Combustion control method for regenerative-combustion heat treat furnace

A technology of heat treatment furnace and thermal storage combustion, which is applied in the direction of combustion method, combustion control, and treatment of combustion products, which can solve the problems of heat treatment furnace heat utilization rate reduction and achieve the effect of preventing the heat utilization rate from greatly reducing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Hereinafter, the combustion control method of the regenerative combustion type heat treatment furnace according to the embodiment of the present invention will be specifically described with reference to the drawings. In addition, the control method of the regenerative combustion type heat treatment furnace of this invention is not specifically limited to embodiment shown below, It can change suitably within the range which does not change the object of invention.

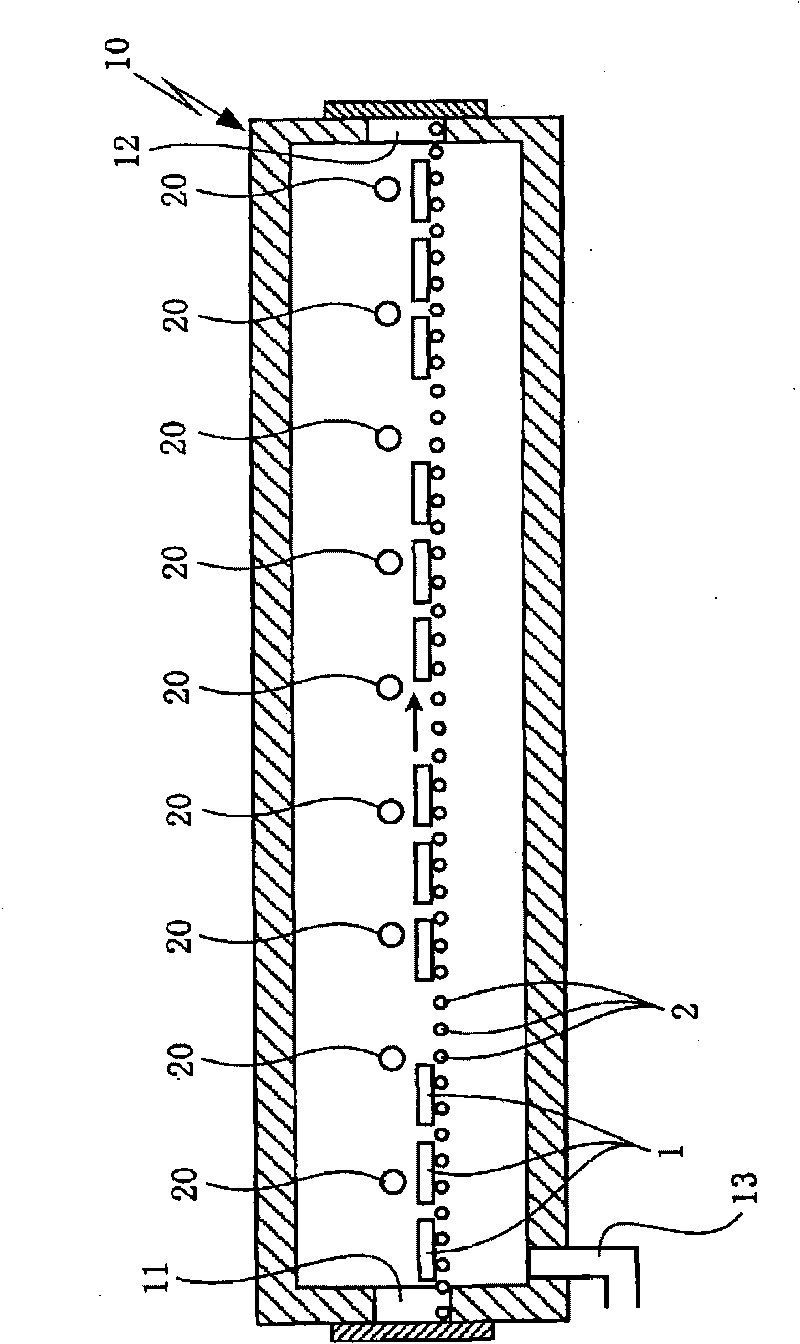

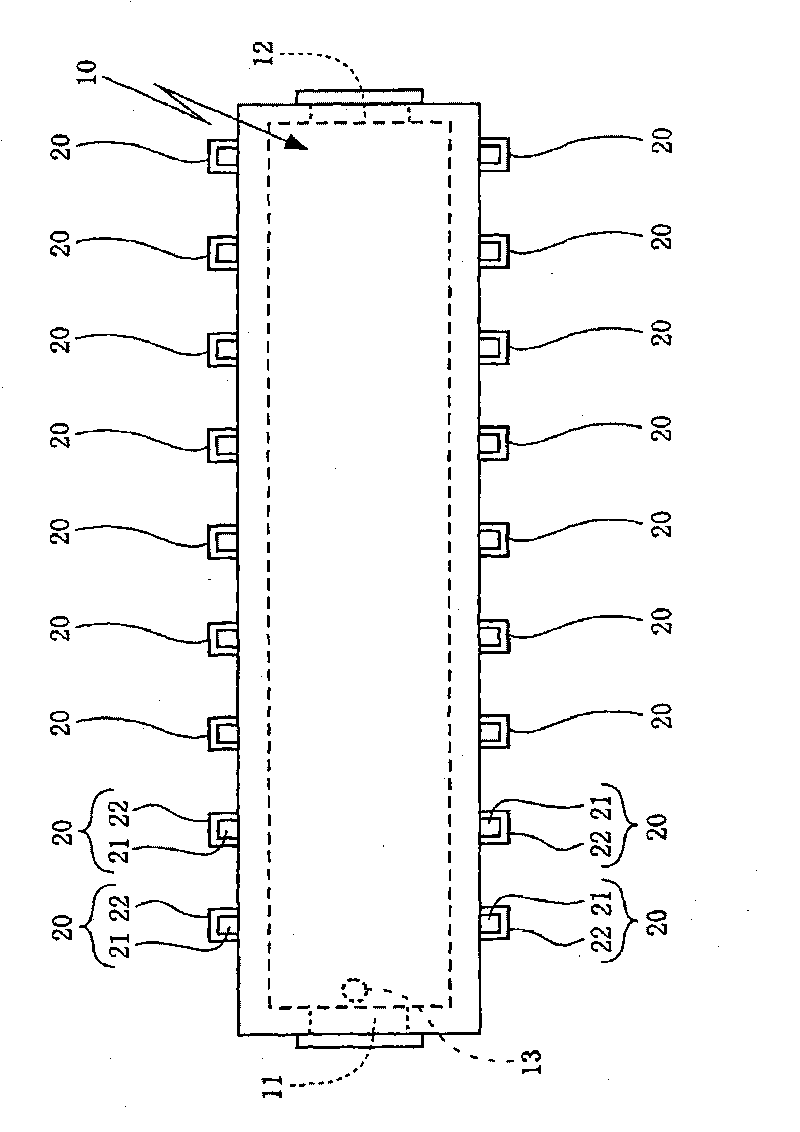

[0040] Here, if figure 1 As shown, in the present embodiment, the material to be processed 1 made of steel that is guided into the heat treatment furnace 10 from the inlet 11 of the heat treatment furnace 10 is transported into the heat treatment furnace 10 by the conveying roller 2 and heat-treated, and will be heat-treated as described above. The heat-treated material 1 to be processed is taken out of the heat treatment furnace 10 through the outlet 12 of the heat treatment furnace 10 .

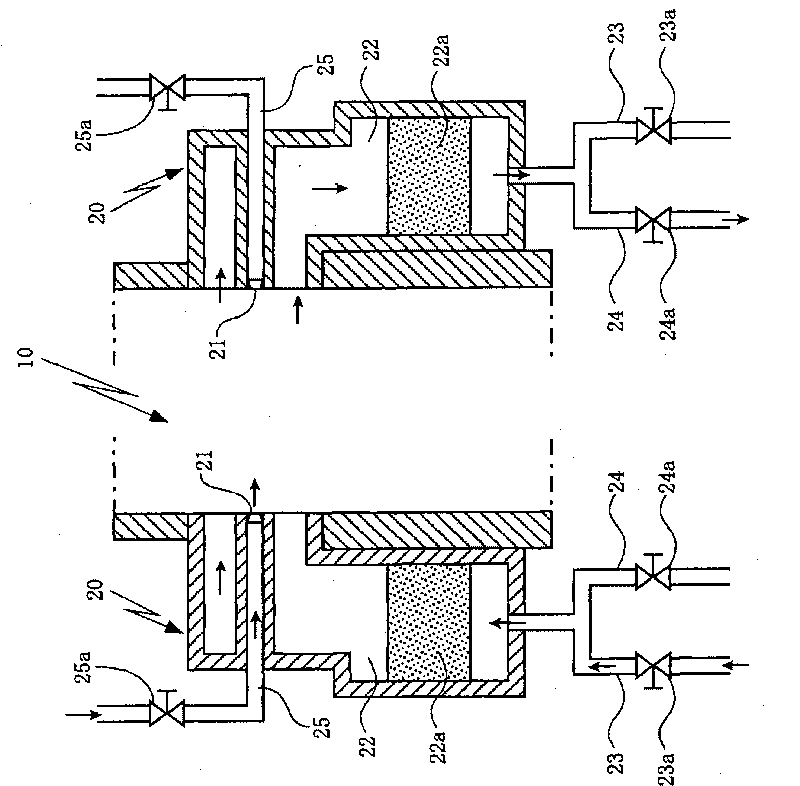

[0041] In additi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com