Clamp for turning end face of flange of flange gate valve body

A technology of face turning and flanged gate valves, which is applied to turning equipment, manufacturing tools, turning equipment, etc., can solve the problems of low production efficiency, slow speed, large error, etc., and achieve the goal of ensuring processing quality, improving production efficiency and accurate positioning Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

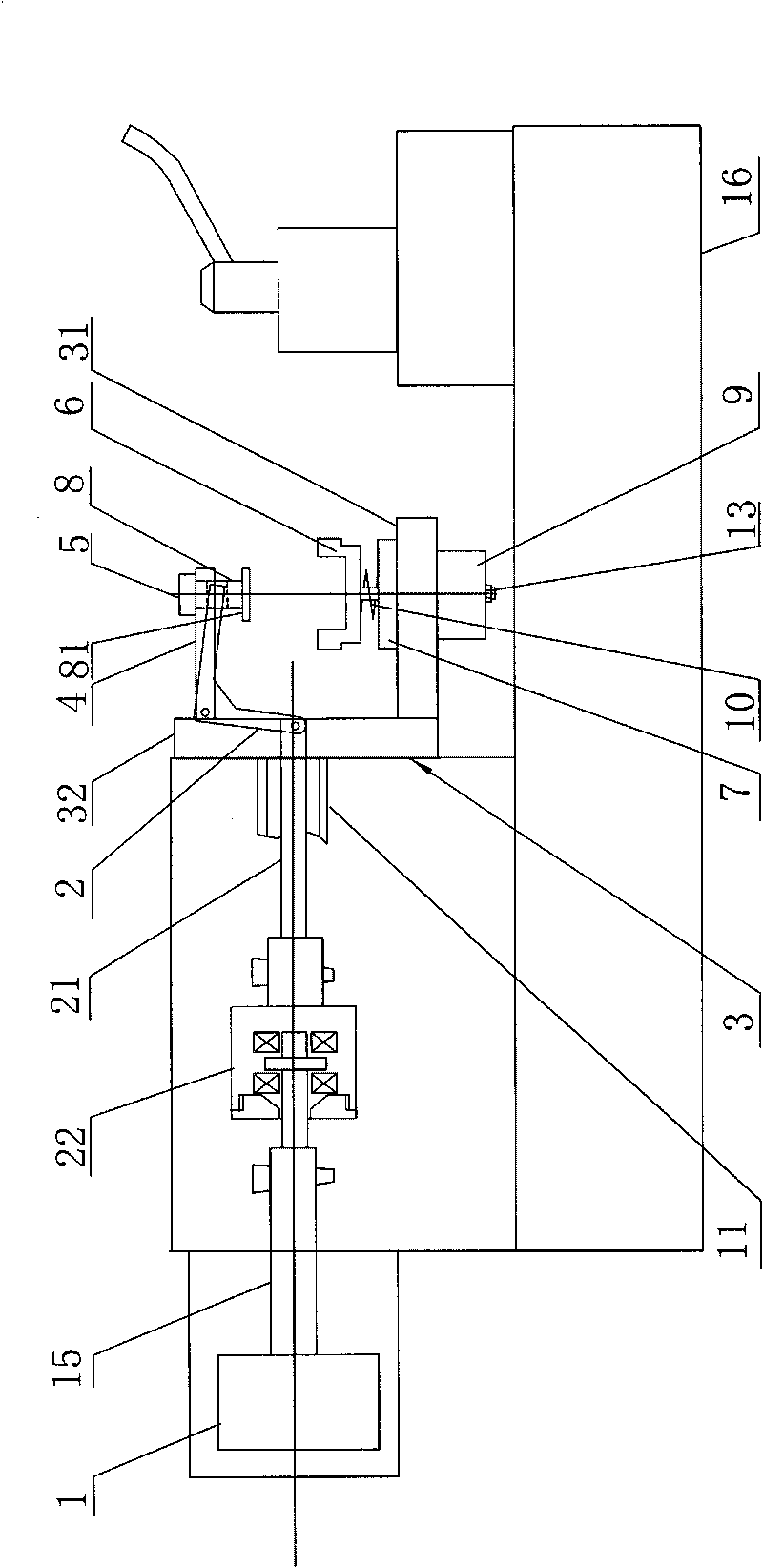

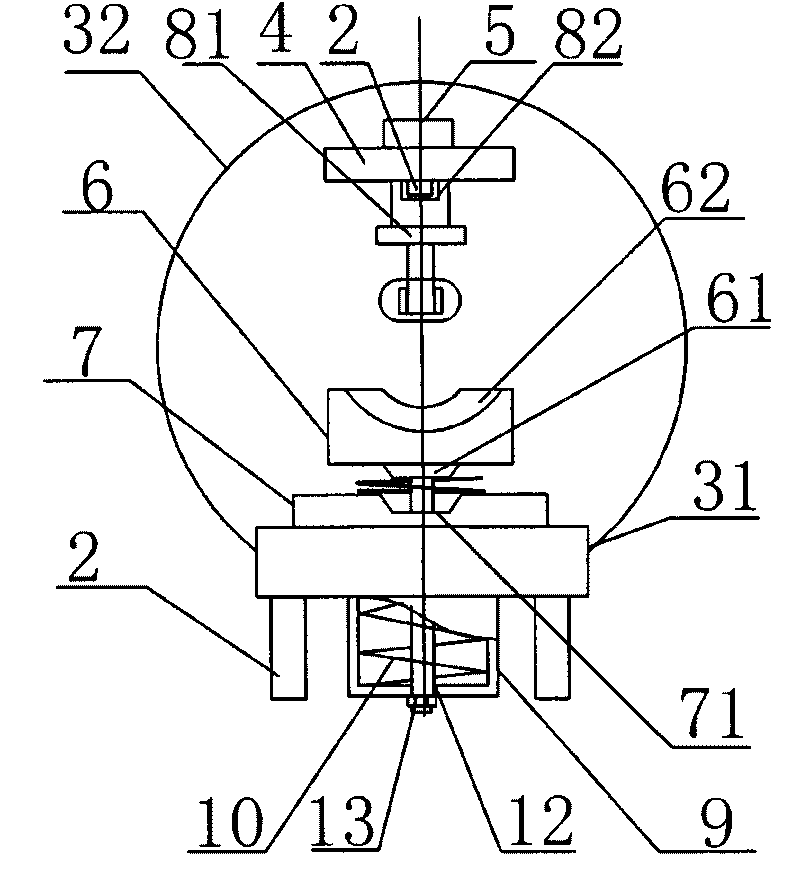

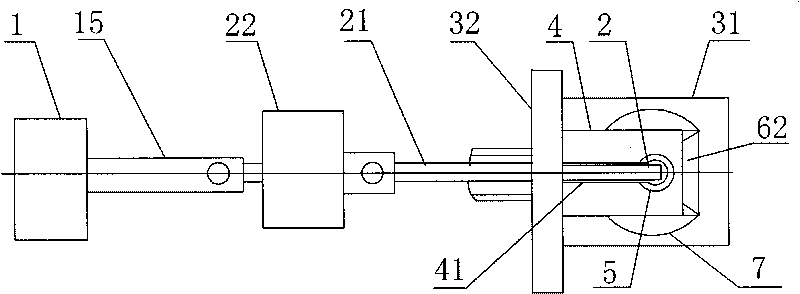

[0018] Figure 1 to Figure 6 It shows a jig for turning the flange end face of a flanged gate valve body and its application on a lathe, which is characterized in that the jig includes a right-angle bent plate 3, and is provided on the right-angle bent plate horizontal plate 31 for placing the valve body. 14 of the elastic positioning support assembly and the three parts of the pneumatic pressure head assembly for pressing down the valve body 14 on the circular right-angle bent plate vertical plate 32 vertically fixedly connected with the main shaft. Symmetrically arranged valve body supports 6, clamping plates 7, spring sleeves 9, springs 10, bolts 12 and adjustment nuts 13 are formed. The clamping plates 7 are fixedly installed on the above-mentioned right-angle bent plate horizontal plate 31, and the above-mentioned spring sleeves 9 runs through the horizontal plate 32 of the right-angled bent plate, and the clamping plate 7 is fixedly arranged on the horizontal plate 31 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com