Diagonal rolling double-roller puncher having cast-weld structure

A technology of casting and welding structure and piercing machine, which is applied in the direction of metal rolling stand, metal rolling mill stand, metal rolling, etc. The equipment is cumbersome and other problems, to achieve the effect of rationalizing the overall effect, facilitating maintenance and adjustment of the equipment, and saving the time for replacing the guide plate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

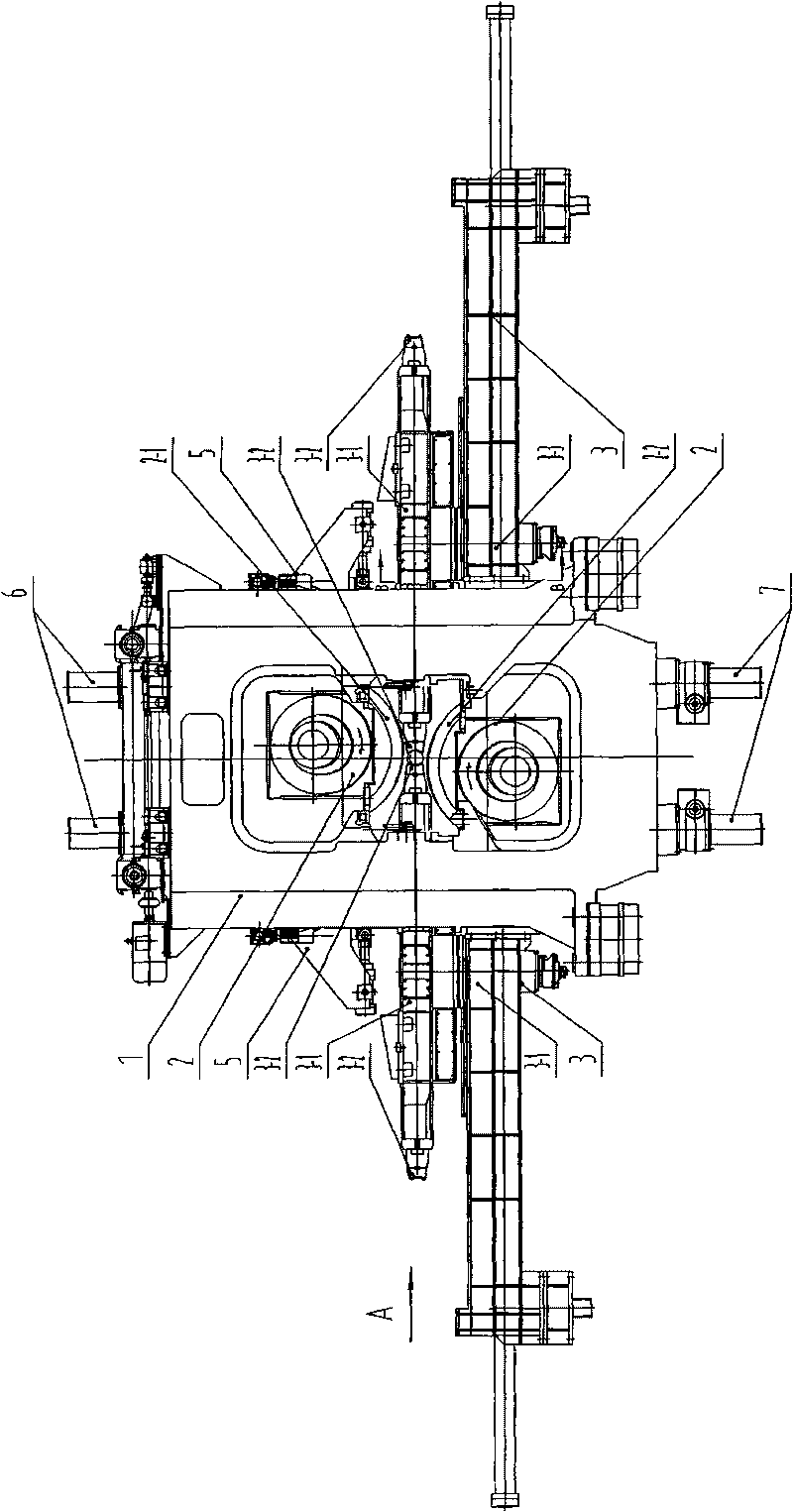

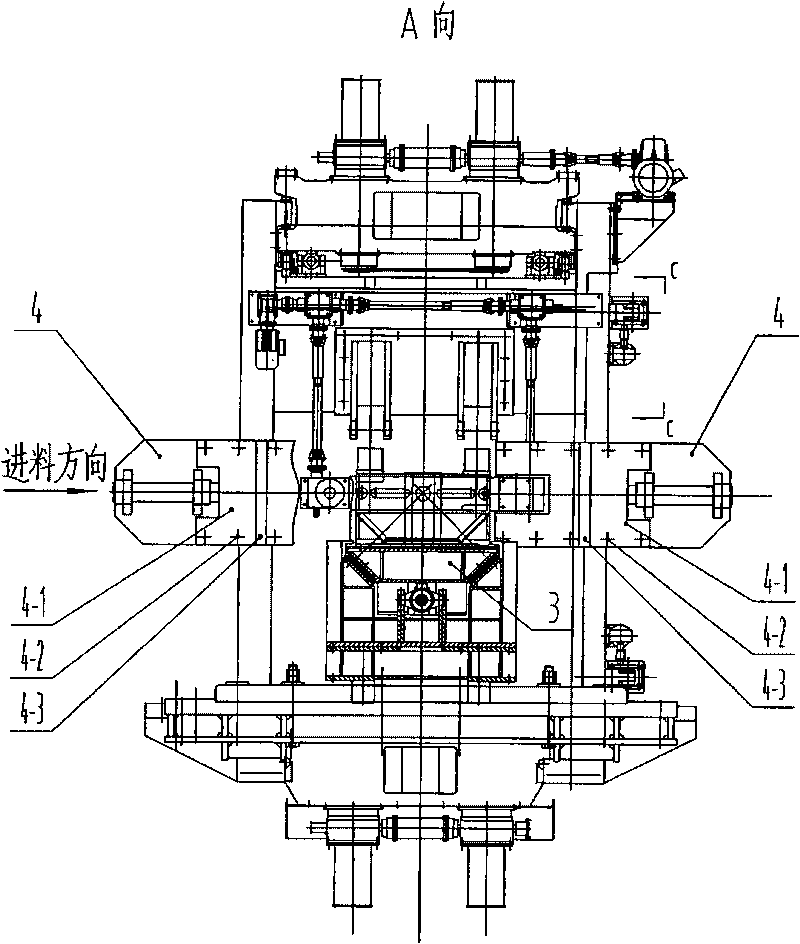

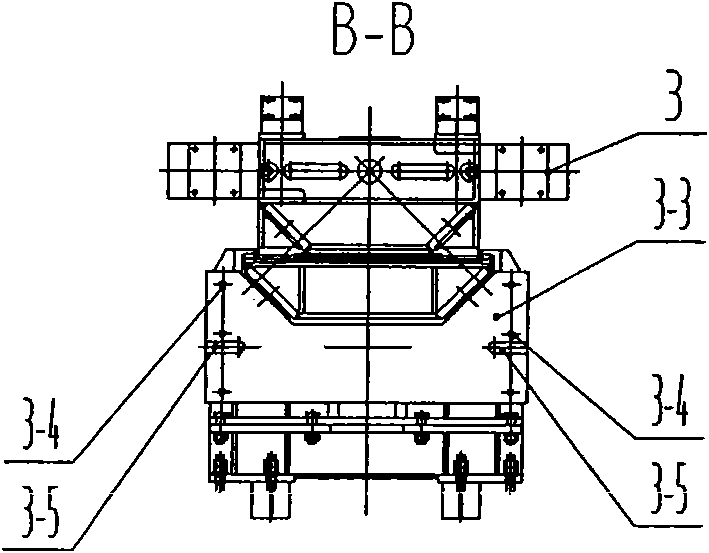

[0017] Such as figure 1 , 2 As shown in , 3 and 4, a cross-rolling two-roll piercer adopting a cast-welded structure includes: a main frame 1, two roll devices 2 placed in the main frame, placed on the left and right sides of the main frame 1 The two guide plate devices 3, the guide plate locking device 4, the guide plate adjusting device 5, and the pressing device 6 and the pressing device 7 for respectively adjusting the distance between the two roller devices.

[0018] The main body frame 1 is a casting, which eliminates irregular parts, leaving only a closed frame structure, which improves the casting process; since there is no surrounding redundant material connected to it, it can be designed as a pure The eight-beam and four-column frame body is an ideal stress-receiving body, which specially bears the rolling pressure transmitted by the two rolls 2-1 and 2-2.

[0019] The two roller devices 2 described are installed in the main body frame 1 and are slidably matched wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com