Ratchet wrench

A ratchet wrench and ratchet mechanism technology, applied in the field of ratchet wrenches, can solve the problems of narrow use range and small torque, and achieve the effect of wide use range and large torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

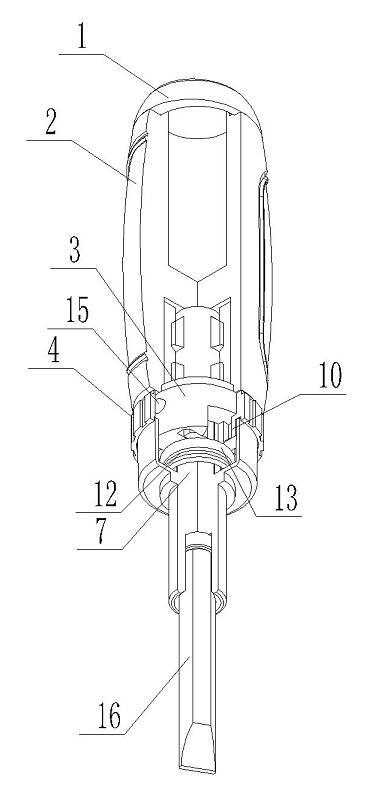

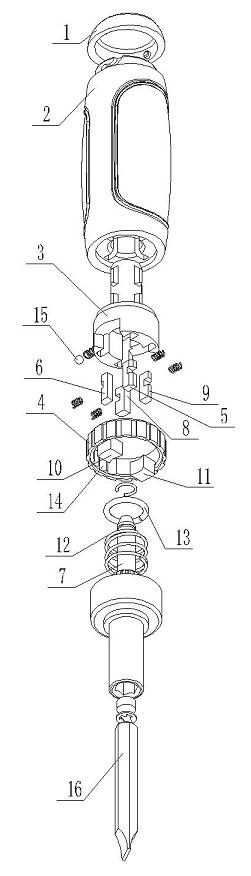

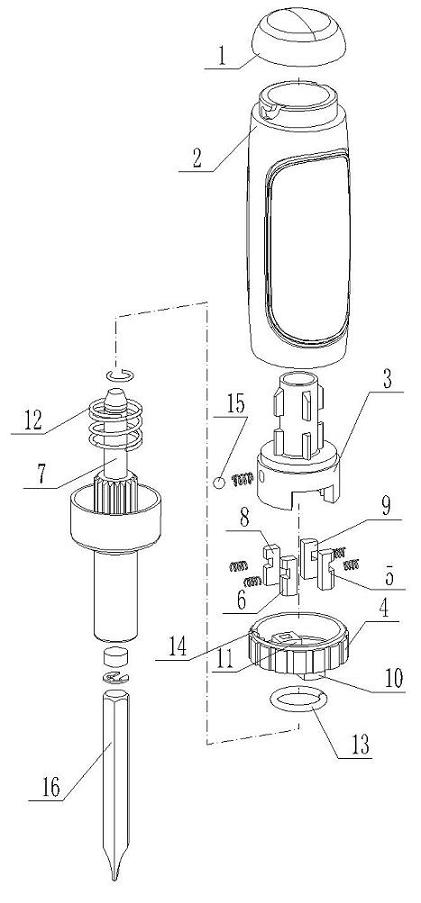

[0016] The present invention will be further described below in conjunction with accompanying drawing.

[0017] The ratchet wrench of the present invention includes a handle 2, a ratchet mechanism and a tool bar 16 sequentially connected from top to bottom, and the ratchet mechanism includes a handle column 3, a reversing member 4, a first tooth 5, a second tooth 6 and a tooth ratchet 7 , the first tooth 5 and the second tooth 6 are elastically installed on the handle column 3, the reversing member 4 is sleeved on the handle column 3, the teeth on the tooth ratchet 7 are arranged on the outer edge of the tooth ratchet 7, and the tooth ratchet 7 is connected to the handle column 3 relatively rotatable fitting connection, it also includes a third tooth 8 and a fourth tooth 9, the third tooth 8 and the fourth tooth 9 are elastically mounted on the stem 3, the first tooth 5, the second tooth 6, The third tooth 8 and the fourth tooth 9 are distributed sequentially along the circumf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com