A kind of ggnmos device and manufacturing method thereof

A manufacturing method and device technology, applied in the direction of semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of increasing the device area, reducing the slope of the conduction curve, affecting the ESD discharge capability, etc., and reducing the P-well Concentration, Improved Trigger Effect, Good Trigger Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

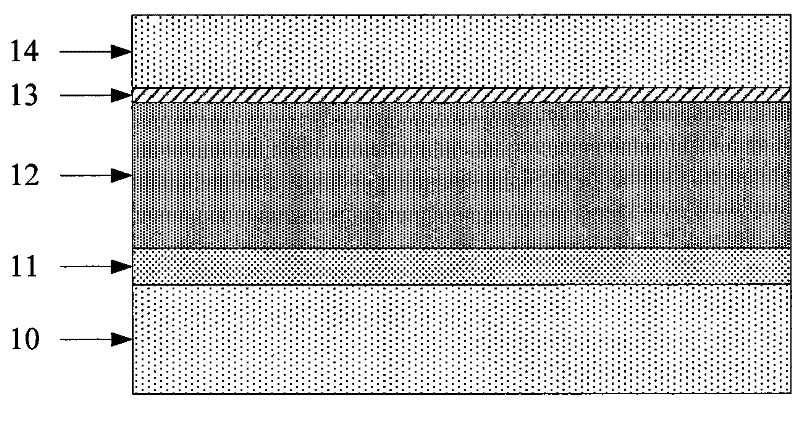

[0030] The manufacturing method of GGNMOS device described in the present invention, comprises the steps:

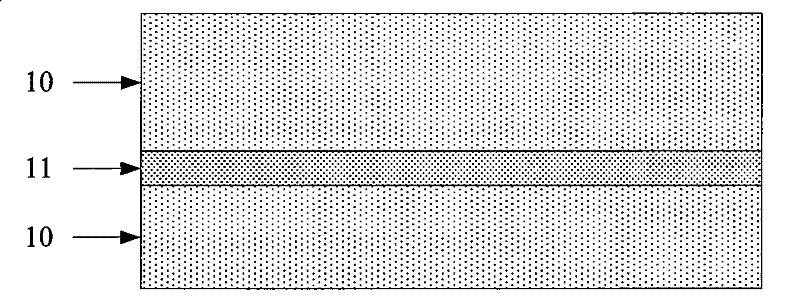

[0031] Step 1, see Figure 1a . N-type impurities are implanted on the P-type silicon substrate 10 by an ion implantation process to form a deep N well 11 . Commonly used N-type impurities are phosphorus, arsenic and antimony. Annealed in a high temperature furnace after ion implantation.

[0032] For example, the dose of ion-implanted phosphorus is 5×10 12 ions / cm 2 (ion per square centimeter) ~ 1.5×10 13 ions / cm 2 , the implantation energy is 1000keV-2000keV. The temperature of the high temperature furnace annealing is 1100° C. to 1200° C., and the time is 1 to 3 hours.

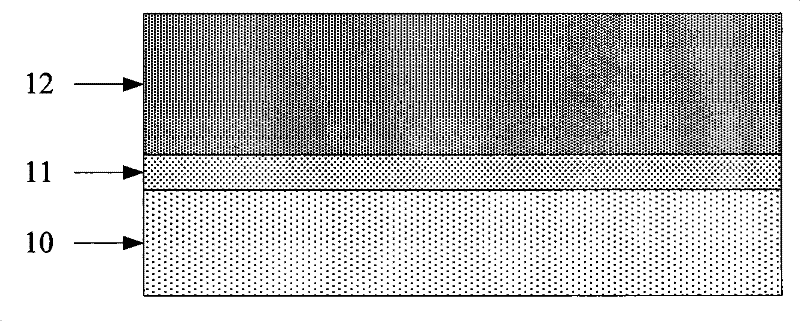

[0033] Step 2, see Figure 1b . P-type impurities are implanted on the P-type silicon substrate 10 by an ion implantation process, and the range of ion implantation is all silicon above the deep N well 11 , thereby forming a P well 12 on the deep N well 11 . Commonly used P-type impurities ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com