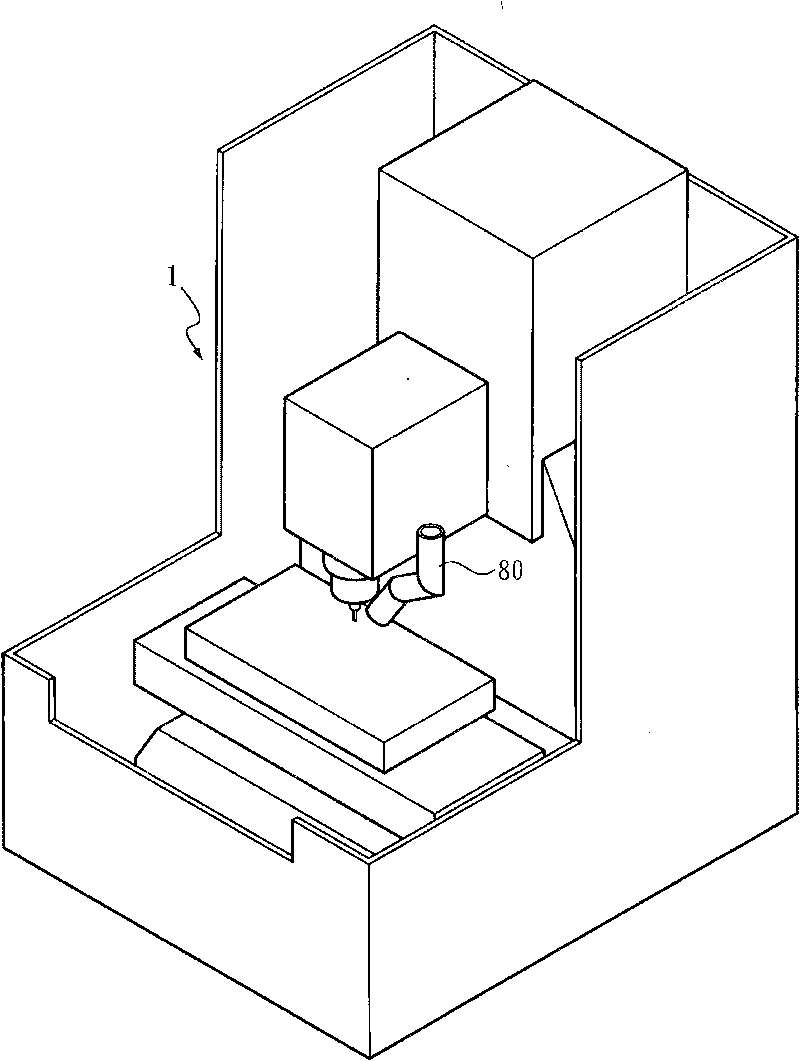

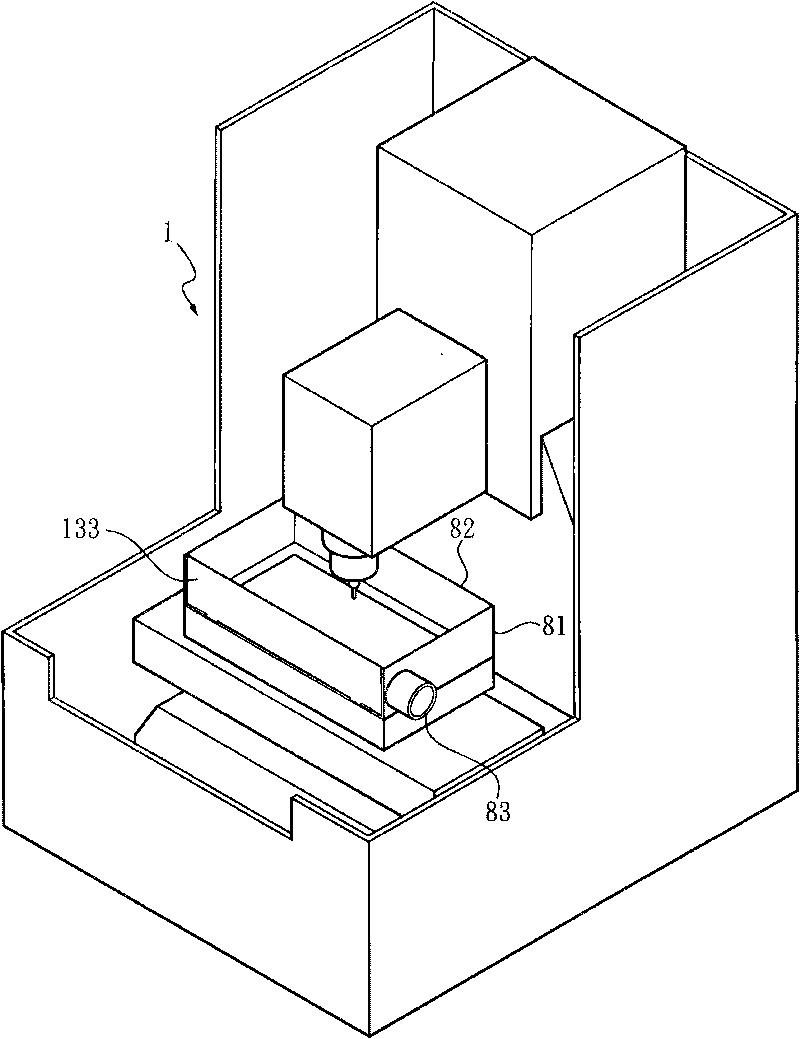

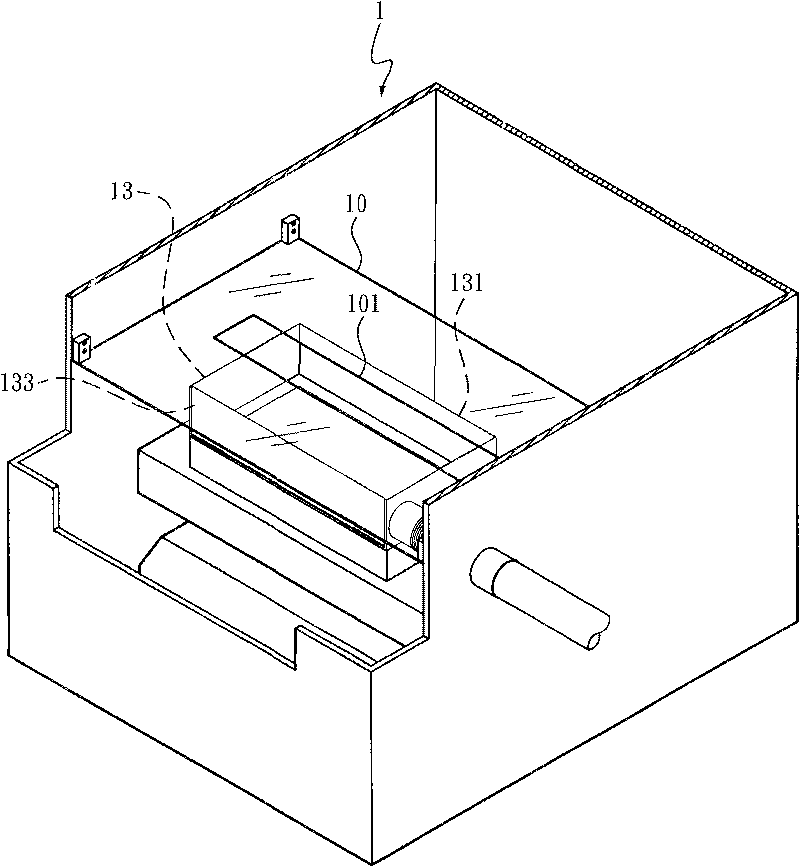

[0034] Refer to the present invention Figure 3 to Figure 5 As shown, a dust-proof structure of a machine tool, including: a dust cover 3 arranged on the machine table 1 of a machine tool, the dust cover 3 has an upper air intake structure and a lower air extraction structure , the dust cover further includes an anti-dust plate 10 having a spindle hole 101 above which the spindle 21 of the machine 1 freely passes up and down, and the spindle hole 101 adopts a lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com