Biaxial stretched polyethylene protective film

A polyethylene protective film, biaxial stretching technology, applied in the field of packaging films, can solve the problems of poor toughness, can not effectively protect precision instruments, etc., and achieve the effect of good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

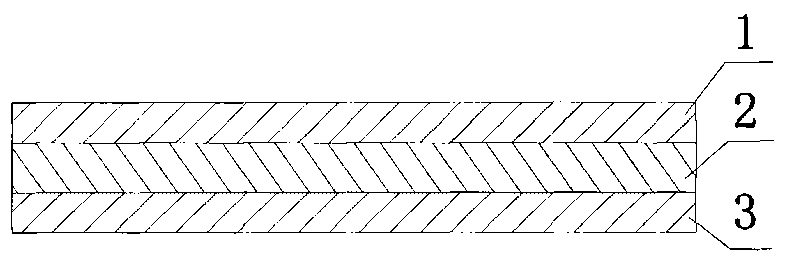

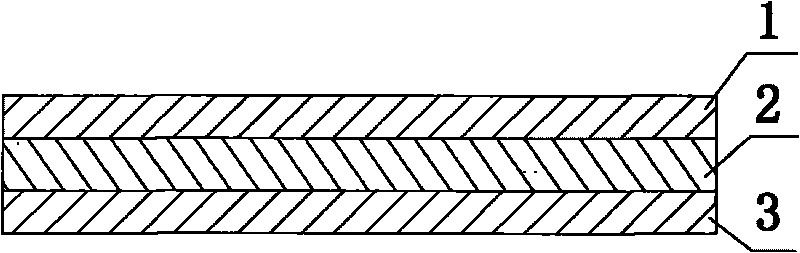

[0013] like figure 1 As shown in the figure, the biaxially oriented polyethylene protective film consists of a functional layer 1, a core layer 2 and a sub-functional layer 3. The core layer 2 is located between the functional layer 1 and the sub-functional layer 3. The functional layer 1, the core layer 2 and The secondary functional layer 3 is integrated by biaxial stretching after co-extrusion (extrusion temperature is 180-210°C, using the existing co-extrusion and biaxial stretching process);

[0014] The material of the functional layer 1 is composed of low density polyethylene, metallocene polyethylene (linear), anti-sticking agent and slip agent, and the mass percentage of each component is: low density polyethylene 60%, metallocene polyethylene Ethylene 35%, anti-sticking agent 3%, slip agent 2%;

[0015] The material of the core layer 2 is metallocene polyethylene;

[0016] The material of the secondary functional layer 3 is composed of ethylene-vinyl acetate copoly...

Embodiment 2

[0024] It is basically the same as Example 1, except that the anti-blocking agent is talc, and the slipping agent is oleic acid amide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com