Ultraviolet resistance yarn and production process thereof

A technology of anti-ultraviolet and production technology, which is applied in the field of wool spinning, can solve the problems of melanin pigmentation, skin aging, deep penetration, etc., and achieve the effect of remarkable effect, soft hand feeling and high strength of chemical fiber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

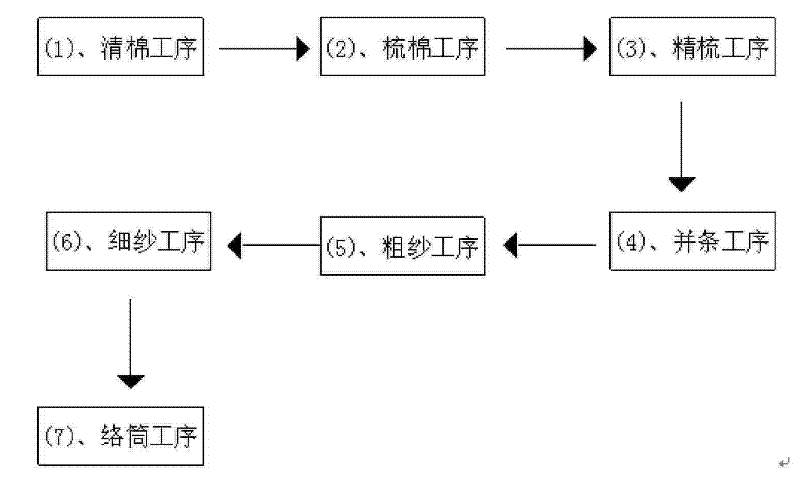

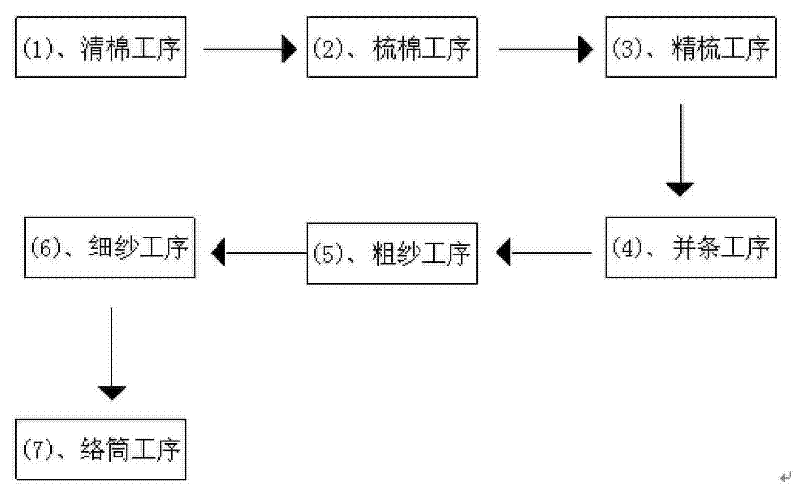

Method used

Image

Examples

Embodiment 1

[0024] Embodiment one. A kind of anti-ultraviolet yarn, when the knitting yarn has a raw weight per kilometer of yarn at a standard moisture regain, it is a knitting yarn with a fineness of 14.6tex, contains 65% of anti-ultraviolet fibers, and 35% of long-staple cotton fibers; The anti-ultraviolet fiber is a nano-anti-ultraviolet fiber made by adding an ultraviolet isolation factor (nano zinc oxide ZnO) during the slicing polymerization process using high-tech nano-spinning technology. The fiber not only reflects ultraviolet radiation, but also strongly selects, absorbs, converts ultraviolet energy into heat energy or other harmless low-energy forms, and releases or consumes it. After being exposed to sunlight, negative ions are produced to promote the decomposition of pollutants such as smoke, ammonia, bacteria and viruses into carbon dioxide and water. It also has heatstroke prevention, heat insulation, heat dissipation before divergence, and cool touch. Keep the cool feel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com