Automatic assembly method for three-dimensional ship modeling part

An automatic assembly and parts technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as inability to distinguish components, inability to assemble and analyze hull parts, etc., to achieve more types of objects, improve production design efficiency and High precision and high simulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0100] In order to make it easier for those skilled in the art to understand and implement the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. All the embodiments are operated according to the above-mentioned method, and each embodiment only records key technical data.

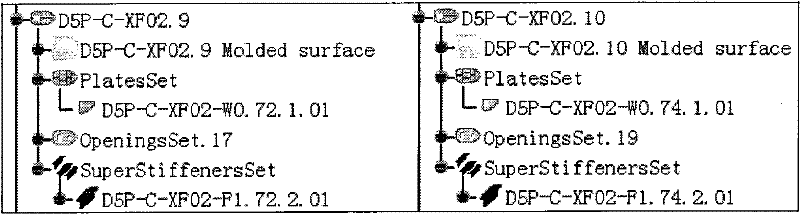

[0101] Such as Figure 6 As shown, there are multiple groups with the same name XF02 under the group in D5P-C, and only two of them are shown now. It can be seen from the figure that the distance between the center of gravity of the part "XF02-F1.1" and the part "XF02-W0.1" in the group is smaller than that of the part "XF02-W0.2" outside the group, and the distance between the center of gravity of the part "XF02-F1. 2" as well. The reason for this principle is that the parts in the group are welded together, and the distance between their centers of gravity must be close. Even if the center of gravity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com