Centrifugal straight shaft rotary jet engine

A jet engine, centrifugal technology, applied in the direction of combustion engine, machine/engine, internal combustion piston engine, etc., can solve the problems of short life, high cost of crankshaft processing, large energy loss, etc., to improve service life, save energy loss, The effect of improving thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

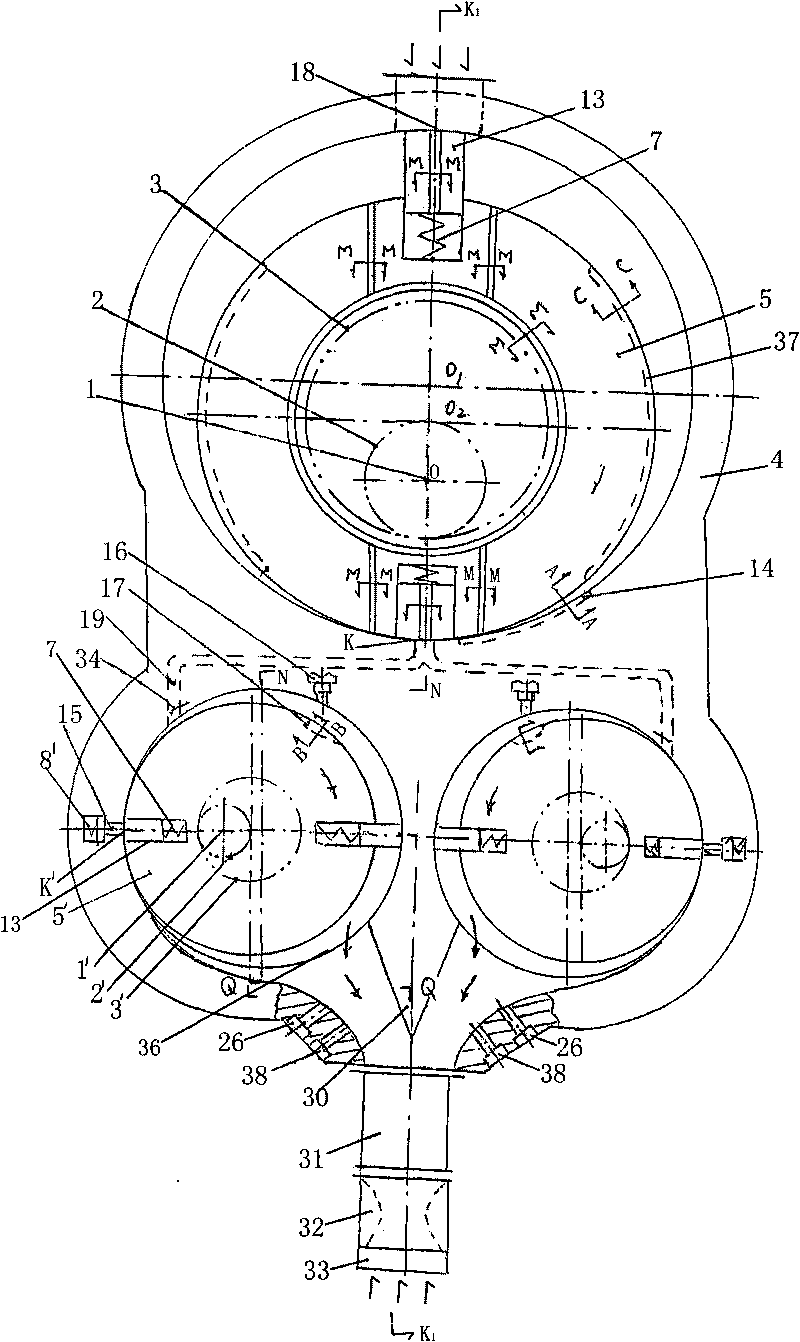

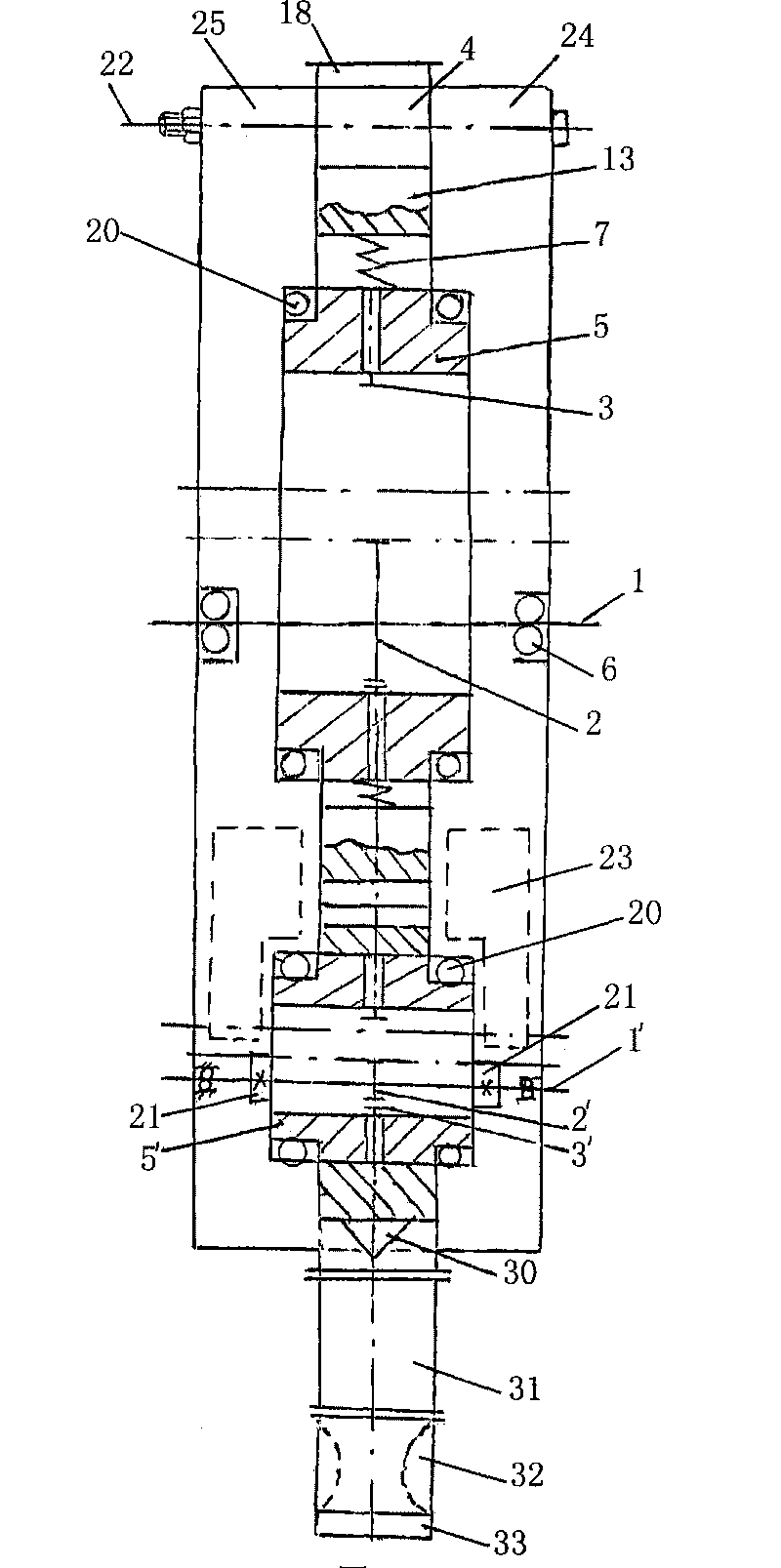

[0028] A centrifugal direct-axis rotor jet engine, comprising a main shaft 1, a rotor, a cylinder block 4, left and right cover plates (25, 24), an oil inlet 18, an exhaust port 33, left and right cover plates (25, 24 ) and the cylinder body 4 are fixed by fixing bolts 22; at least two rotors are arranged in the cylinder body 4, the cross section of the rotor is circular, the rotor is provided with a sliding seat, and the movement track of the rotor in the cylinder body 4 is a planetary track or a circular track . There are n sliding seats provided on the rotor, where n≥2 integers; the angles of the two adjacent sliding seats are equal.

[0029] Two rotors are arranged in the cylinder block 4 of this embodiment, and there are two sliding seats on each rotor. The rotor 5' is connected through a high-pressure oil inlet pipeline 19, the intake compression rotor 5 is arranged on the upper part of the cylinder body 4, and the chamber where the intake compression rotor 5 is located...

Embodiment 2

[0037] There are three rotors in the cylinder body 4, one air intake compression rotor 5, two power exhaust rotors 5', and two power exhaust rotors 5' are distributed symmetrically with the cylinder body 4 centerline. Others are with embodiment 1.

Embodiment 3

[0039] There are four rotors in the cylinder body 4, two air intake and compression rotors 5, two power exhaust rotors 5', two air intake compression rotors 5 and two power exhaust rotors 5' centered on the cylinder body 4 line symmetrical distribution. Others are with embodiment 1.

[0040] The working principle of the invention: After the oil is atomized and enters the intake compression rotor from the oil inlet, after being compressed, the intake compression rotor turns to the tangent point K and enters the high-pressure oil inlet pipeline through the dark channel. After pushing the reed valve, it enters the operating The spark plug in the chamber where the power exhaust rotor is located works, the reed valve closes, and the power exhaust rotor turns to the cylinder exhaust port to discharge the high-temperature gas in the chamber. At this time, the temperature drops to 1600K and the pressure is 5 atmospheres , in order to convert temperature and pressure into kinetic ener...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com