Cellulose hydrolytic enzyme beta-1,4 glucose incision enzyme gene

An endoglucanase and cellulose technology, applied in genetic engineering, plant genetic improvement, enzymes, etc., can solve problems such as environmental pollution, loss of organic matter components, and damage to soil physical and chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

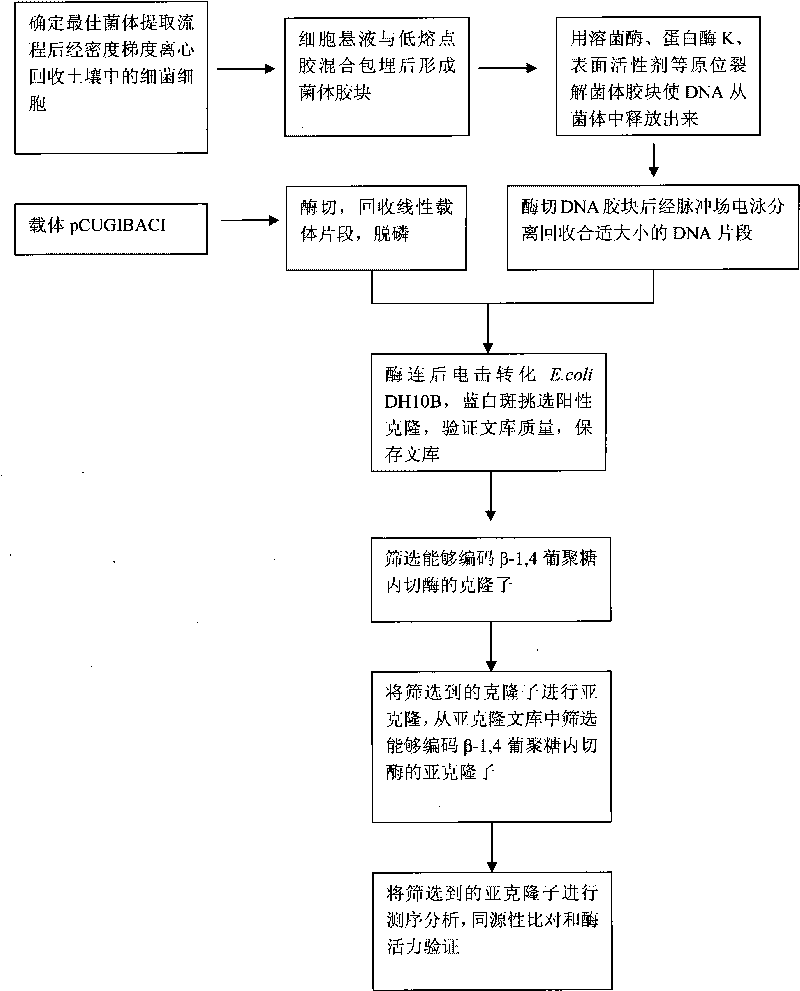

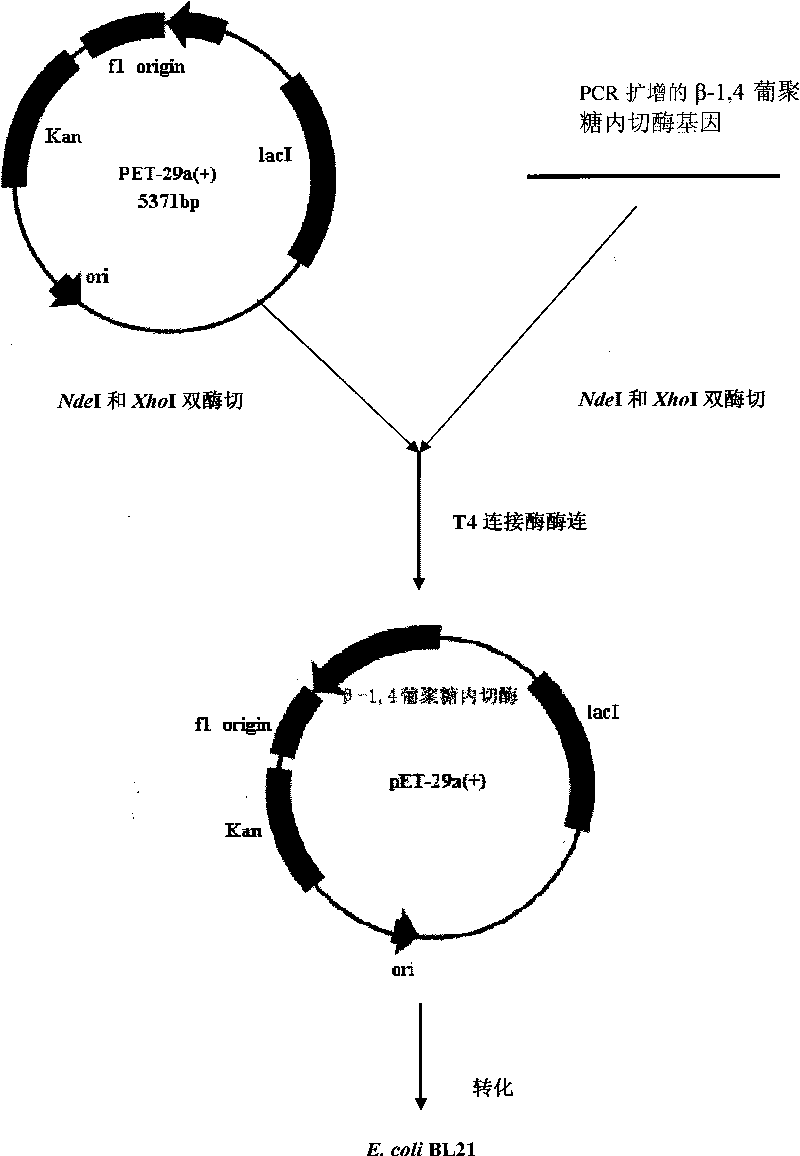

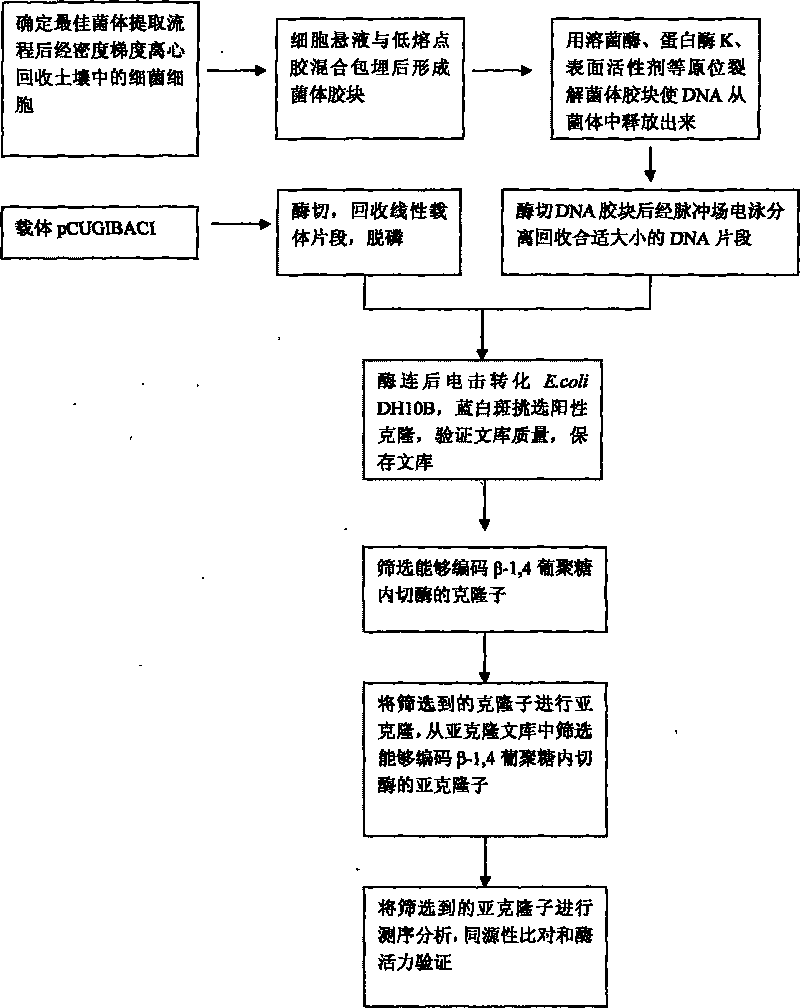

[0021] 1. Cloning of β-1,4 endoglucanase gene

[0022] 1.1 Construction of functional genome BAC library of red soil microorganisms

[0023] Use 0.2% sodium pyrophosphate aqueous solution as a dispersant to suspend soil particles with a water-to-soil ratio of 3:1, and homogenate as a dispersion method (Joyoung JYL-350, 22,000rpm, 3s, 12 times) to release the bacterial cells from the soil particles, After preliminary separation of bacteria and soil particles by sucrose density gradient centrifugation, the microorganisms (most bacteria and some fungi and actinomycetes spores) were purified by density gradient centrifugation using Nycodenz (Axis-Shield, Norway) as the medium to obtain The bacterial cells were embedded and lysed with low-melting point agarose (BBI) to obtain large fragments of DNA over 400kb in size, partially digested with restriction endonuclease Sau3AI, and then separated by alternating pulse field electrophoresis (BIO-RAD) and electroelution to collect DNA fr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap