Display and method for assembling same

A display and assembly technology, applied in the direction of instruments, optics, electrical components, etc., can solve the problems of increased heavy industry and maintenance costs, difficult handling, difficult production control, etc., to increase decorative effects and aesthetics, and reduce packaging and transportation costs , Improve the effect of product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

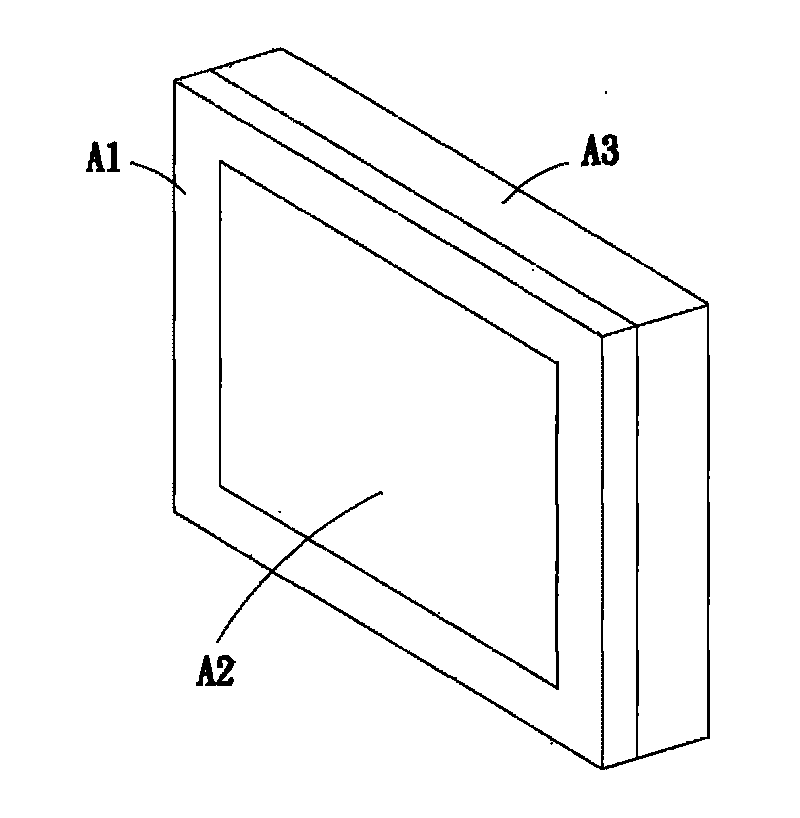

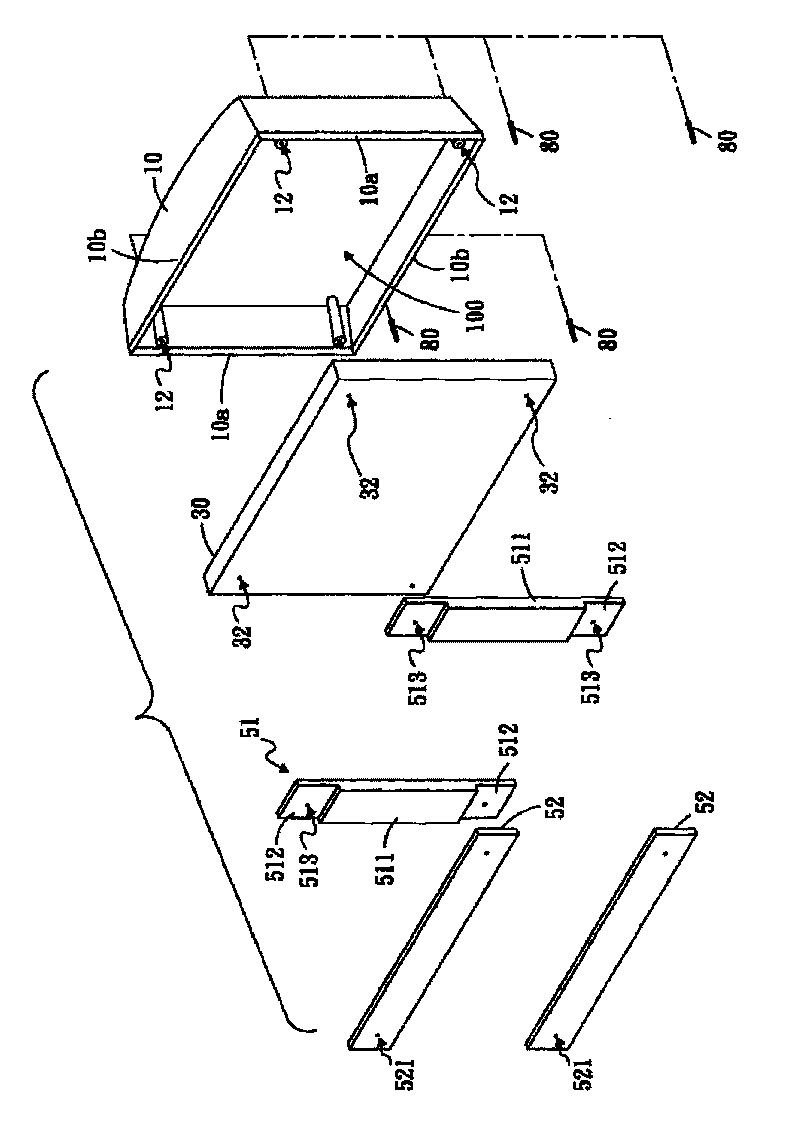

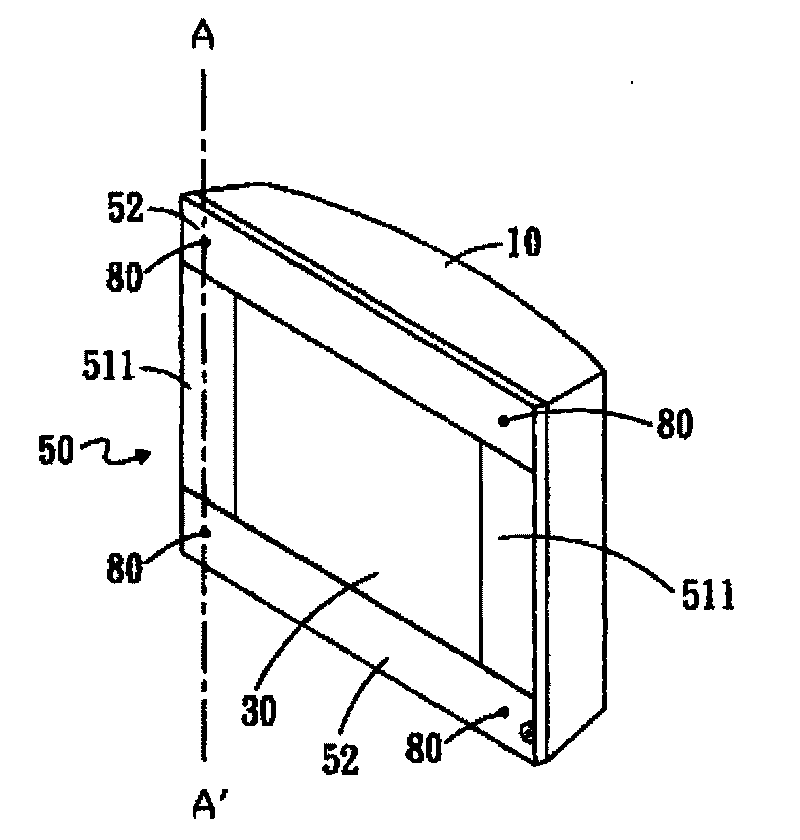

[0024] see figure 2 , image 3 , Figure 4A and Figure 4B As shown, the display disclosed in the first embodiment of the present invention includes a casing 10 , a display panel 30 , a front panel 50 , and a plurality of locking components 80 .

[0025] The casing 10 is generally rectangular, has two first sides 10a and two second sides 10b that are substantially perpendicular to each other, and forms an accommodating space 100. In addition, the casing 10 can be respectively pierced at four corners. Through hole 12 is established.

[0026] The display panel 30 is substantially rectangular and accommodated in the accommodating space 100 of the housing 10 . Here, the display panel 30 may be a liquid crystal display or a plasma display, but the present invention is not limited thereto. In addition, the display panel 30 can respectively define positioning holes 32 at the four end corners, and the positioning holes 32 and the through holes 12 are provided correspondingly.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com