Feedback low-temperature bending test method and device for wire harness

A bending and wire harness technology, applied in the field of electronic component testing, to achieve intelligent control, experimental process and objective results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

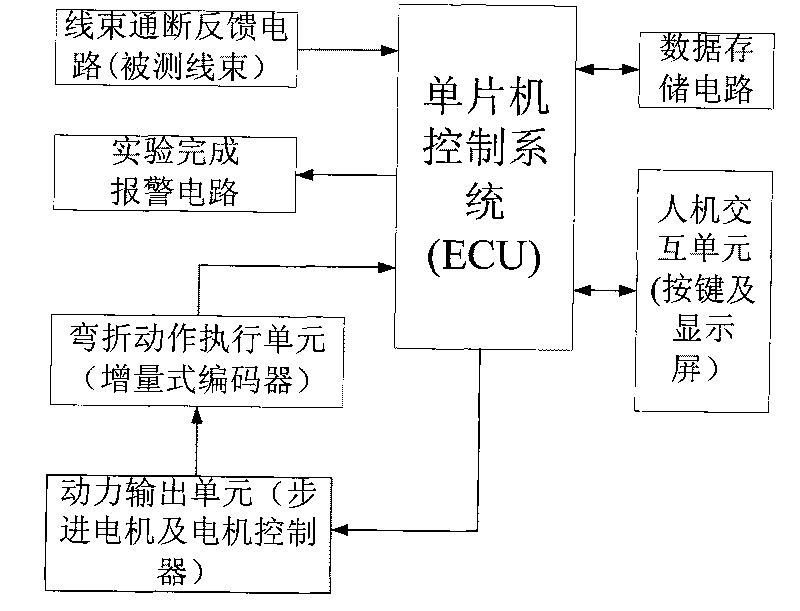

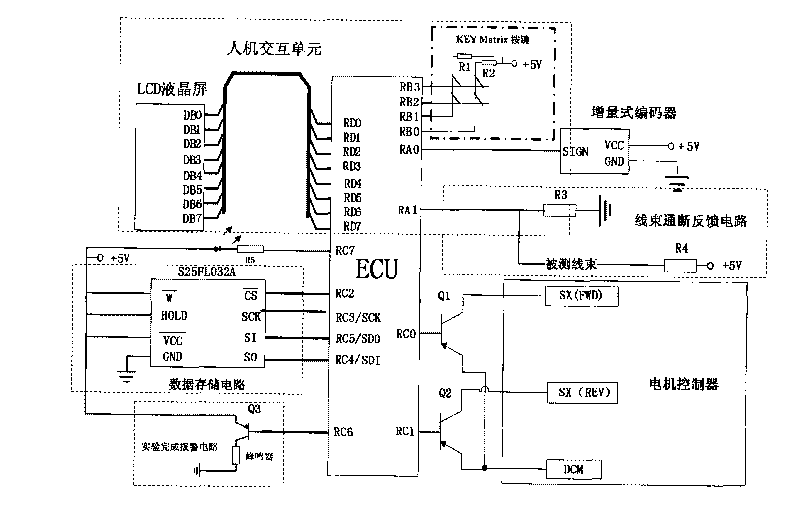

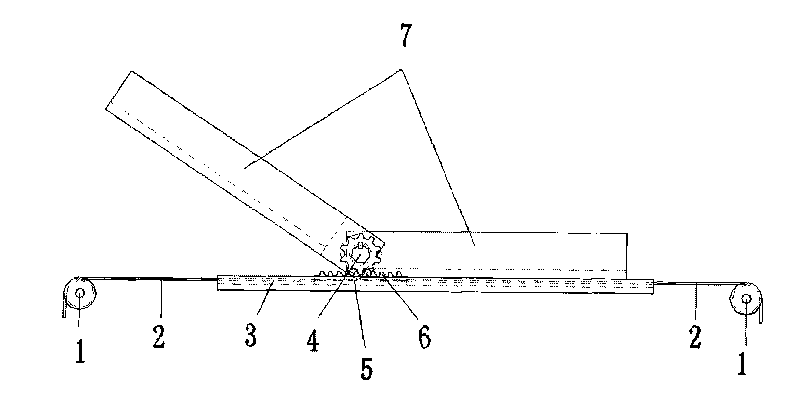

[0020] according to figure 1 As shown, the operation instructions input from the keys of the human-computer interaction unit are converted into control signals by the single-chip control system (ECU) and sent to the motor controller in the power output unit. The motor controller controls the operation of the stepping motor to provide stability for the bending action execution unit. driving force. The bending action execution unit provides feedback signals to the single-chip microcomputer control system through the incremental encoder installed at the rotating shaft while bending the tested wire harness. On the one hand, the feedback signal is used as the control signal of the single-chip control system (ECU), and after being processed by the single-chip control system (ECU), the experimental feedback information such as bending frequency and bending times can be observed in real time through the LCD liquid crystal screen of the human-computer interaction unit; The aspect sav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com