Tobacco field ridging machine automatically protecting leaves

A soil cultivator and tobacco field technology, which is applied in the fields of land preparation machinery, agricultural machinery and implements, etc., can solve the problems such as crushing tobacco leaves by soil cultivation, and achieve the effects of reducing production input, reducing production costs, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

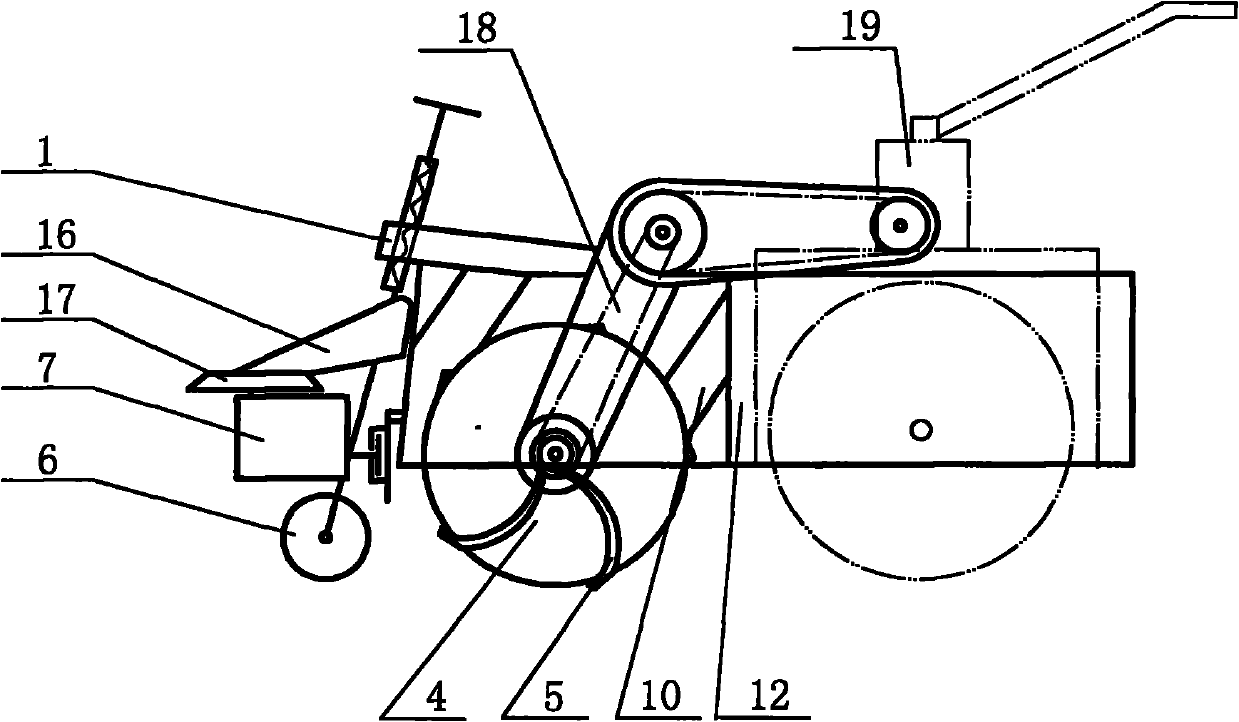

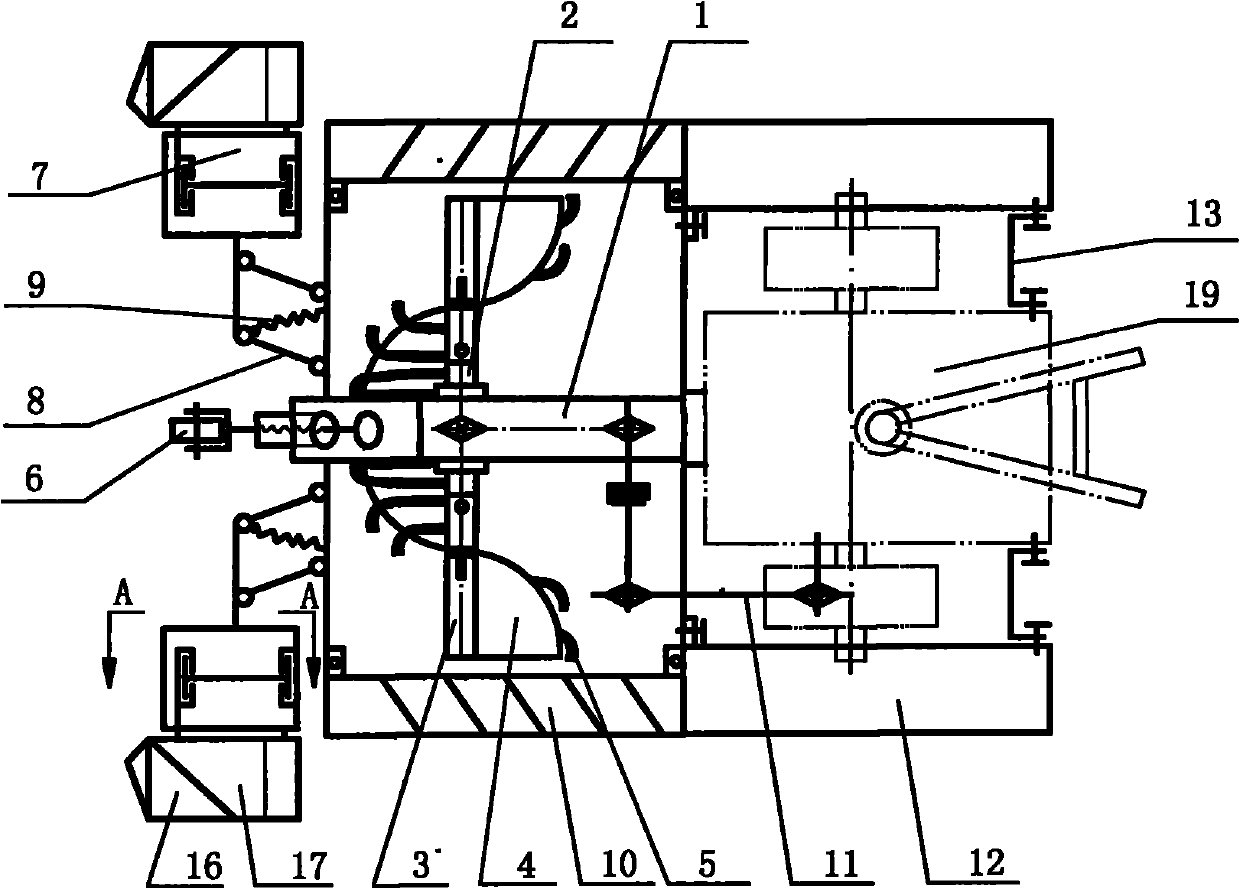

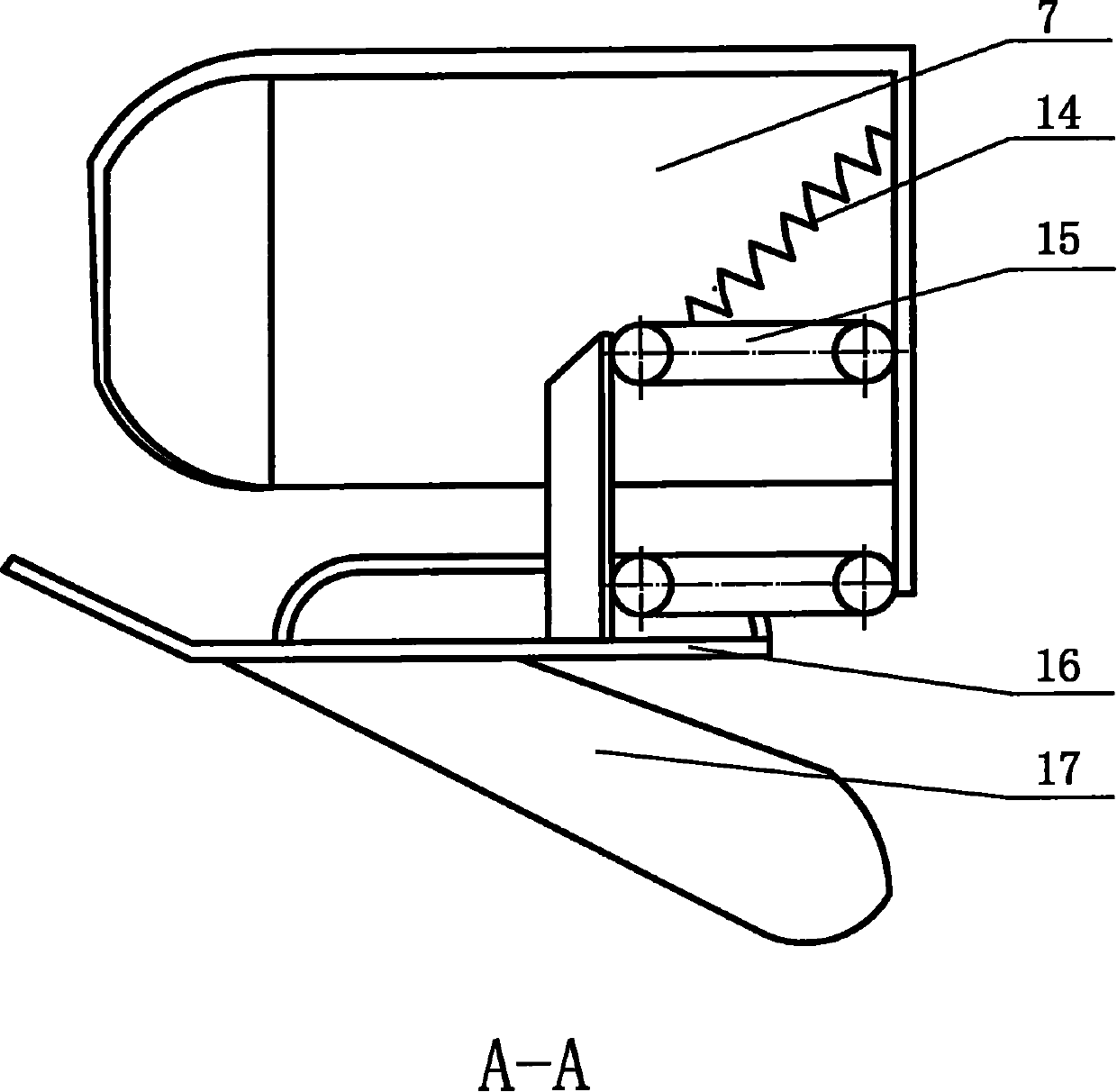

[0012] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0013] Connect the drive arm (18) on the frame (1), the drive shaft (2) is hinged below the drive arm (18), and the drive shaft (2) both sides are respectively fixedly connected with an auger shaft (3), and two auger shafts ( 3) The helical blades (4) with a rising angle of 18° are fixedly connected on the top respectively, and five rotary tillers (5) with equal spacing are respectively installed on the inner side of the helical blades (4), and five rotary tillers (5) with equal spacing are installed on the inner sides of the helical blades (4). The frame is respectively sleeved with the leaf guard (10), and the leaf guard (12) is respectively connected on the frame (1) behind the leaf guard (10), and the other end of the leaf guard (12) passes through the connecting rod (13 ) is connected with the tractor (19), and two groups of horizontal parallel four-bar mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com