Upper roller supporting and pressurizing arm of drafting device

A technology of drafting device and adjusting device, which is applied in the direction of drafting equipment, textiles, papermaking, spinning machines, etc., can solve the problems such as the negative influence of processing accuracy on parallel maintenance, the influence of slider accuracy, and the change of processing accuracy, so as to reduce the Installation costs, simplified manufacturing, effects of reliable parallel guidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

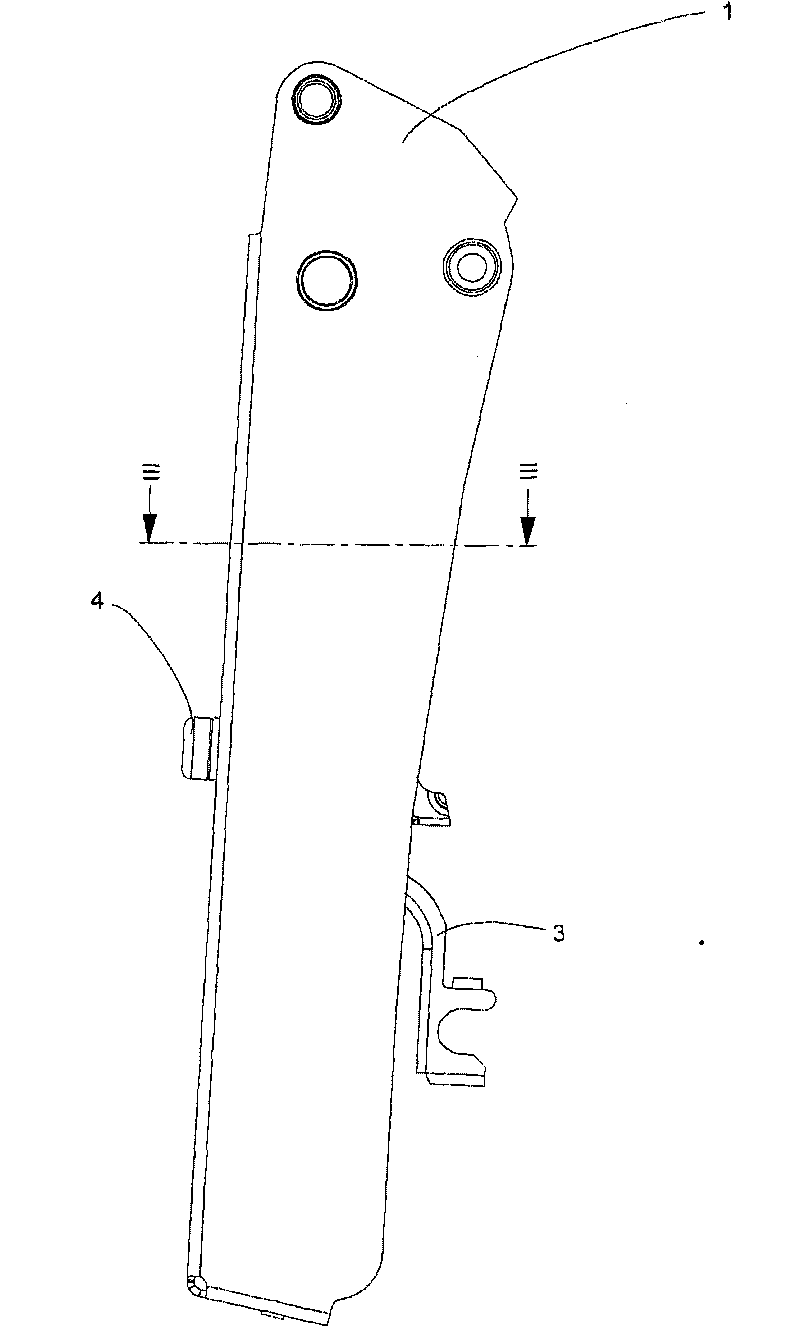

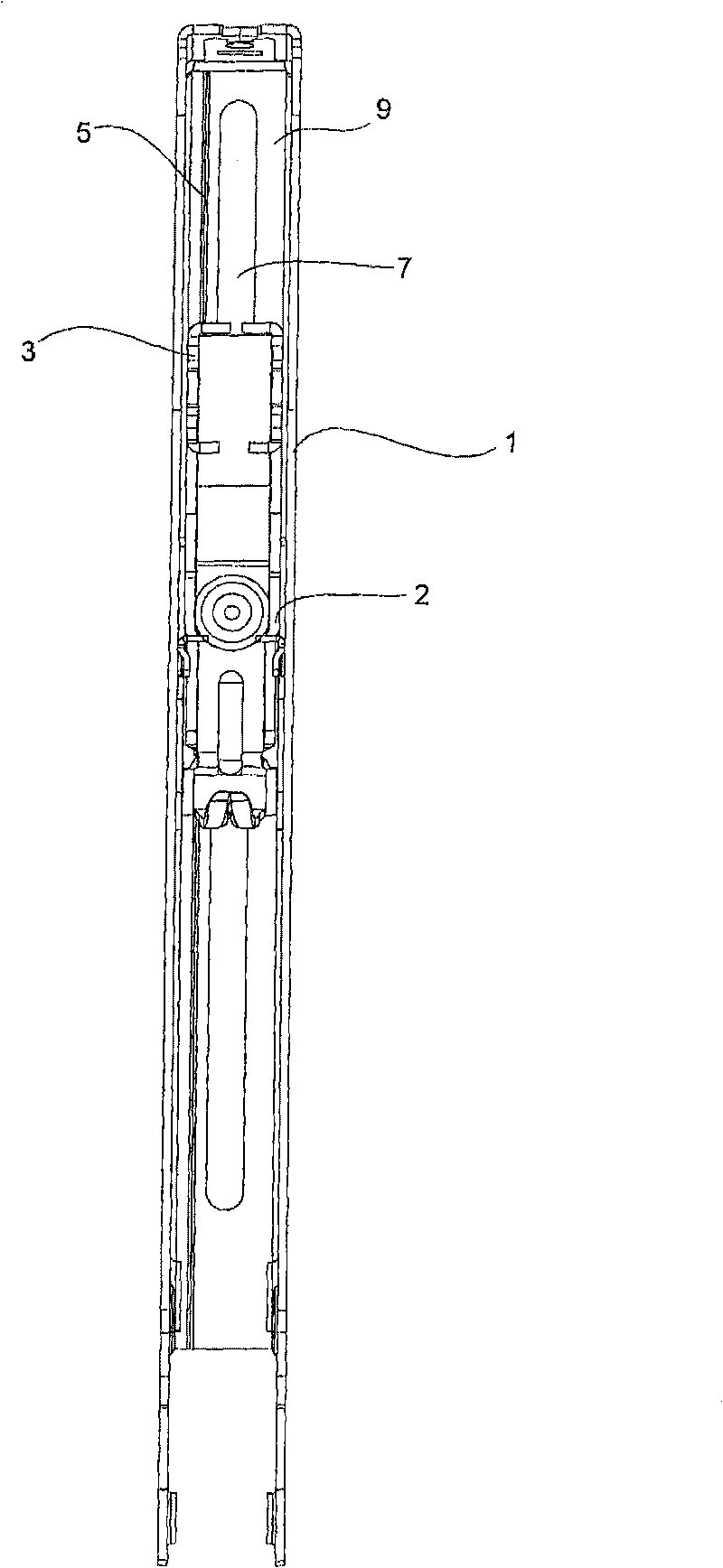

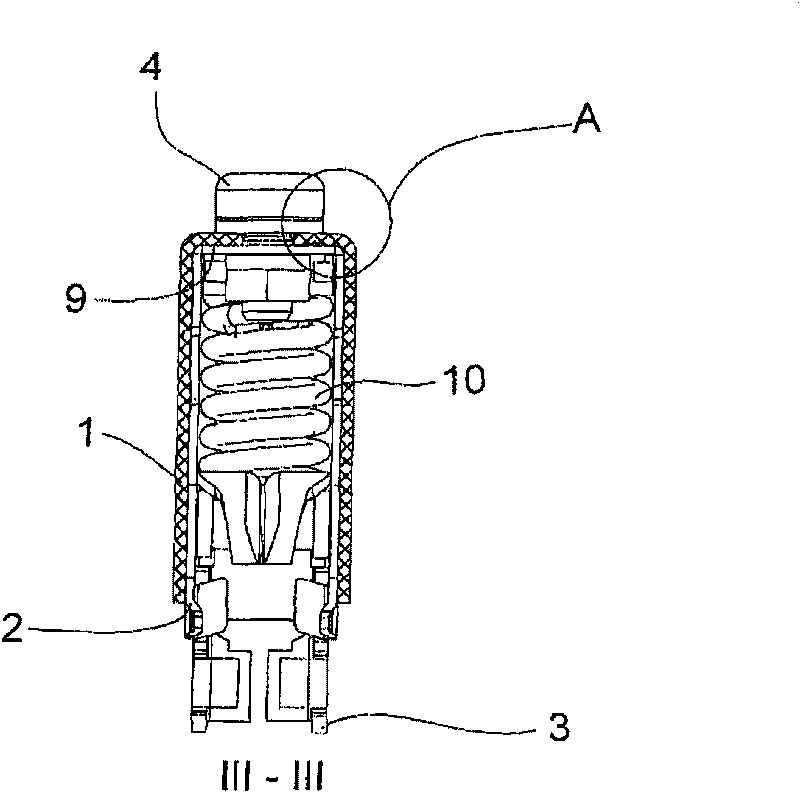

[0044] exist figure 1The view in FIG. 1 shows a bracket 1 for the top roller support and pressure arm of the drafting device of a spinning frame, which is designed as a U-shaped profiled part that is open to the bottom. The carriage 1 is equipped with at least one slide 2 for receiving and loading the top rollers. The slider 2 is fixedly connected with the bracket 1 during the working of the drafting device. It is usually provided that the slide 2 is displaceable in order to adjust the drafting range which is relevant for the function of the drafting device. The movability and fixability of the slider 2 on the carriage 1 is realized by adjusting means 4, such as bolts, in order to fix the slider 2 in a defined position. The slide 2 comprises a pressing element 10 and a grip frame 3 for receiving the top roller.

[0045] In operation, the pressing element 10 applies a pressing force to the upper roller, which is transmitted from the cradle 3 to the upper roller. Furthermore...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com