Upper cylinder carrying and load arm for a stretching unit

A drafting device and top roller technology, which is applied to drafting equipment, textiles, papermaking, spinning machines, etc., can solve problems affecting accuracy, processing accuracy changes, and affecting slider accuracy, etc., to achieve small production costs and simplify manufacturing , the effect of reliable parallel guidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

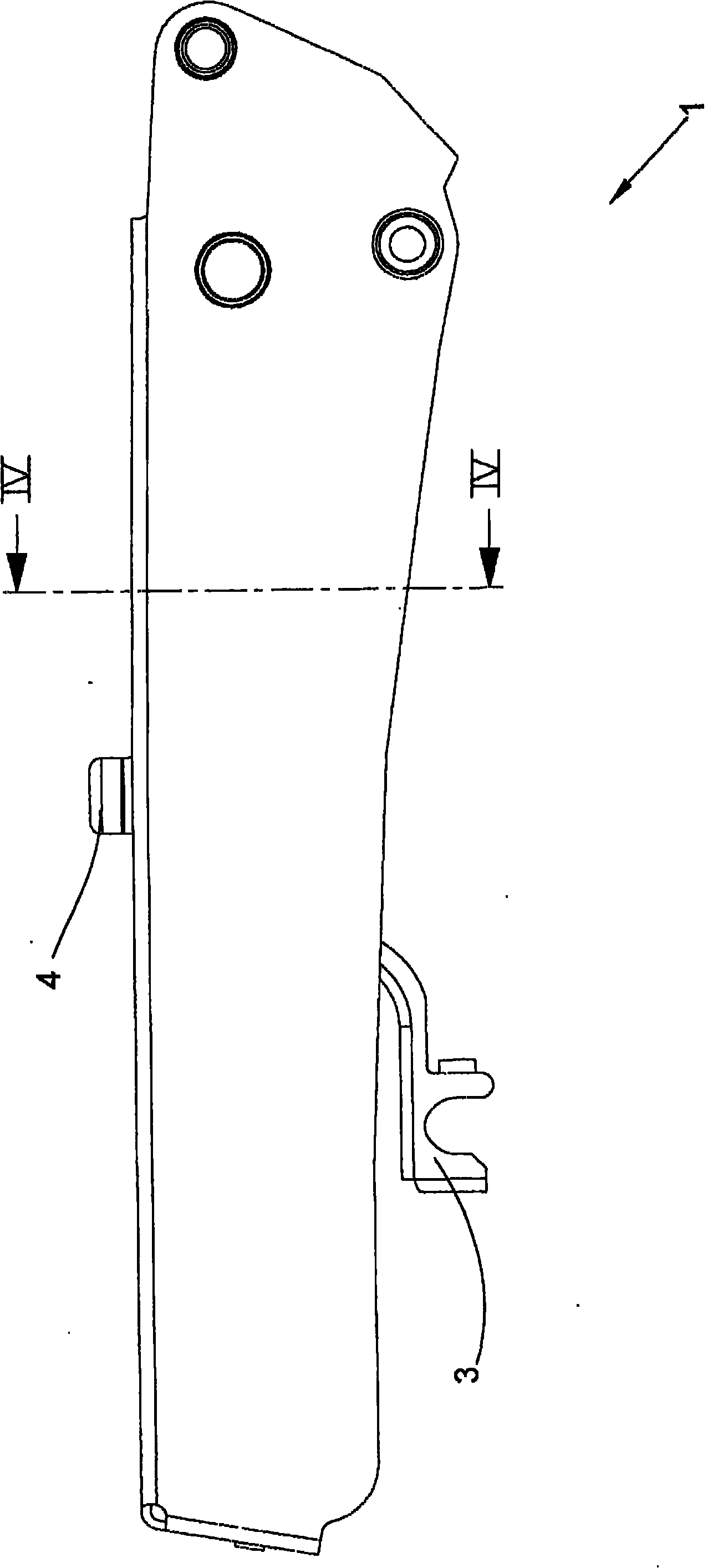

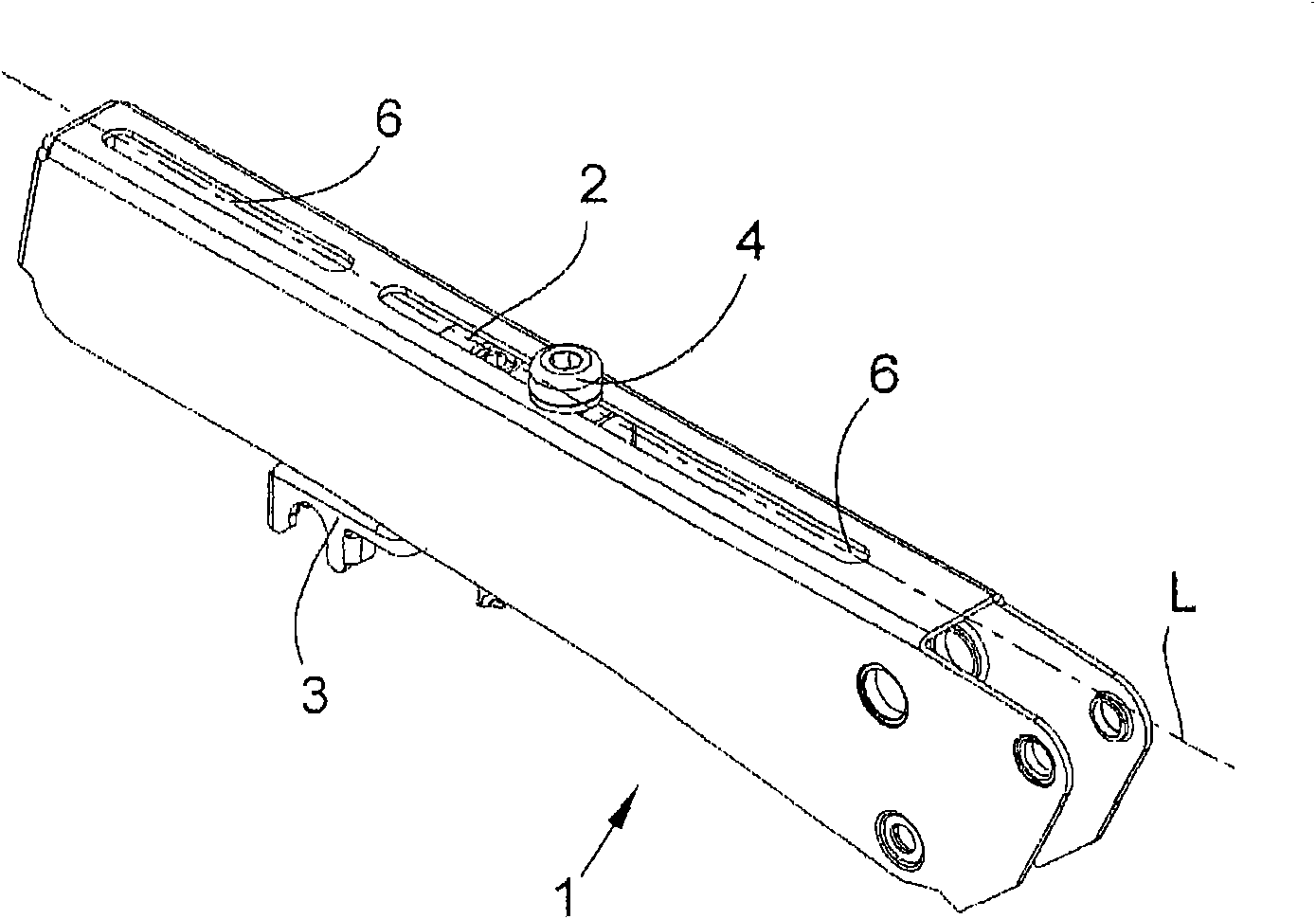

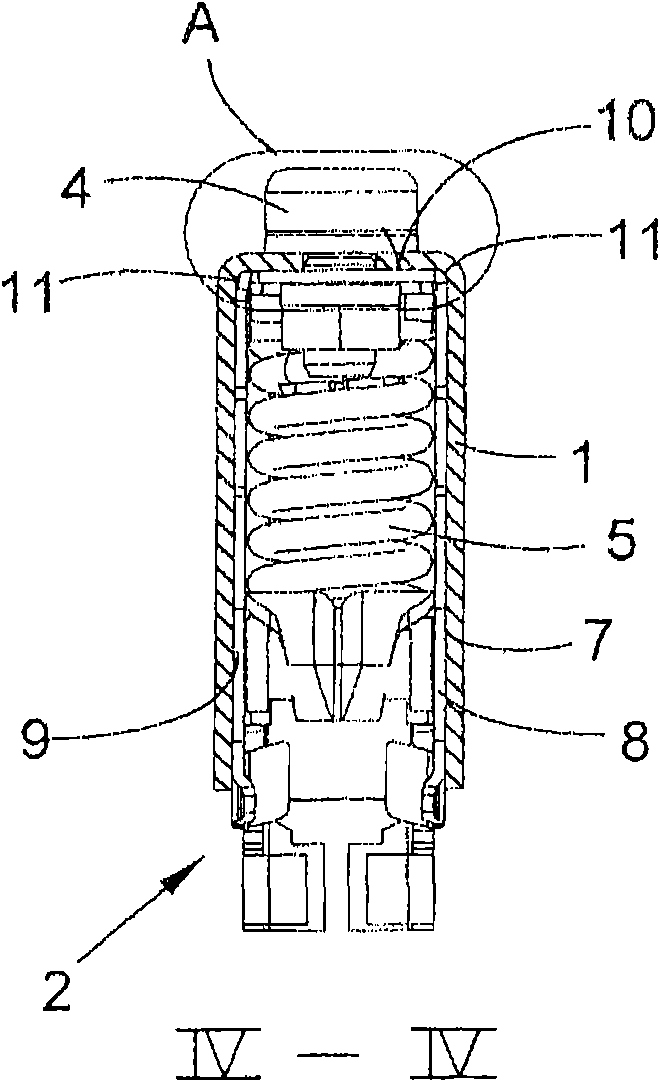

[0038] exist Figure 1 to Figure 6 The view of the drawing shows the bracket 1 for the top roller support and the pressing arm of the drafting device of the spinning frame and at least one preferably U-shaped slider 2 arranged in the bracket 1, the bracket 1 is configured as U-shaped shaped part that opens downwards. The at least one slider 2 is used to accommodate and load the top roller of the drafting device and is fixedly connected to the carriage 1 during the working of the drafting device. It is generally provided that the slide 2 is displaceable along the longitudinal axis L of the carriage 1 in order to adjust the drafting range which is relevant for the function of the drafting device. Such as figure 2 As shown in the illustration of FIG. 1 , the carriage 1 has on its closed upper side recesses 6 configured as elongated holes, within which recesses 6 the slide 2 can be moved so that the drafting range can be adjusted. The movability and fixability of the slider 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com