An automatic braking device for rope transmission

A technology of automatic braking and rope transmission, applied in safety belts, life-saving equipment, etc., can solve the problems of casualties, large methods, and low safety, and achieve the effects of ensuring life safety, simple structure, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

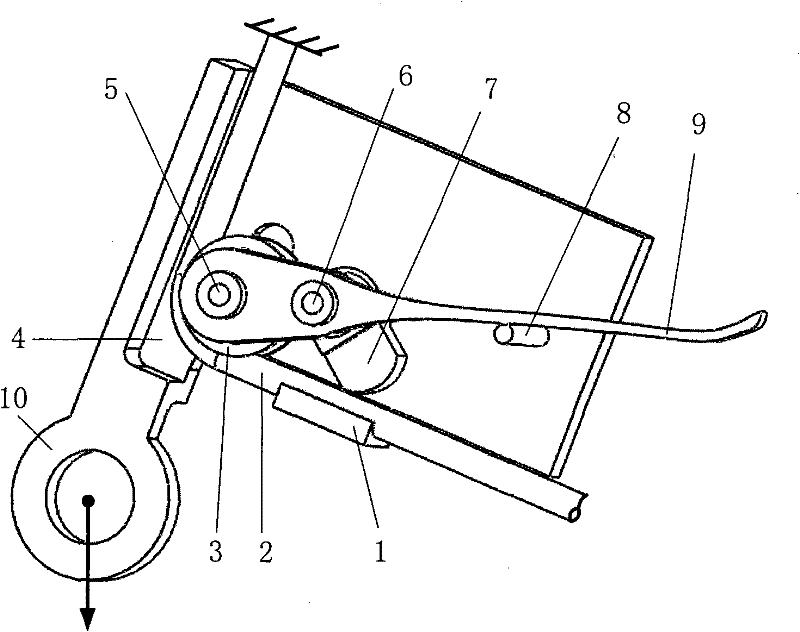

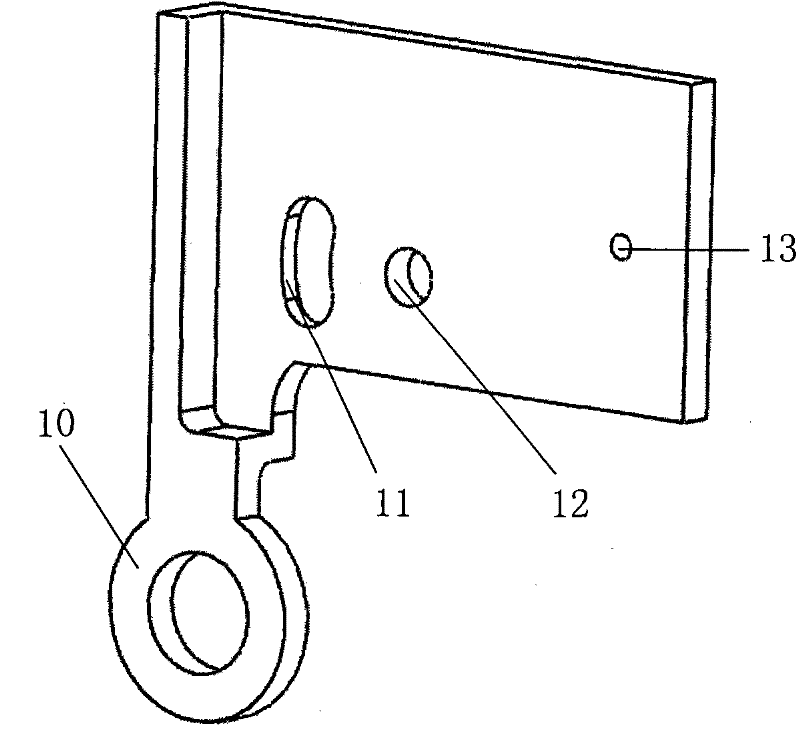

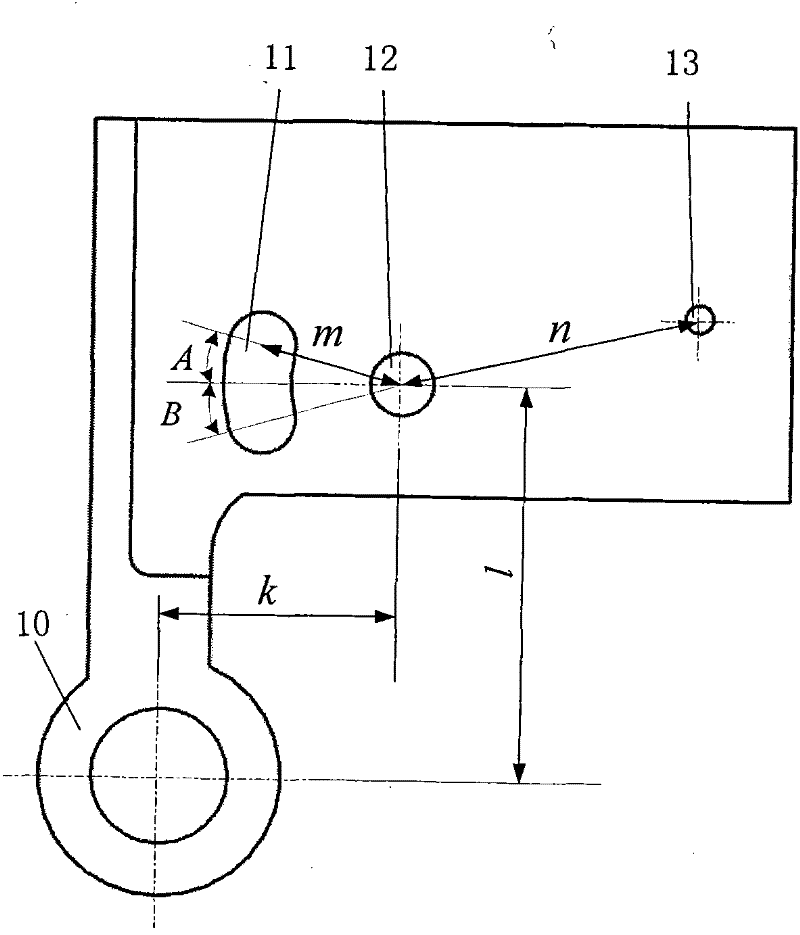

[0011] The automatic braking device of the rope transmission that the present invention proposes, its structure is as follows: figure 1 As shown, it includes base plate 4, steering wheel 3, briquetting block 7, pressure groove 1, handle 9 and stop pin 8. One side bottom of base plate 4 is provided with the annulus 10 of hanging weight, has movable shaft hole 11, fixed axis hole 12 and stop pin hole 13 on the base plate 4, and pressure groove 1 is fixed on the bottom of base plate 4. One end of the handle 9 and the steering wheel 3 are coaxially fixed on the moving shaft 5, and the moving shaft 5 is inserted in the oblong moving shaft hole 11. The middle part of the handle 9 and the briquetting block 7 are fixed in the fixed shaft hole 12 through the fixed shaft 6, the stop pin 8 is inserted in the stop pin hole 13, one end of the briquetting block 7 is relatively fixed with the moving shaft 6, and the other end of the handle 9 rests on the on the stop pin 8.

[0012] In the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com