Fuel supply device

A fuel supply device and fuel technology, applied in fuel injection devices, liquid fuel feeders, low-pressure fuel injection, etc., can solve the problems of increased components, inability to achieve low cost, complicated piping layout, etc., and achieve simplified piping Layout, component parts reduction, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

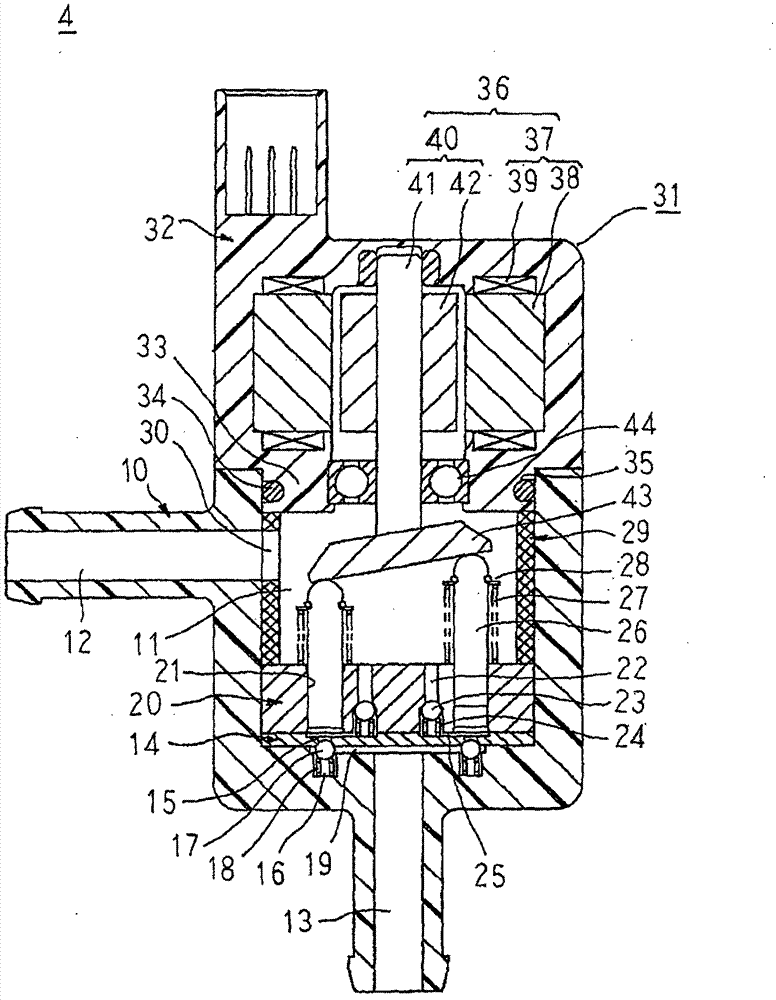

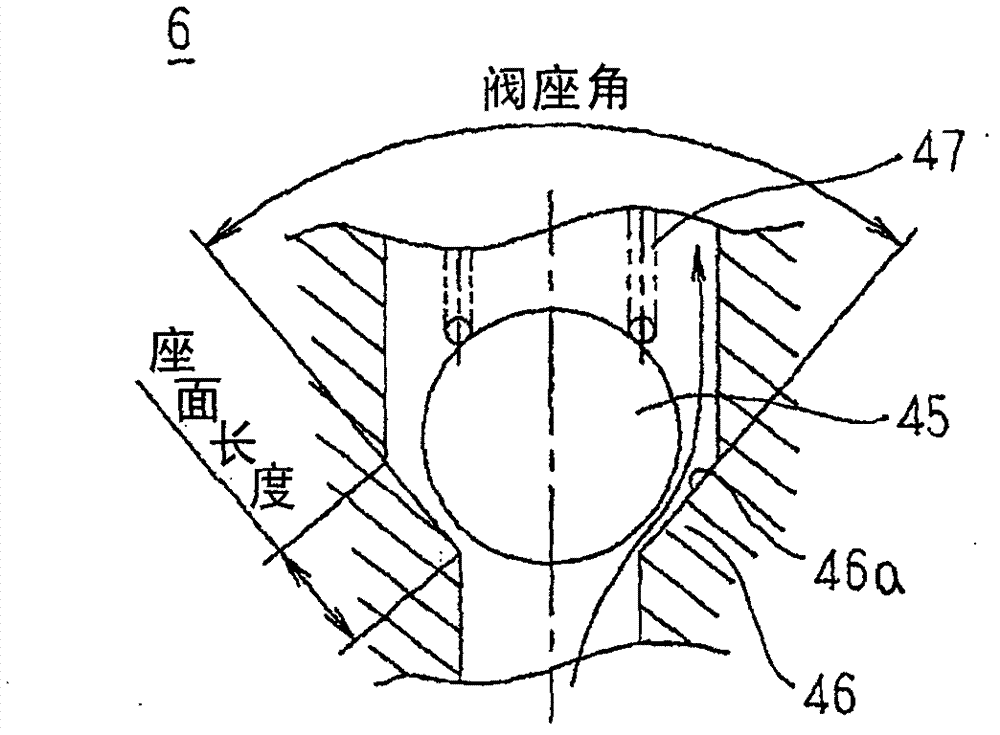

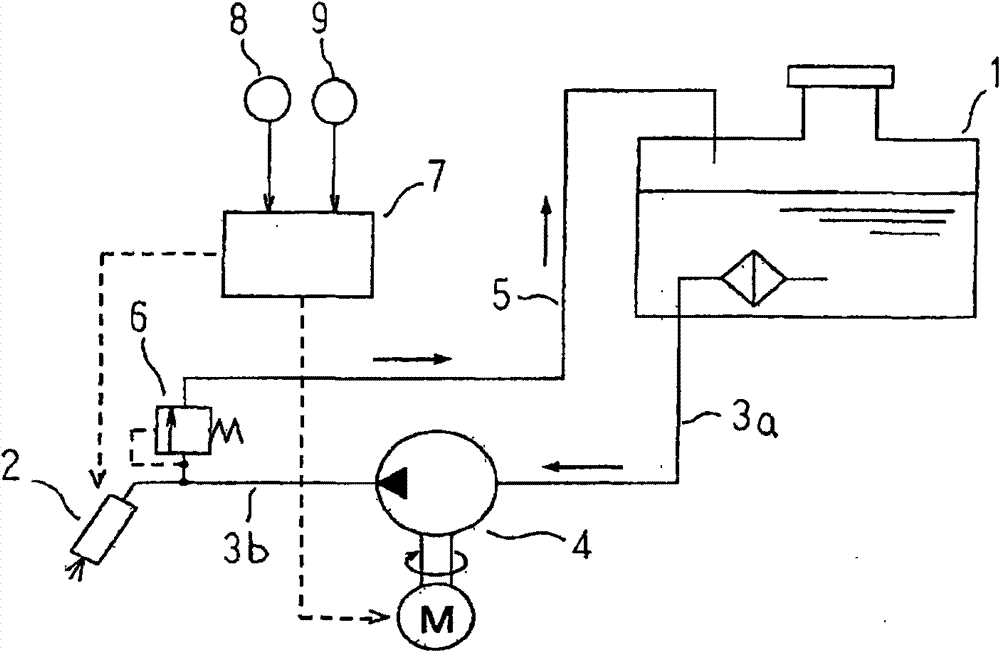

[0024] figure 1 is a diagram showing a system configuration of a fuel supply device according to an embodiment of the present invention, figure 2 It is a sectional view showing the structure of a fuel pump of a fuel supply device according to an embodiment of the present invention, image 3 It is a sectional view of main parts showing the structure of the pressure regulator device of the fuel supply system according to the embodiment of the present invention, Figure 4 It is a figure explaining the operation|movement of the pressure adjustment device of the fuel supply system which concerns on one Embodiment of this invention.

[0025] exist figure 1 Among them, the fuel supply device includes: a fuel tank 1; a fuel injection valve 2 that injects fuel toward an intake pipe (not shown) of the engine; the fuel that is sucked into the fuel tank 1 through a low-pressure pipe 3a, and injected toward the fuel through a high-pressure pipe 3b The fuel pump 4 that pumps fuel throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com