Rolling compaction type ice and snow removing device

A rolling type, ice and snow technology, applied in snow surface cleaning, cleaning methods, construction, etc., can solve the problems of separation of ice and snow from the road surface, low removal rate, damage to the road surface, etc., and achieve compact structure, low cost, and low energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

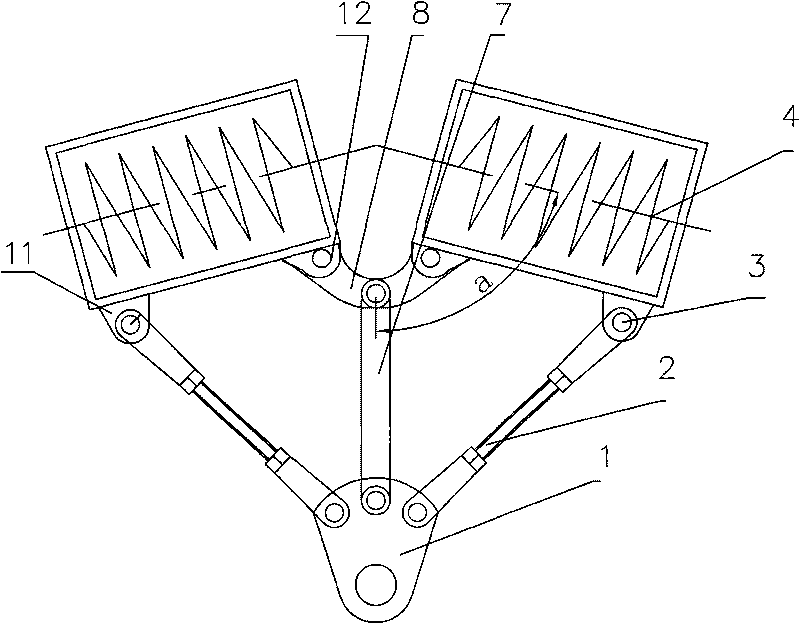

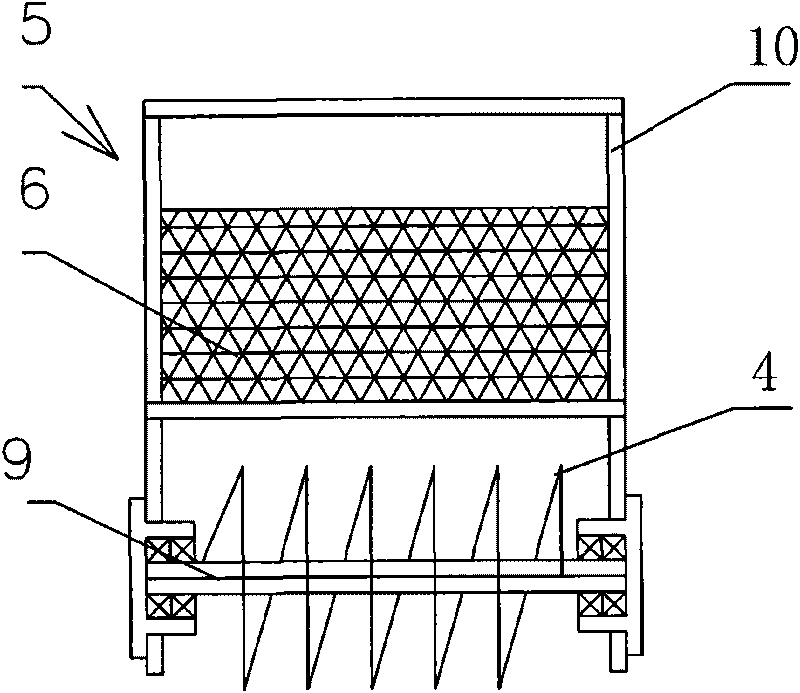

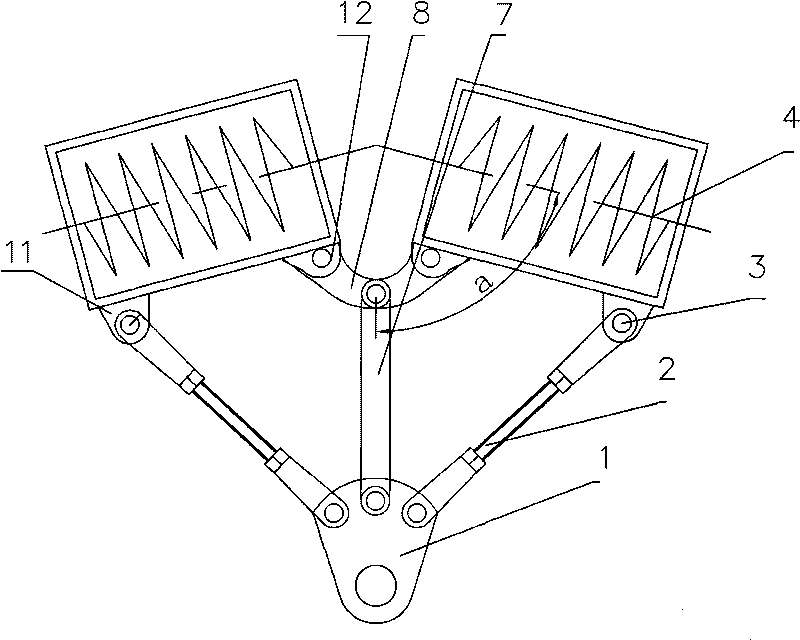

[0019] A rolling rolling type ice and snow removal device, comprising: a traction pan 1, a fixed connecting rod 7, a screw adjusting rod 2, a plurality of connecting pin shafts 3 with the same structure and two rolling cars 5; the two rolling cars 5 includes a casing 10, a counterweight 6, and a spiral rolling wheel 4; the counterweight 6 is installed on the upper part of the casing 10, and the spiral rolling wheel 4 with blade threads is arranged on the outer surface of the casing 10 through the axle 9. bottom. Both sides of the rolling car 5 are respectively provided with connecting lugs 11, and the connecting lugs 11 are provided with connecting pin holes 12. One end of the rolling car 5 is symmetrically and fixedly installed on the two ends of the ear seat 8 respectively. The ear seat 8 is in a bow-shaped structure. The shaft 3 is rotationally connected, the other ends of the two screw adjustment rods 2 are respectively connected to the traction disc 1 through the connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com