Ultra-silent treadmill belt and manufacture method thereof

An ultra-quiet, treadmill technology, used in textiles and papermaking, fabrics, textiles, etc., can solve problems such as slippage, affect safety, and wear of the bottom yarn, and achieve enhanced tensile strength and fabric wear resistance. Safety and life, the effect of improving surface flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] An ultra-quiet treadmill belt, which uses fabric as a base material, and coats a base coat and a surface coat on the fabric, wherein the fabric is woven with a 3 / 1 twill weave, and its warp direction adopts shrinkage ratio It is 2% ultra-low shrinkage polyester polyester multifilament, and the weft direction adopts ultra-low shrinkage polyester monofilament with a shrinkage rate of 0.5%, and adds conductive filaments in the warp direction of the fabric (adding one every 1cm to 2cm); The primer layer is a pasty polyvinyl chloride resin with a viscosity of 9000-10000CP.

[0041] The surface coating is adjusted according to the formula shown in the following table:

[0042] Material

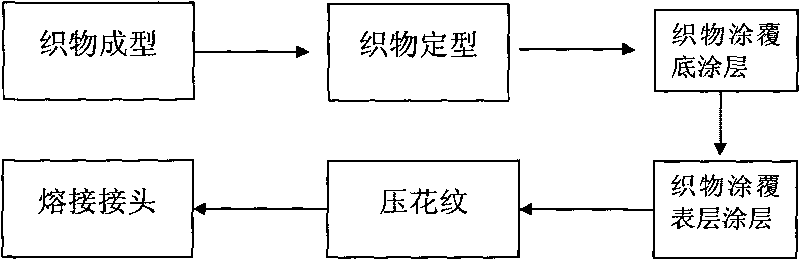

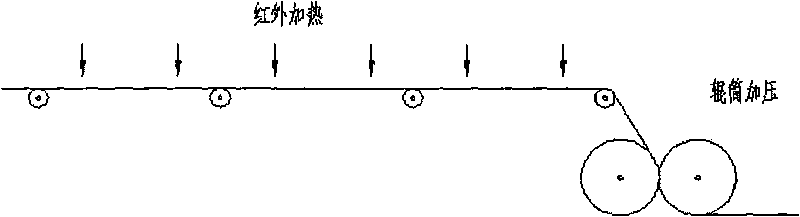

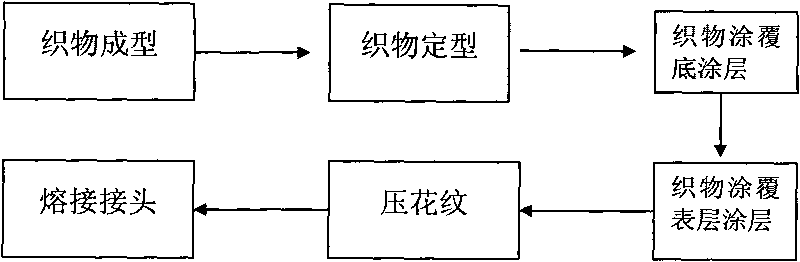

[0043] Manufacturing steps such as figure 1 As shown in the process flow chart of the present invention, it is produced in the following steps in sequence: fabric weaving, roller pressurization and heating and ironing to set the shape, primer coating on the fabric and no pressure o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shrinkage | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com