Hollow fiber membrane for humidifier and method for manufacturing the same

一种纤维膜、湿润器的技术,应用在化学仪器和方法、最终产品制造、可持续制造/加工等方向,能够解决中空纤维膜低亲水性、湿润性能不令人满意、中空纤维膜耐湿热性能低等问题,达到优越亲水性、优良防交叉性、低成本的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Hereinafter, an embodiment of the present invention will be described in detail with reference to the accompanying drawings.

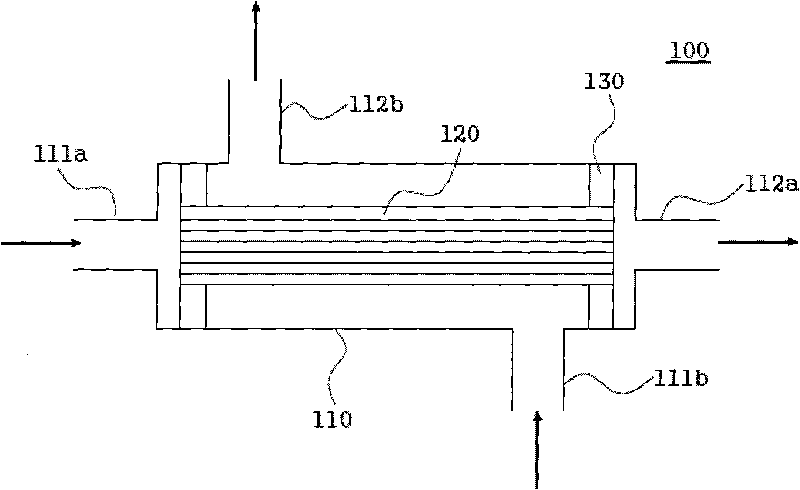

[0024] figure 1 is a schematic diagram illustrating a humidifier for a fuel cell according to an embodiment of the present invention.

[0025] Such as figure 1 As shown, a humidifier for a fuel cell 100 according to an embodiment of the present invention has a housing 110 housing a bundle of a plurality of hollow fiber membranes 120 . The first inlet 111a is located at one side of the housing 110, and a reactant gas (not shown) supplied to the fuel cell enters through the first inlet 111a. The first outlet 112a is located on the other side of the housing 110, and the reactant gas is discharged through the first outlet 112a.

[0026] Both ends of the bundle of hollow fiber membranes 120 are respectively fixed to both sides of the housing 110 by adhesive 130 . The adhesive 130 blocks air flow between the middle of the housing 110 and any one o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com