Welding gun head of plastic spiral pipe

A technology for plastic winding pipes and pipes, which is applied in the field of welding torch heads for plastic winding pipes, can solve problems such as inability to form at one time, and achieve the effects of wide welding surface, compact structure, and ensuring the quality of welding connections.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

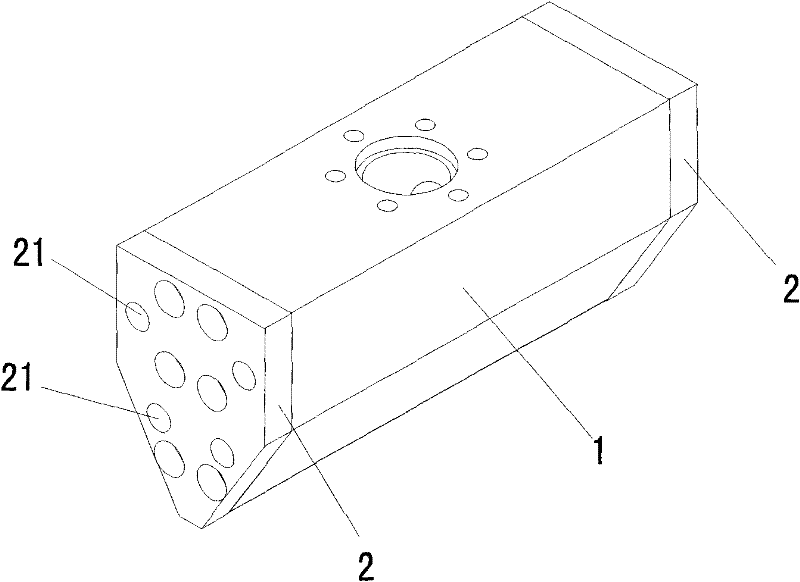

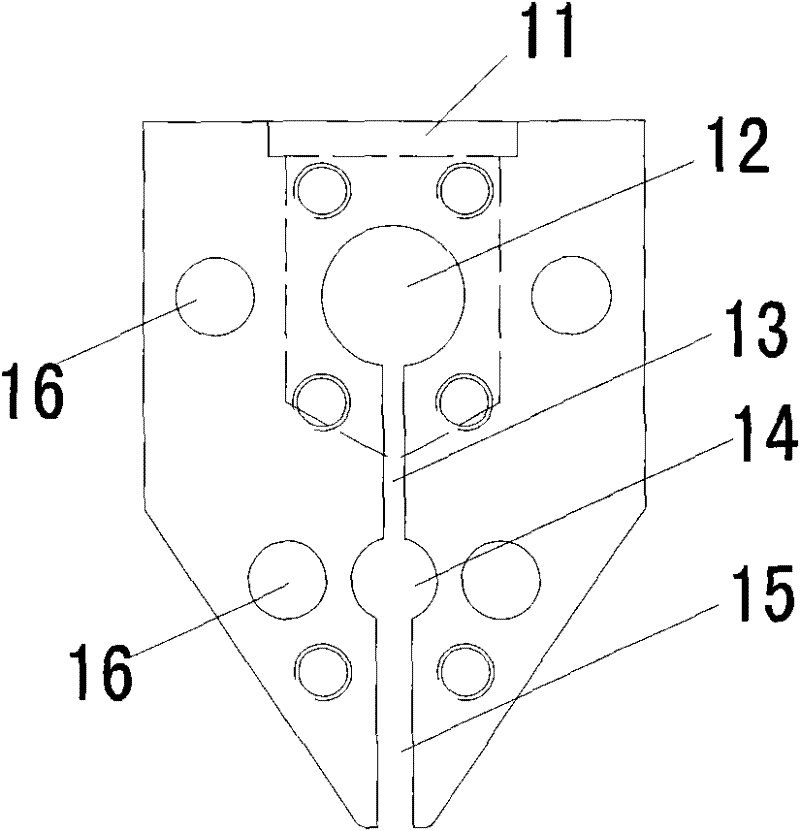

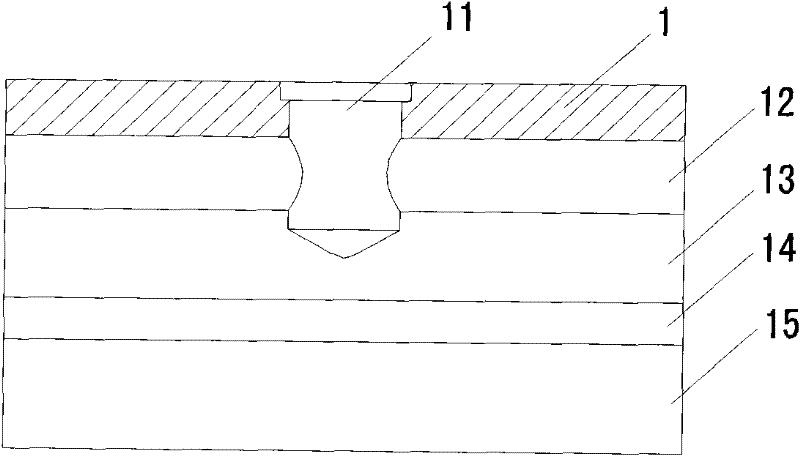

[0017] see figure 1 , figure 2 , image 3 , the welding gun head for the plastic winding pipe of the present invention includes a cavity 1, two end plates 2 and a heating element (not shown), the two end plates 2 are respectively sealed at both ends of the cavity 1, and the heating element is arranged at both ends within the solid body of the plate and cavity.

[0018] The cavity 1 among the present invention is provided with feeding hole 11, the first material storage chamber 12, the first passage 13, the second material storage chamber 14 and the second passage 15 in sequence from top to bottom and communicate with each other, the second passage 15 It is the outlet channel for the molten electrode. The first storage chamber 12, the first passage 13, the second storage chamber 14 and the second passage 15 respectively extend (or pass through) the length direction of the cavity 1 and have the same length, wherein the first storage chamber 12 and the second storage chamber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com