Method for forming mold for drilling high-strength bolt holes for coke dry quenching body frame structure

A body frame and high-strength bolt technology, applied in the field of CDQ, can solve the problems of difficult management of connecting plates and complicated actual operation, and achieve the effects of wide application range, high perforation rate, and guaranteed drilling accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

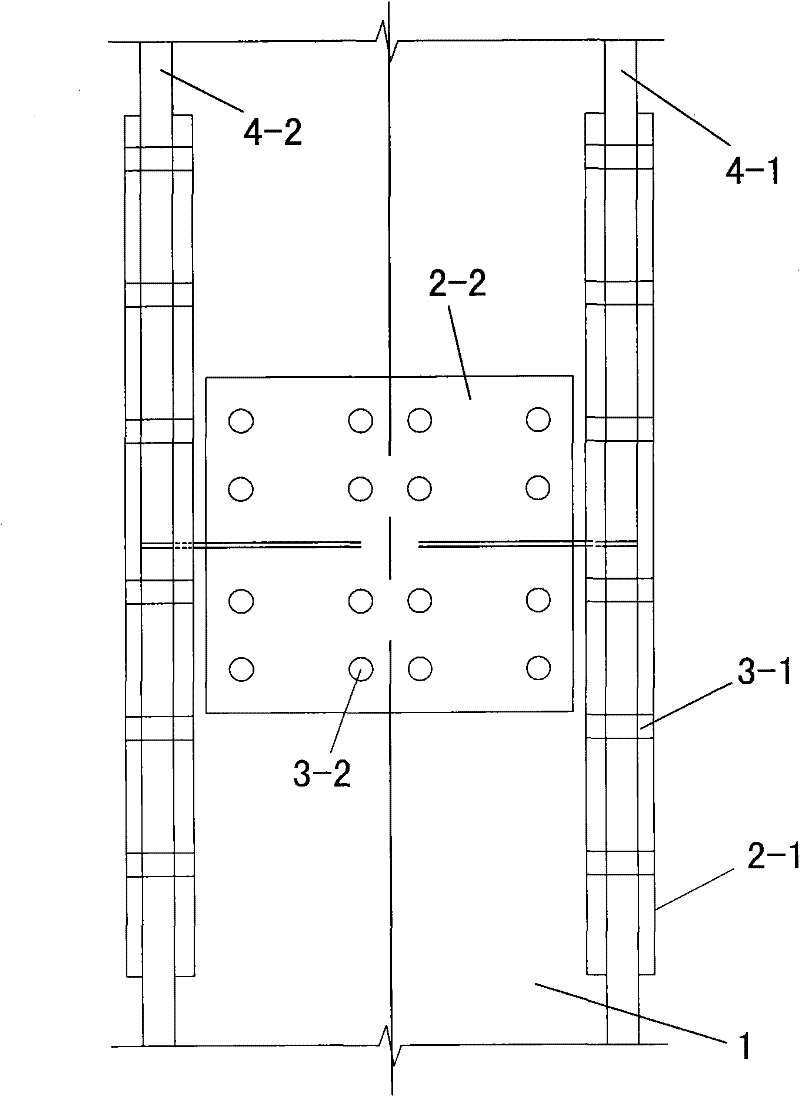

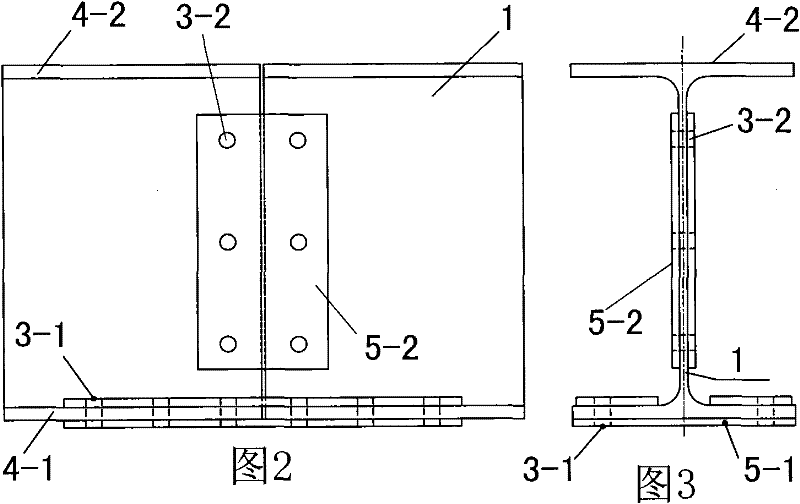

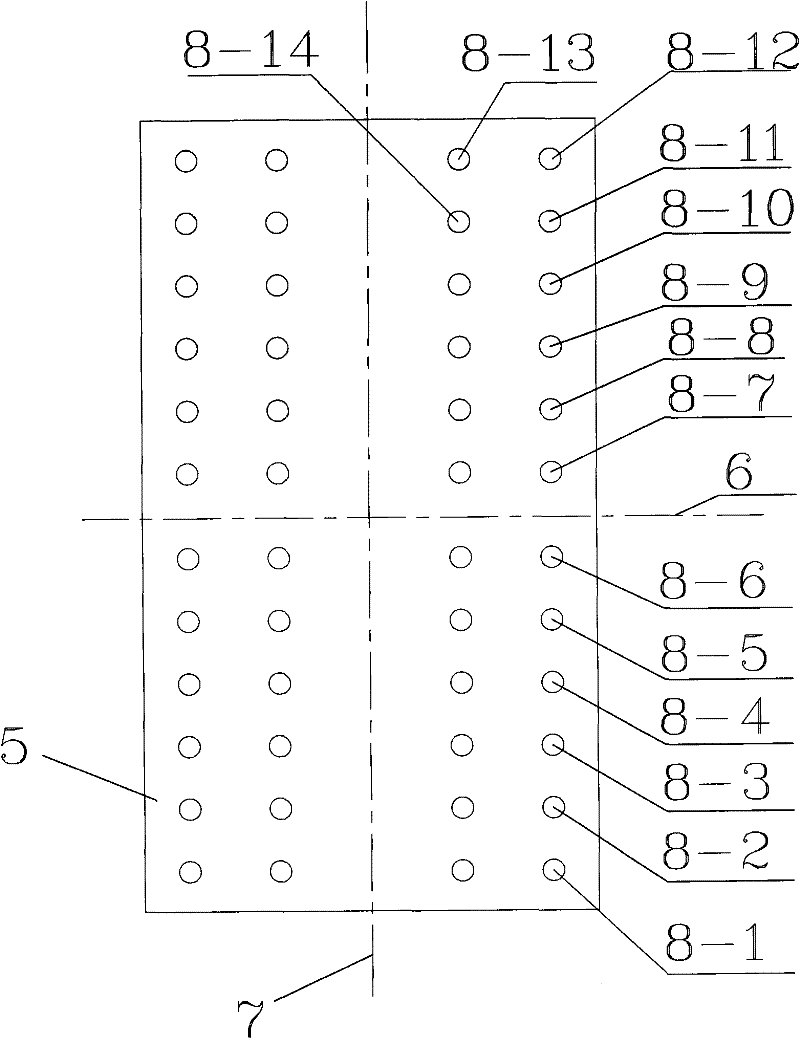

[0030] The invention relates to a method for forming a high-strength bolt hole drilling mold for a CDQ body frame structure, specifically: according to the characteristics of the CDQ body frame, several sets of positioning templates that meet the process accuracy are made by using a drilling and milling machine, and then the templates are used as a reference for The connection plate, H-shaped steel flange plate and web plate that need to be fabricated are centered and drilled on the same node. The method comprises the steps and method of making a drilling template positioning template, using the drilling template to drill the flange plate and web plate of the H-shaped steel member, and connecting the H-shaped steel member.

[0031] The present invention will be further described below in conjunction with implementation examples and accompanying drawings.

[0032] 1. Production of drilling template 5

[0033] Making a precision drilling template 5 (template for short) is a pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com