High-lift multi-stage centrifugal pump

A centrifugal pump, high lift technology, applied in the direction of pumps, pump components, non-variable-capacity pumps, etc., can solve the problems of prolonging the maintenance period, affecting the running performance, prone to errors, etc., and achieving the effect of improving the working performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

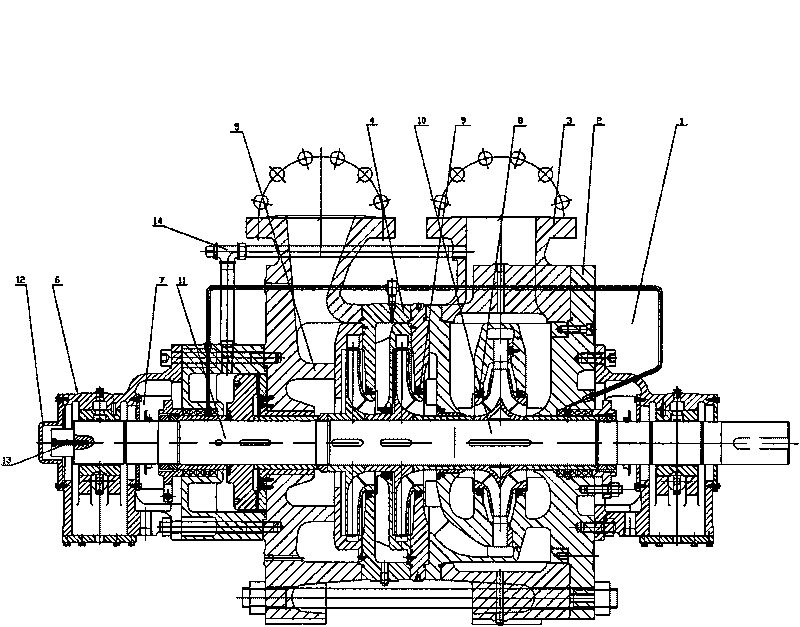

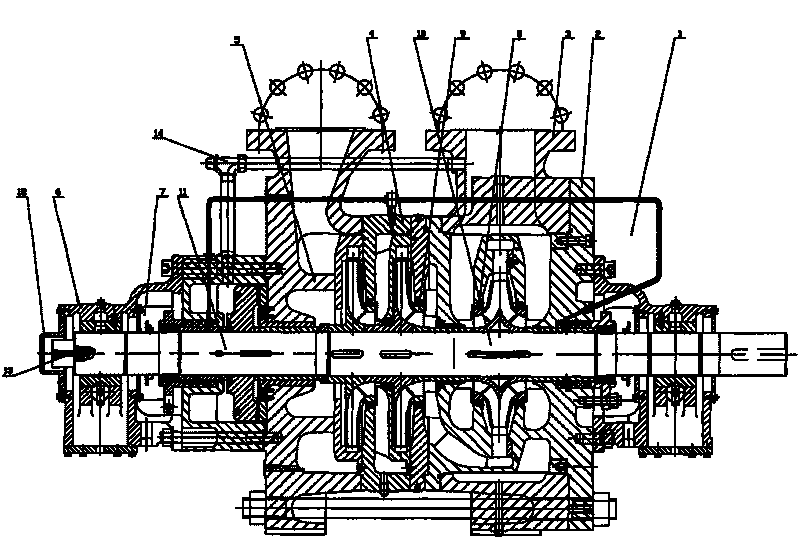

[0013] The present invention includes a pump base 1, a stator component and a rotor component. The stator component includes a water inlet end cover 2, a suction section 3, a middle section 4, a discharge section 5 and a bearing support component. The bearing support component includes a bearing component 6 and a bearing bush 7. The bearing component 6 includes a bearing seat and a sliding bearing connected thereto. A bearing bush 7 is provided between the sliding bearing and the rotating shaft. The rotor part includes an impeller 8, a rotating shaft 10, a bushing and a balance plate 11. The bearing part and the bearing bush 7 adopt a horizontal split structure. The end of the rotating shaft 10 is equipped with a balance plate wear indicator device, the first-stage impeller 8 adopts a double-suction structure, and the remaining stage impellers 9 adopt a single-suction structure.

[0014] The wear indicating device includes an indicating end cover 12 and a wear indicator 13, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com