Braking mechanism of rotary drawing and blowing machine

A braking mechanism and stretch blowing machine technology, which is applied in the field of braking mechanisms and plastic hollow container stretch blow molding machines, can solve the problems that the rotating spindle cannot be reliably stopped, the cylinder and the rotating spindle are easily damaged, and the brake pads are easy to fail. Achieve the effect of avoiding damage to the rotating spindle, low maintenance rate, and good braking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

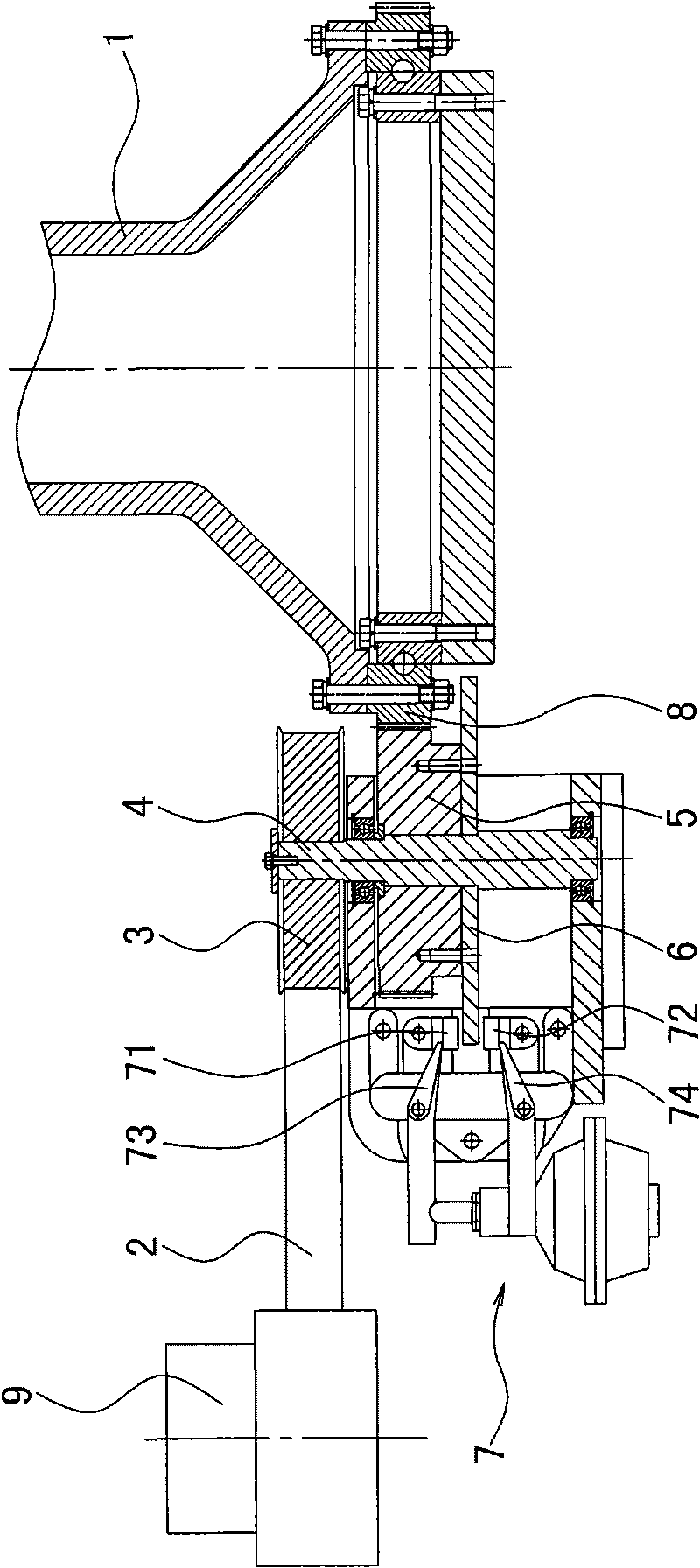

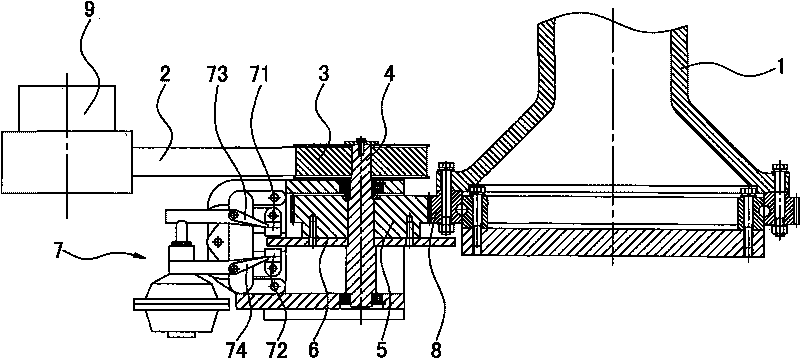

[0008] The invention discloses a braking mechanism of a rotary stretch-blow machine. The rotary stretch-blow machine includes a feeding mechanism, a heating device, a stretch-blow mechanism and a bottle fetching mechanism. The stretch-blow mechanism includes a stretch mechanism, a blow mechanism and an opening mechanism. The mold clamping mechanism and the stretching and blowing mechanism are driven by the rotating spindle to rotate in the circumferential direction, and the rotating spindle is driven by the motor, such as figure 1 As shown, it is characterized in that a driven gear 8 is installed on the bottom of the rotating main shaft 1, and the motor 9 is connected to the transmission shaft 4 through the synchronous belt 2 and the synchronous pulley 3, and the transmission shaft 4 is externally fixed to the driving gear 5, and the driving gear 5 is meshed with the driven gear 8, the driving gear 5 is fixedly connected to the brake disc 6, and the top surface and the bottom s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com