Separator for clutch

A separation device and clutch technology, applied in the direction of clutches, electric clutches, mechanical drive clutches, etc., can solve problems such as high energy, and achieve the effect of simple length, simple structure, and simple triggering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

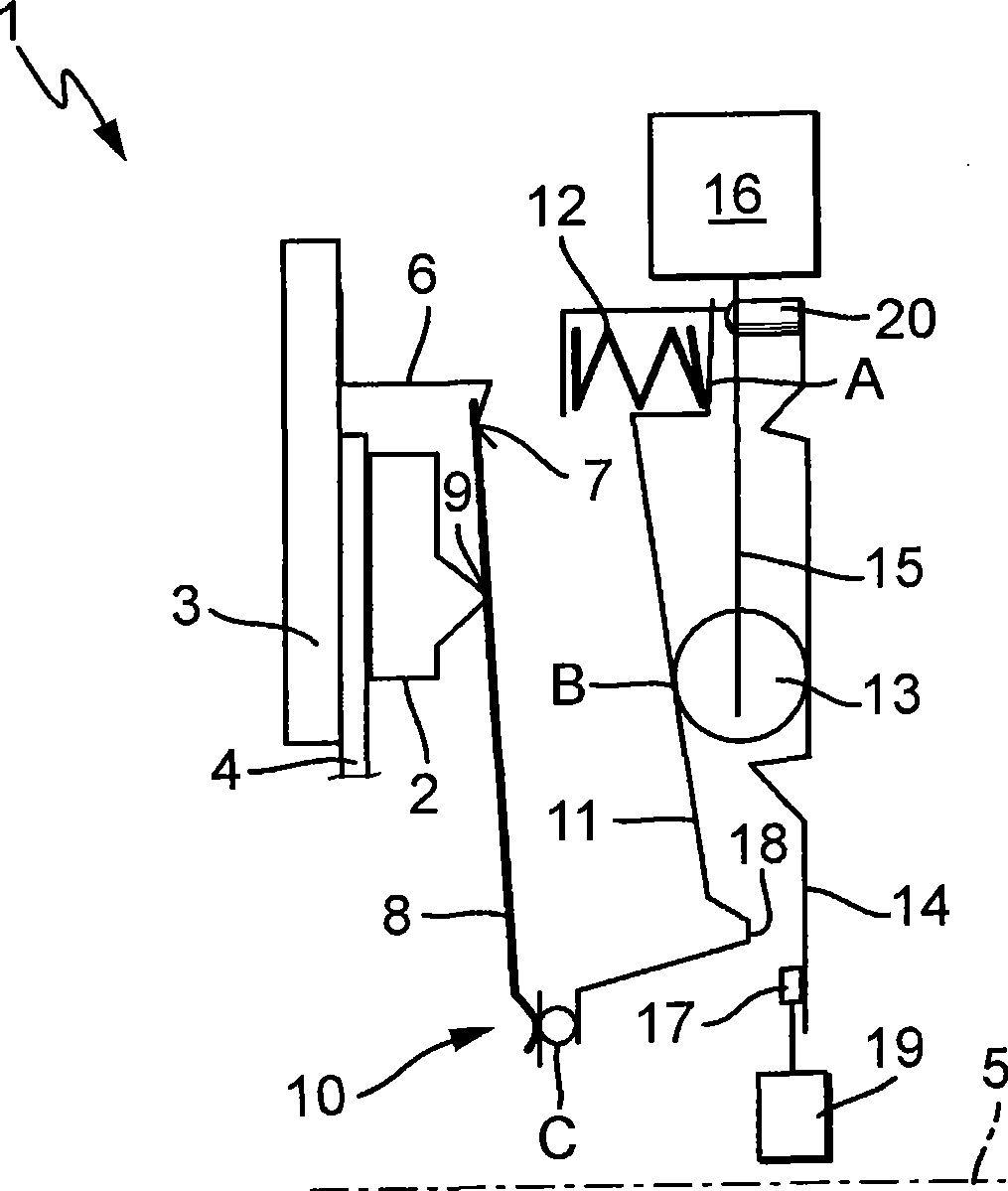

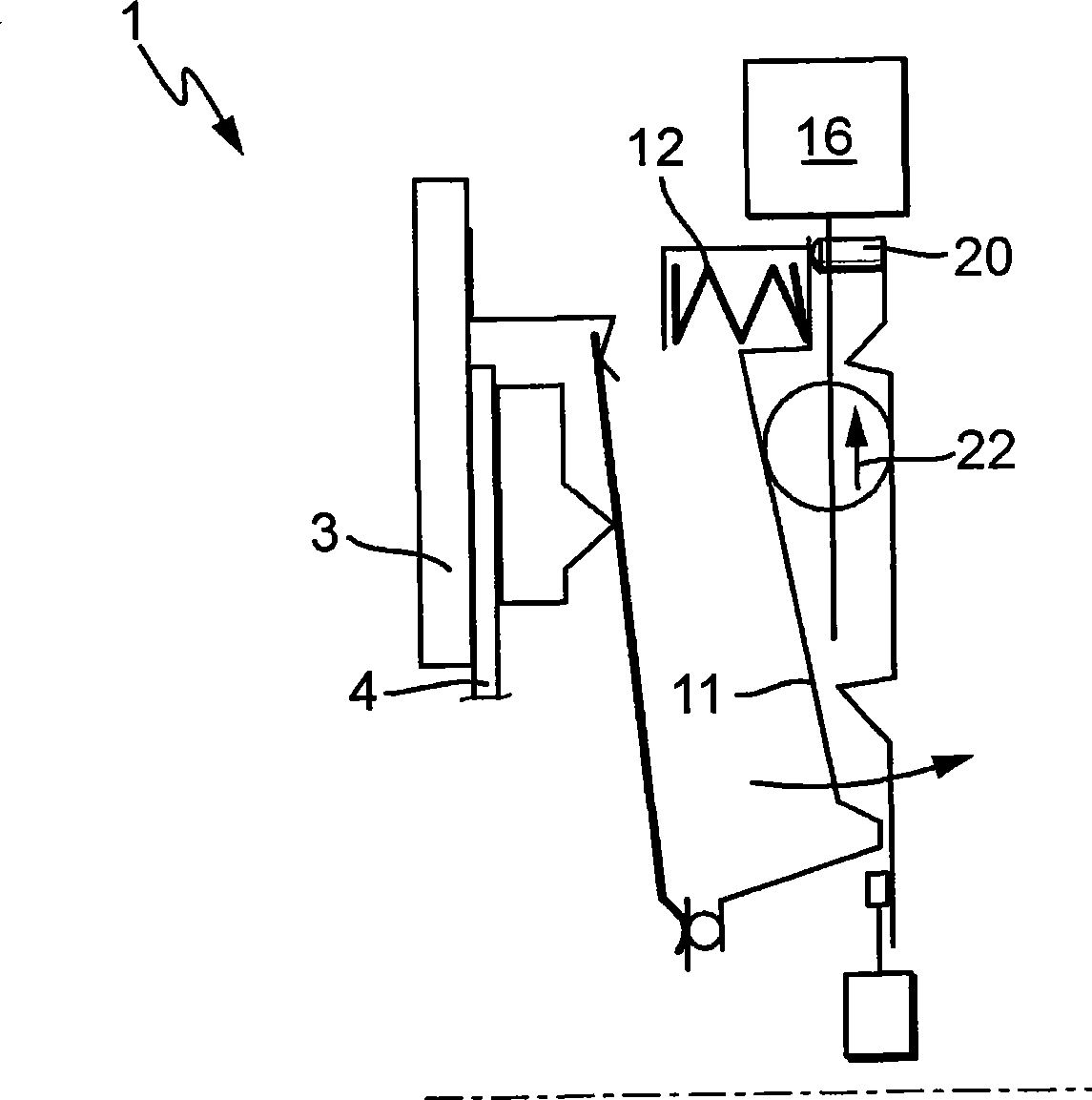

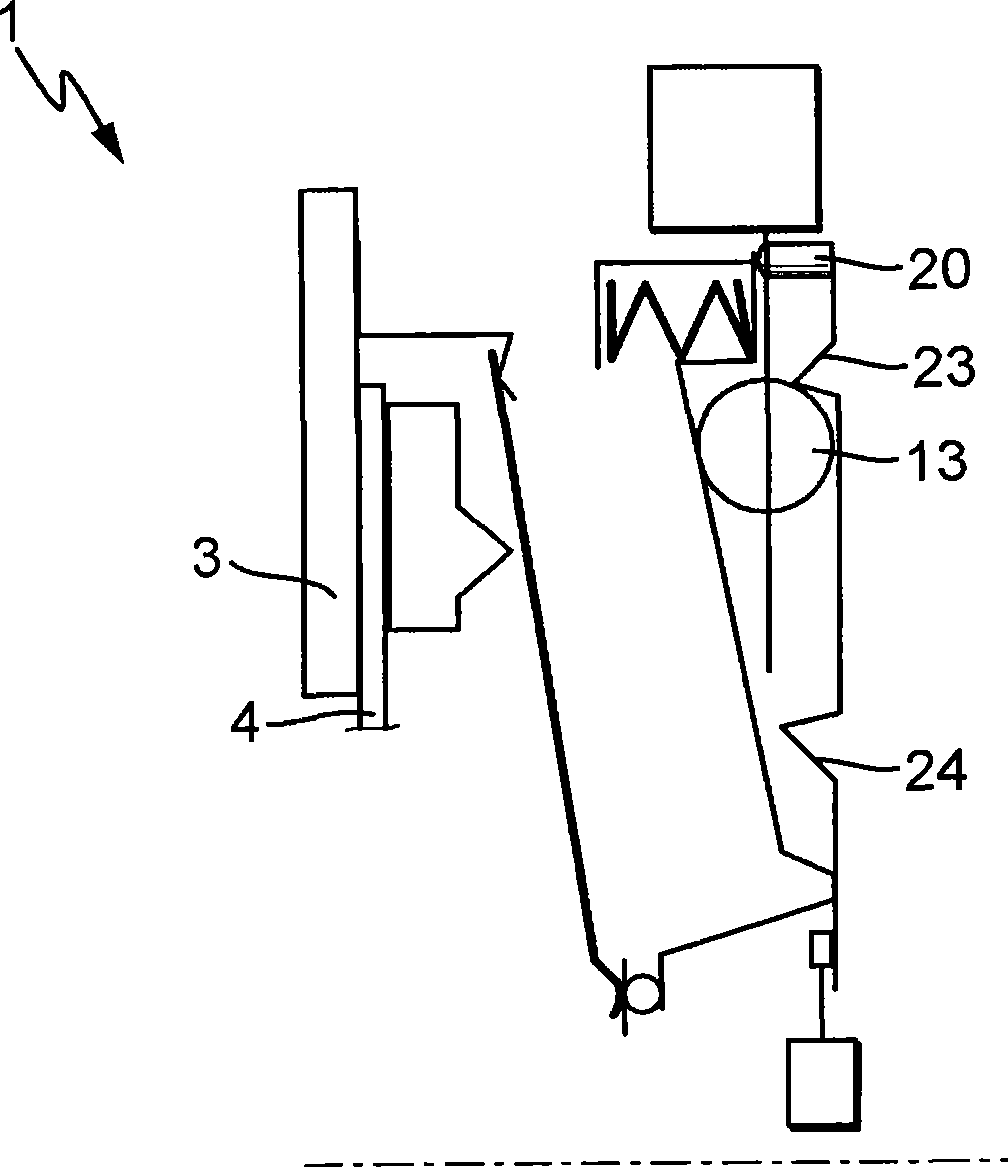

[0024] Figure 1 to Figure 3 A schematic view of a first embodiment of the disconnecting device according to the invention, the so-called rocker lever actuator, is shown. by means of figure 1 The principle structure of an embodiment of the separation device according to the present invention will be described. Although most of the parts or assemblies are rotationally symmetrical with respect to the axis of rotation of the crankshaft or the transmission input shaft, which are not shown in detail here, this representation has been intentionally omitted for reasons of clarity.

[0025] The clutch 1 basically comprises a pressure plate 2 , a counter pressure plate 3 and a clutch disk 4 arranged between the pressure plate 2 and the counter pressure plate 3 . The clutch disc 4 is connected to the transmission input shaft not shown here without relative rotation, and the counter pressure plate 3 is connected to the crankshaft not shown here, and the pressure plate 2 can rotate in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com