Performance tester of diesel engine oil pump assembly

A test device and oil pump technology, applied in pump testing, internal combustion engine testing, machine/engine, etc., can solve problems such as polluting the environment, difficulty in fixing the oil pump, wasting oil, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

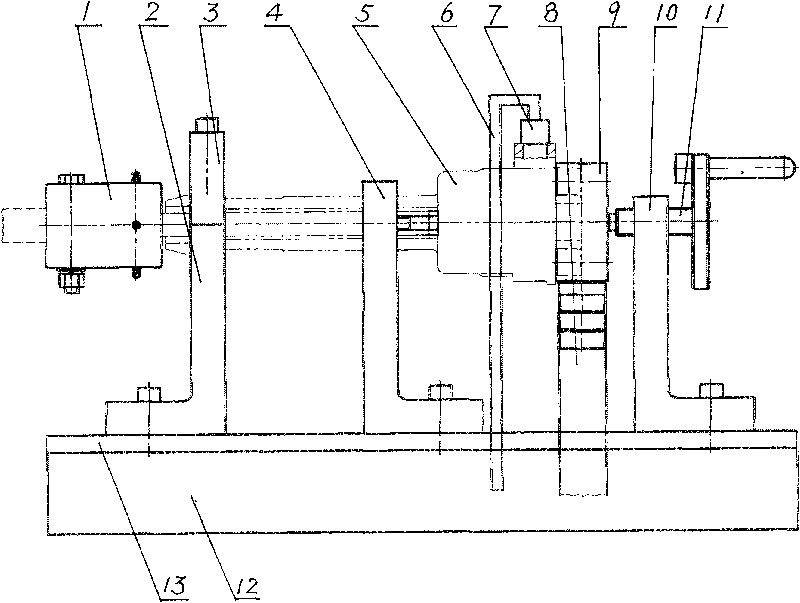

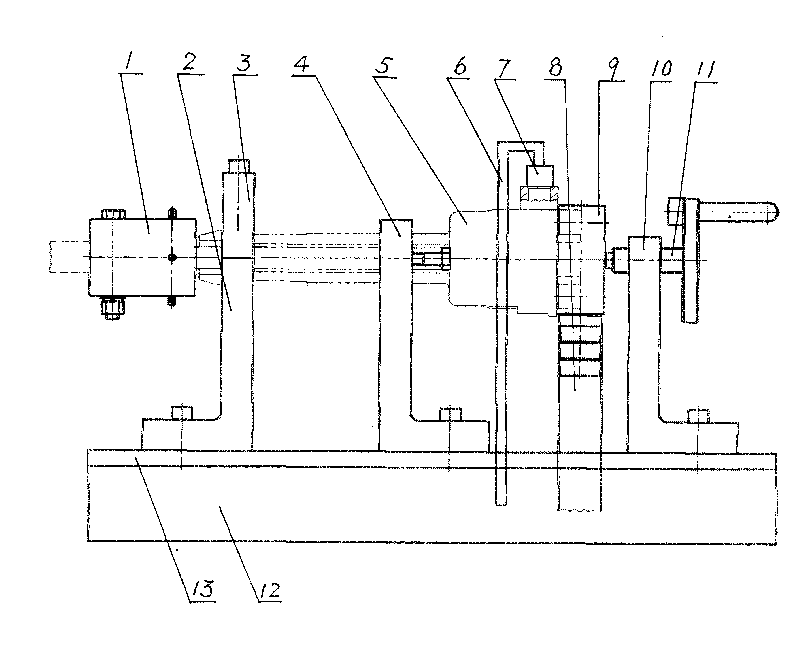

[0008] Referring to the accompanying drawings, the base plate 13 is provided with a front support 2 and a rear support 4. Before the front support, there is a shaft sleeve 1 connected to the output shaft of the supporting motor. After the rear support, an oil inlet pipe 8 and an oil inlet joint 9 are provided. The oil outlet pipe 6, the oil outlet joint 7, and the oil inlet joint 9 are connected with the pressing mechanism. The pressing mechanism is composed of a bracket 10 and a manual screw 11. The front support 2 is provided with a reversible semicircular pressing block 3 for Compress the drive shaft housing of the oil pump 5, and the oil inlet and outlet pipes stretch into the oil pool 12 below the base plate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com