Method for starting the combustion engine during a load shift in parallel hybrid vehicles

A technology for starting a hybrid vehicle and an internal combustion engine, which is applied to the arrangement of multiple different prime movers of a hybrid vehicle and a general power plant, and the use of engine-driven traction, etc., can solve problems such as interruption of pulling force, and achieve high shifting comfort. , Improve comfort and achieve the effect of speed adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

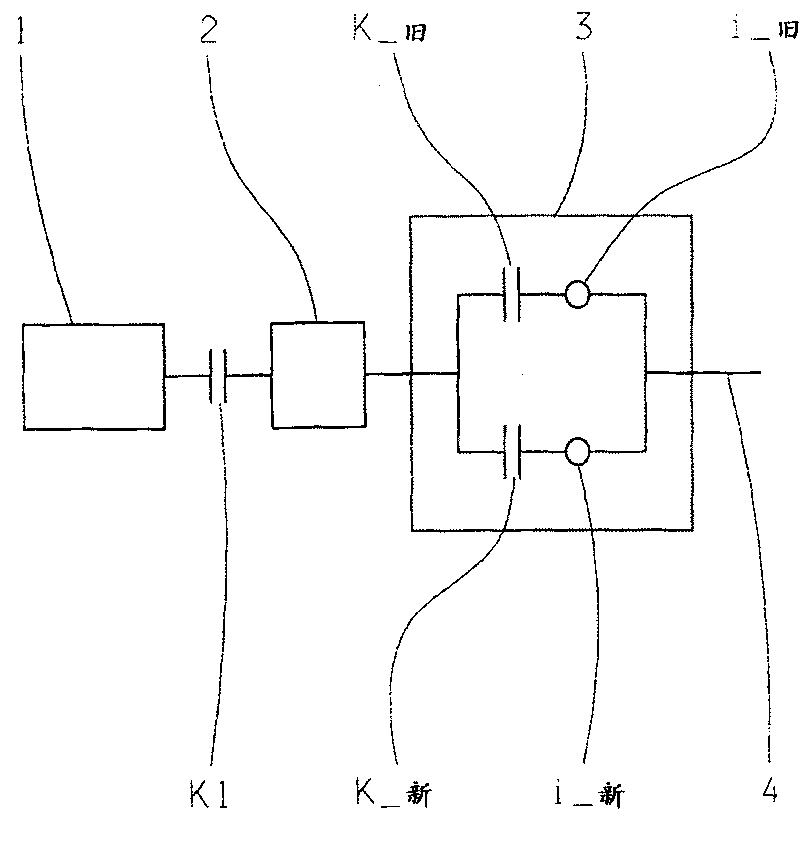

[0026] Such as figure 1 As shown, the drive train of a parallel hybrid vehicle comprises an internal combustion engine 1 and at least one electric machine 2, the electric machines are switched on sequentially, wherein the internal combustion engine 1 can be disengaged from the electric machine 2 and thus the drive train by opening a clutch K1 connect.

[0027] After the electric machine 2 in the direction of power flow, a load-controlled transmission 3 is arranged, as shown in a simplified schematic diagram for illustrating the method of the present invention, the load-controlled transmission includes a new gear for the new gear to be engaged, an approaching An active clutch K_new and a disengaging clutch K_old for the old gear, each clutch or each gear is assigned a gear stage with the gear ratio i_new or i_old. exist figure 1 In , the driven end of the load control transmission 3 is denoted by reference numeral 4 .

[0028] As already mentioned, according to the invention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com