A method for improving and modulating the magnetoresistance of semi-metallic thin film materials by irradiation of high-energy heavy ions

A thin-film material and magnetoresistance technology, applied in the manufacture/processing of electromagnetic devices, can solve problems such as unfavorable practical applications and lowering the Curie temperature of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

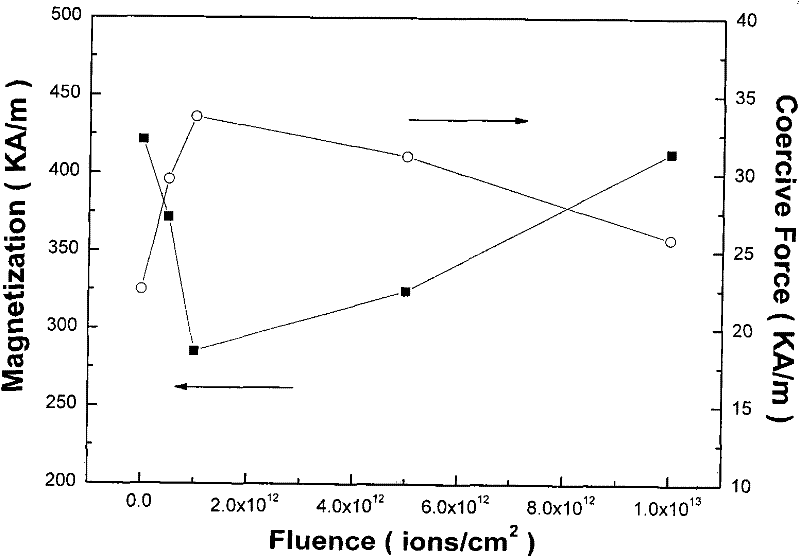

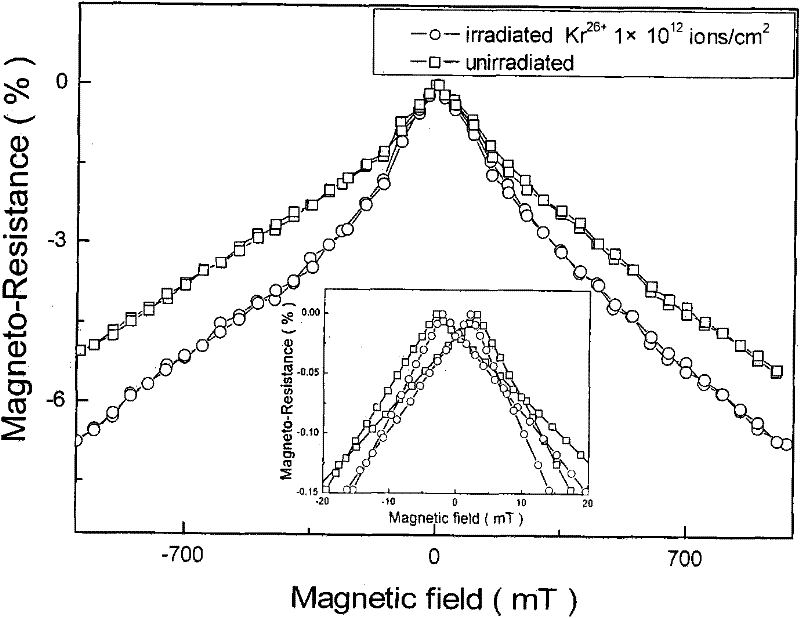

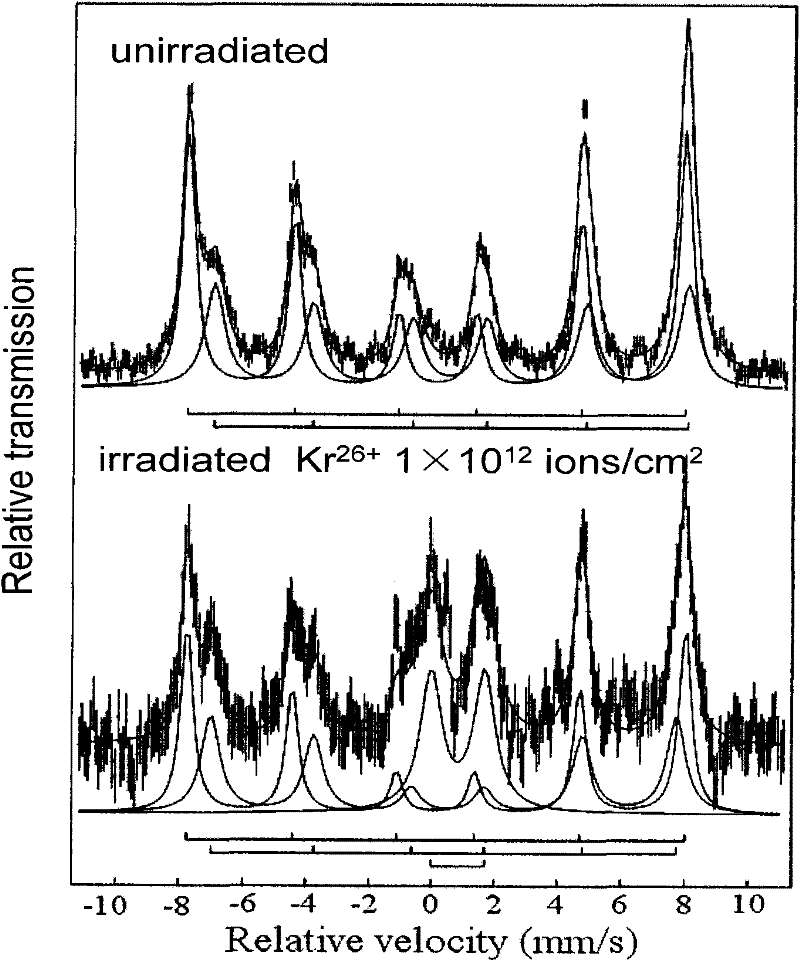

[0034] In this example, semi-metallic Fe 3 o 4 Nano polycrystalline film is taken as an example to illustrate the change of magnetoresistance at room temperature by using high-energy heavy ion irradiation to improve and modulate the magnetoresistance of semi-metallic film materials.

[0035] i. Semi-metallic Fe 3 o 4 The preparation of nano-polycrystalline thin film is to prepare positive fraction Fe on the glass substrate by means of spin spraying and electroless plating. 3 o 4 nano-polycrystalline film.

[0036] The specific method is: the FeCl 2 (0.01mol / L) was dissolved in deionized water to make a reaction solution, and 0.005mol / L of NaNO 2 and 0.1mol / L of CH 3 COONH 4 (pH buffer) dissolved in deionized water to make oxidation solution, adjust the pH values of the two reaction solutions to 5.5 and 6.9 respectively, inject the reaction solution and oxidation solution with nitrogen gas, and put them in a closed container through two special nozzles While reacting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com