Method for controlling the generation of suds in a washing machine and a washing machine suitable therefor

A washing machine and soap solution technology, which is applied to the control device of the washing machine, other washing machines, washing devices, etc., can solve the problem of soap liquid running out, and achieve the effects of preventing soap liquid production, ensuring cooling, and promoting production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

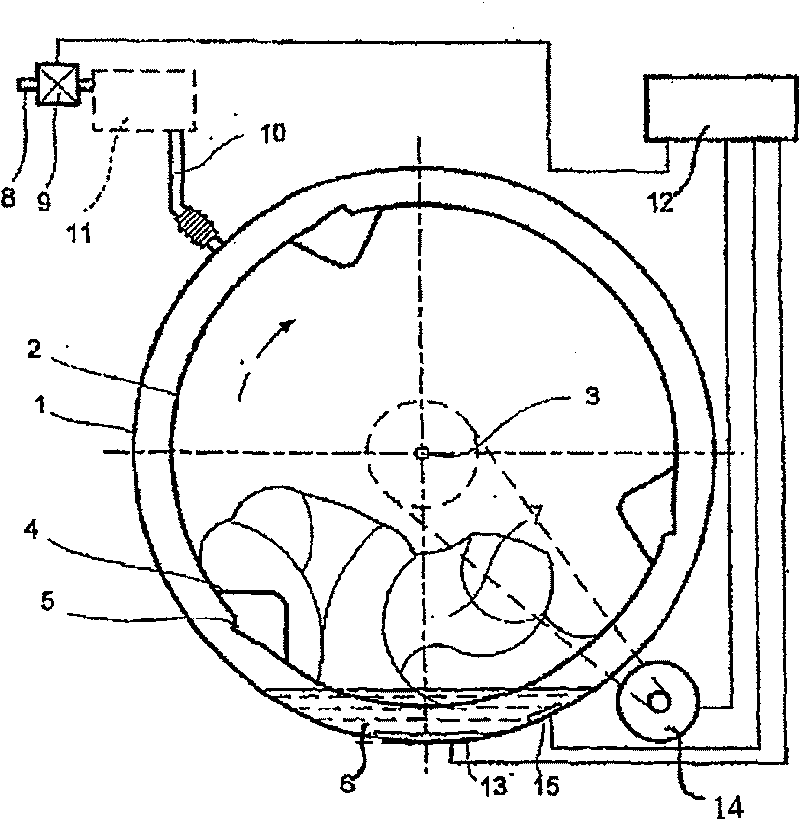

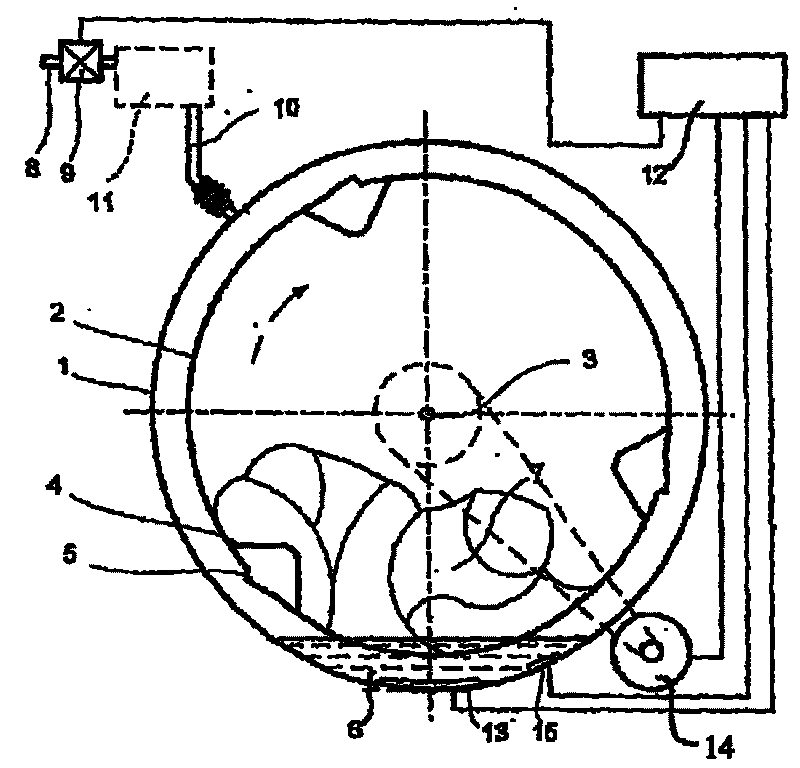

[0055] figure 1 is a schematic view of a part of a washing machine in which the described method relevant for explanation is implemented. Such as figure 1 The washing machine of the illustrated exemplary embodiment is provided with an outer tub 1 in which a drum 2 is rotatably mounted and can be driven by means of a drive motor 14 . With respect to ergonomics when using such a washing machine, the axis of rotation 3 of the drum 2 is inclined upwards and forwards at a small angle (eg 13°) from horizontal to provide easier access and viewing of the interior of the drum 2 . By this structure in combination with a specially formed laundry agitator 4 for washing liquid 6 on the inner surface of the drum shell and a supply means 5, an enhanced flow of laundry 7 for washing liquid and soap and a reduction in free washing liquid is also achieved .

[0056] The soap formed during the laundry method using soap should especially fill the space between the drum 2 and the tub 1 .

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com