Mine anti-explosion diesel engine railless free-wheeled vehicle front axle suspension system

An explosion-proof technology for trackless rubber-tyred vehicles and mines, which is applied to locomotives, suspensions, vehicle components, etc., and can solve bumps, front axle splints, spring breakage of connecting bolts, reliability, service life, stability, passability, etc. The index requirements are particularly harsh and other issues, to achieve the effect of avoiding hard collision, good shock absorption effect and reasonable force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Hereinafter, the present invention will be described in detail with reference to the accompanying drawings.

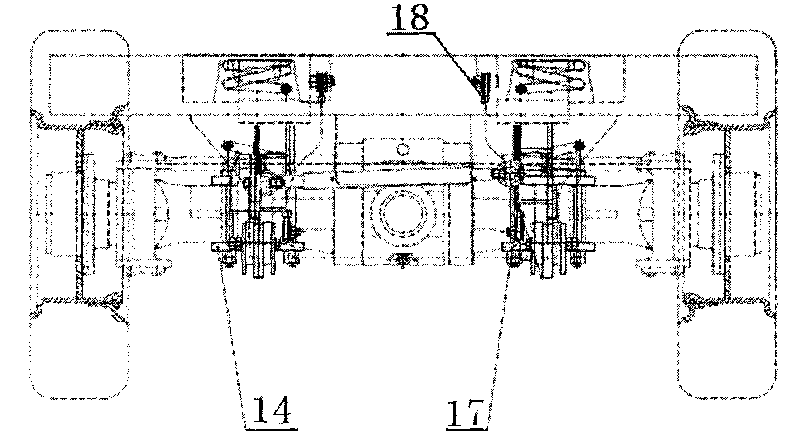

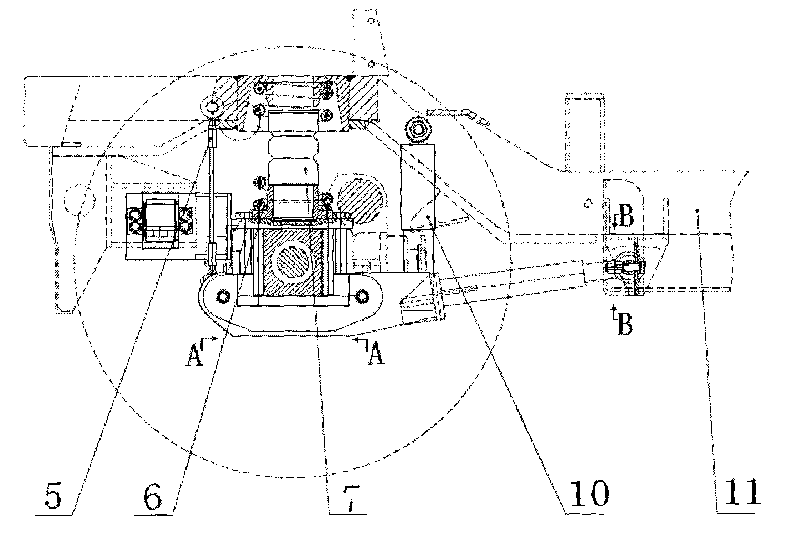

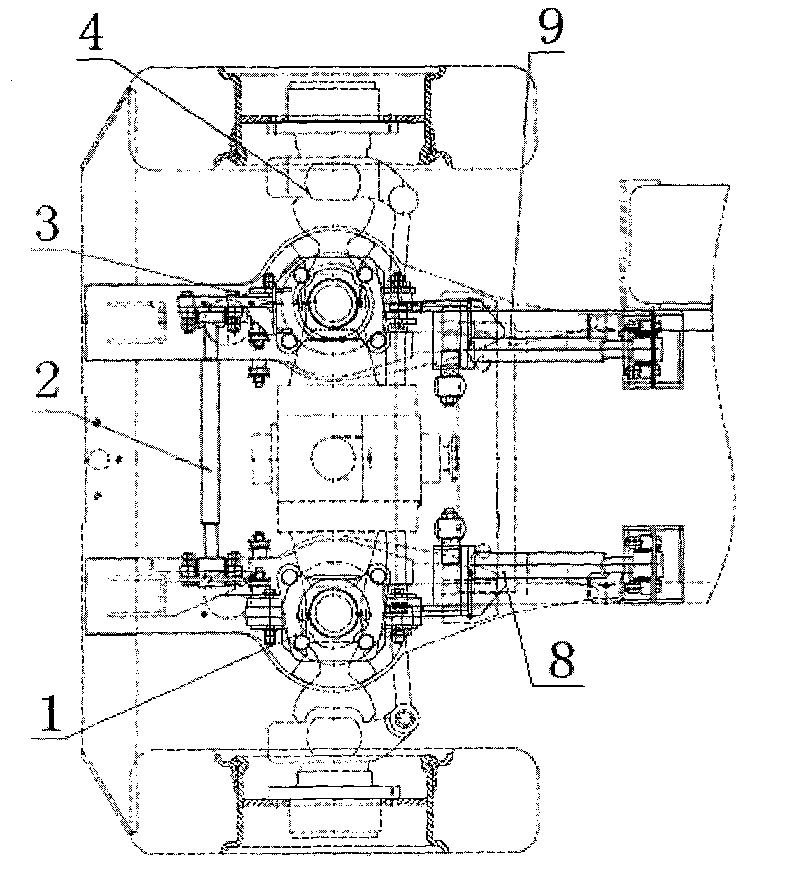

[0015] Such as figure 1 , figure 2 and image 3 As shown, according to the mine explosion-proof diesel engine trackless rubber-tyred vehicle front axle suspension device in the present invention, comprises the following several parts: left spring support 1, front axle tie rod 2, right spring support 3, front axle 4, front Bridge wire rope 5, front pressure spring 6, front damping rubber 7, left push rod 8, right push rod 9, shock absorber 10, vehicle frame 11, limit sleeve 12, push rod rubber block 13, right splint 14, block Ring 15, shaft 16, left splint 17, sleeve 18,

[0016] The front axle 4 is installed on the left push rod 8 and the right push rod 9 hinged with the vehicle frame 11 at one end, the left push rod 8 and the right push rod 9 are hinged with the vehicle frame 11 through the shaft 16, and the outside of the shaft 16 is provided with a retain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com